Method for capturing carbon dioxide in flue gas of power plant

A carbon dioxide and flue gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low capture efficiency, achieve the effects of reducing manufacturing costs, controlling corrosion, and promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

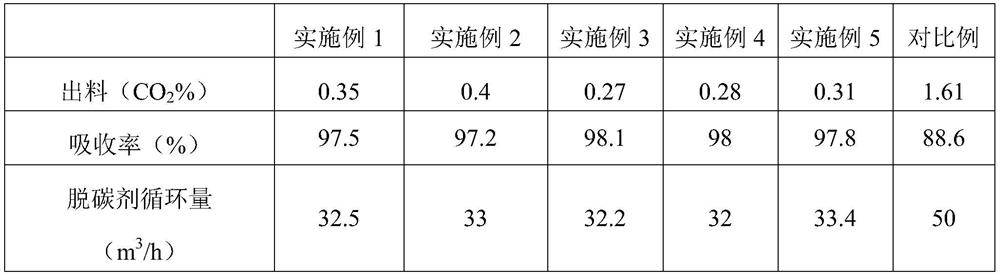

Examples

Embodiment

[0034] A method for capturing carbon dioxide in power plant flue gas, comprising the following steps:

[0035] Step 1: remove the mechanical impurities contained in the flue gas of the power plant by gravity sedimentation, and then pass the removed flue gas through activated carbon, and use the activated carbon to filter out the free water and sulfur dioxide in the flue gas of the power plant to obtain filtered flue gas. The temperature of the filtered flue gas at the time is 68-80°C.

[0036] Step 2: pressurize the filtered flue gas to 5.7Mpa, and then guide it into the cooler to cool to 15°C.

[0037] Step 3, the cooled and pressurized filtered flue gas is introduced from the bottom of the decarbonization absorption tower, and the semi-lean amine liquid is introduced from the upper part of the decarbonization absorption tower, and the filtered flue gas and semi-lean amine liquid will be in the decarbonization absorption tower The relative impact occurs in the interior, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com