Method for strengthening flotation separation of micro-fine particle copper-lead bulk concentrate through combined inhibitor

A combination of depressant and mixed concentrate technology, applied in flotation, solid separation, etc., can solve the problems affecting the effect of flotation, achieve strong inhibitory effect, strengthen the inhibitory effect, and strengthen the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

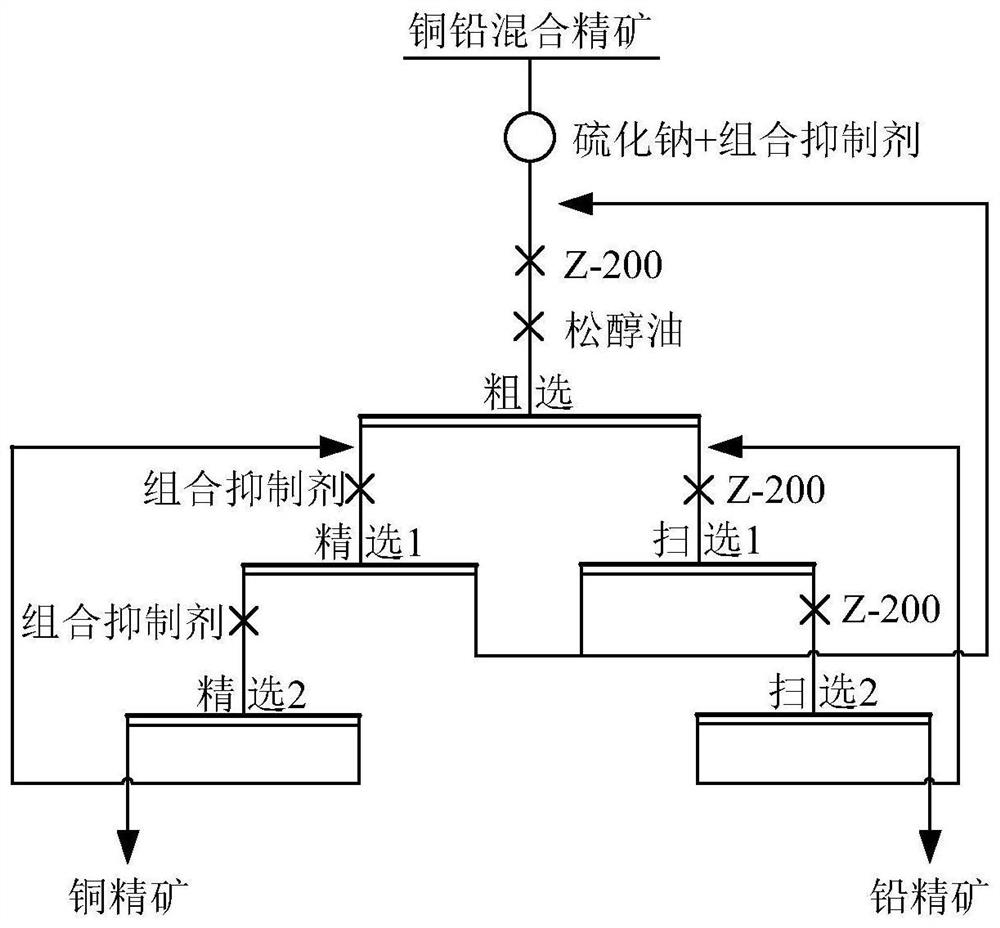

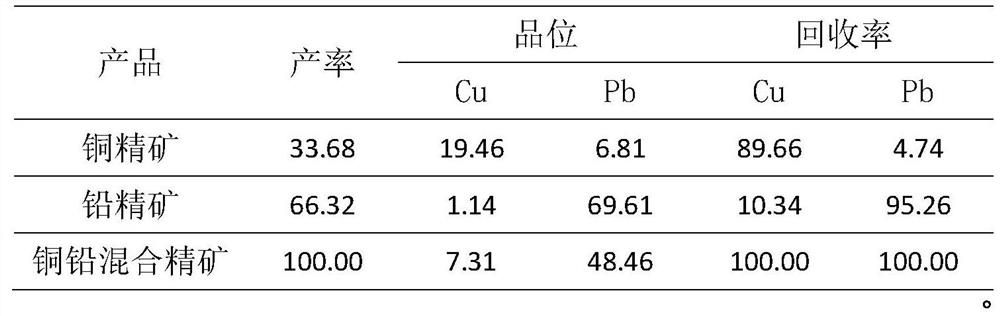

[0029] A copper-lead mixed concentrate contains 7.31% copper and 48.46% lead. The results of technological mineralogy show that the main metal minerals in this copper-lead mixed concentrate are galena, chalcocite, chalcopyrite, pyrite and a small amount of Bornite. Cu and Pb metals are 74.35% and 76.82% respectively at -0.038mm particle size. Adopt the flotation separation process provided by the present invention and combined depressant, carry out laboratory small-scale closed-circuit test to this ore sample, the concrete steps of test are as follows:

[0030] (1) Grind the copper-lead mixed concentrate first, add sodium sulfide and tannic acid + sodium metabisulfite to the grinding, and the dosage is 100g / t, 110g / t, 1200g / t respectively, to obtain the grinding overflow product ;

[0031] (2) Add Z-200 0.4g / t and terpineol oil 20g / t successively after pulping the overflow product of grinding, and conduct a rough separation;

[0032] (3) Sweep the rough tailings twice, add ...

Embodiment 2

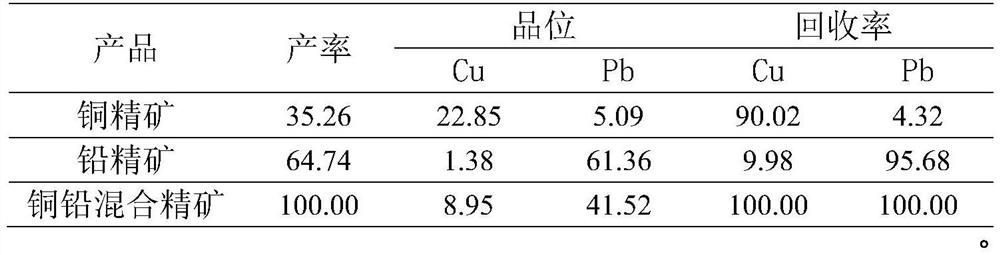

[0039] A copper-lead mixed concentrate contains 8.95% copper and 41.52% lead. The results of technological mineralogy show that the main metal minerals in this copper-lead mixed concentrate are galena, chalcocite, chalcopyrite and pyrite. Cu and Pb metals are 74.07% and 78.26% respectively at -0.038mm particle size. Adopt the flotation separation process provided by the present invention and combined depressant, carry out laboratory small-scale closed-circuit test to this ore sample, the concrete steps of test are as follows:

[0040] (1) Grind the copper-lead mixed concentrate first, add sodium sulfide and tannic acid + sodium thiosulfate to the grinding, and the dosage is 110g / t, 90g / t, 900g / t respectively, to obtain the grinding overflow Flow product;

[0041] (2) Add Z-200 0.6g / t and terpineol oil 25g / t successively after slurrying the overflow product of grinding, and conduct a rough separation;

[0042] (3) Sweep the rough tailings twice after roughing, add 0.3g / t Z-20...

Embodiment 3

[0049] A copper-lead mixed concentrate contains 5.14% copper and 53.39% lead. The results of technological mineralogy show that the main metal minerals in this copper-lead mixed concentrate are galena, chalcopyrite and pyrite. Cu and Pb metals are 78.32% and 80.25% respectively at -0.038mm particle size. Adopt the flotation separation process provided by the present invention and combined depressant, carry out laboratory small-scale closed-circuit test to this ore sample, the concrete steps of test are as follows:

[0050] (1) Grind the copper-lead mixed concentrate first, add sodium sulfide and tannic acid + sodium pyrosulfite + sodium thiosulfate to the grinding, the dosage is 105g / t, 150g / t, 1600g / t, 1400g respectively / t, to obtain the grinding overflow product;

[0051] (2) Add Z-200 0.5g / t and terpineol oil 22g / t successively after slurrying the overflow product of grinding, and carry out a rough separation;

[0052] (3) Sweep the rough tailings twice after roughing, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com