A kind of preparation method of vanadium iron spinel

A spinel, ferrovanadium technology, applied in chemical instruments and methods, vanadium oxide, iron compounds and other directions, can solve the problems of difficult preparation of ferrous oxide, high preparation cost, difficult storage and the like, and achieves easy acquisition and preparation method. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

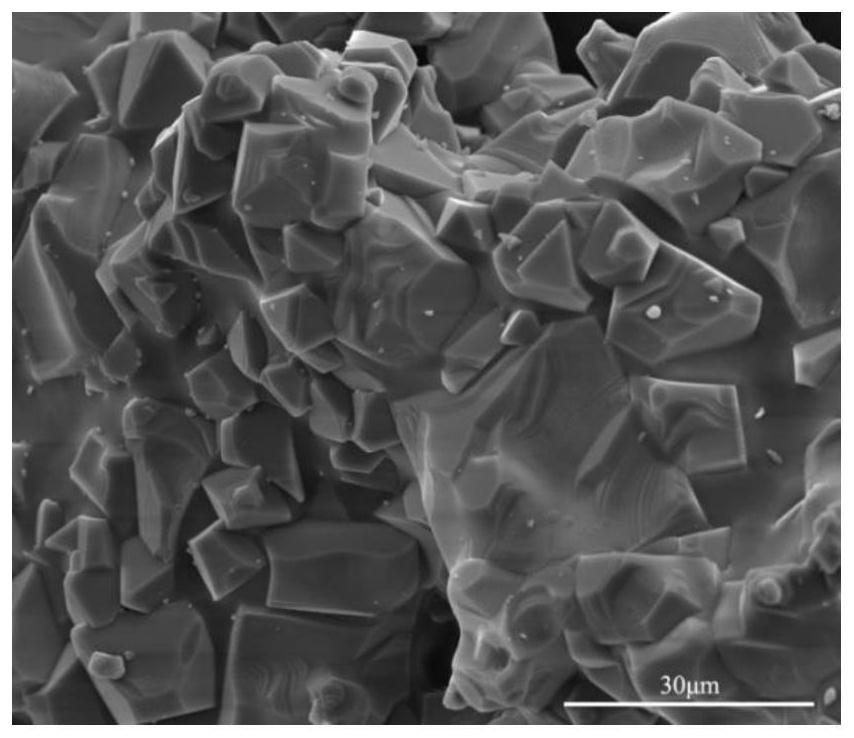

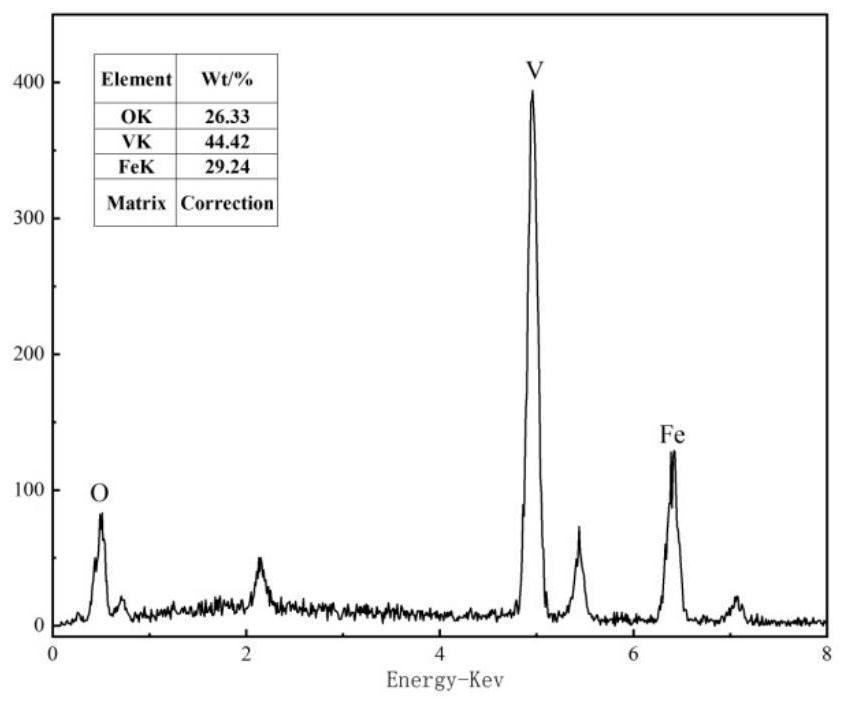

[0028] The invention provides a preparation method of ferrovanadium spinel, comprising:

[0029] Mixing vanadium trioxide and ferrous oxalate to obtain a mixture;

[0030] tableting the mixture to obtain flakes;

[0031] The flakes are heated to obtain ferrovanadium spinel.

[0032] In the present invention, the vanadium trioxide is preferably vanadium trioxide powder; the particle size of the vanadium trioxide powder is preferably 200-300 mesh, more preferably 220-280 mesh, more preferably 240- 260 mesh, most preferably 250 mesh; the ferrous oxalate is preferably ferrous oxalate powder, and the particle size of the ferrous oxalate powder is preferably 200-300 mesh, more preferably 220-280 mesh, more preferably 240 mesh ~260 mesh, most preferably 250 mesh.

[0033] In the present invention, the mass ratio of the vanadium trioxide and ferrous oxalate is preferably (35-45): (55-65), more preferably (38-42): (58-62), most preferably 40:60.

[0034] In the present invention, ...

Embodiment 1

[0059] Accurately weigh 4g of vanadium trioxide powder and 6g of ferrous oxalate powder according to the weight ratio of 40:60, then put the two into an alumina crucible with a diameter of 3cm and cover with a rubber cork; Put it into a small automatic stirrer and rotate to make the sample fully mixed.

[0060] The mixed mixture in the crucible is made into circular slices with a diameter of about 2 cm by using a tablet press.

[0061] Use alcohol to scrub the inner wall of the vacuum induction melting furnace. After the alcohol is completely volatilized, put the alumina crucible with the thin sample on the heating base in the furnace, and close the furnace door; the furnace is evacuated, and then argon gas is introduced into the furnace. The inside of the furnace reaches the standard atmospheric pressure, and then the furnace is evacuated again; this is repeated three times to ensure that there is no air left in the furnace and a vacuum environment is maintained.

[0062] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com