High-emissivity infrared energy-saving high-entropy material with perovskite structure and preparation method thereof

A perovskite structure, high emissivity technology, applied in chemical instruments and methods, sustainable manufacturing/processing, inorganic chemistry, etc. It can solve problems such as inter-particle scattering, and achieve the effects of reducing the mean free path, enhancing nonlinear vibration, and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

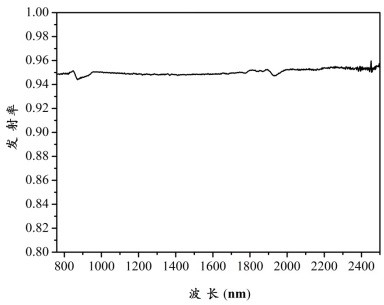

[0023] Embodiment 1: Carry out batching according to molar ratio La:Cr:Mn:Fe:Co:Ni=1:0.2:0.2:0.2:0.2:0.2 with lanthanum oxide, cobalt oxide, chromium oxide, iron oxide, manganese oxide, nickel oxide and ball milled for 6 h, dried and calcined in an air atmosphere at 1200 °C for 300 min to cause a high-temperature solid-state reaction to occur, and finally a high-emissivity infrared energy-saving high-entropy material with a perovskite structure was prepared. An entropic material has an emissivity of 0.95.

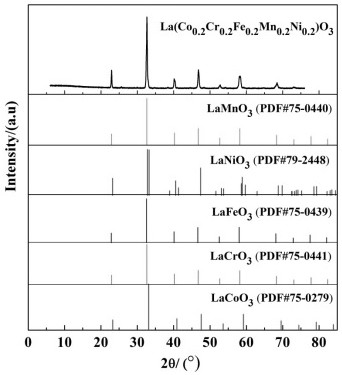

[0024] From figure 1 It can be seen that the diffraction peaks of the high-emissivity infrared energy-saving high-entropy material synthesized in this implementation case are located between the five single components, and almost completely coincide with the diffraction peaks of LaMnO3, and the diffraction peaks are broadened at the same time, indicating that the five elements Solid solution in the crystal lattice is good, the high configuration entropy formed by equimolar...

Embodiment 2

[0026] Embodiment 2: Carry out batching according to molar ratio La:Cr:Mn:Fe:Co:Ni=1:0.2:0.2:0.2:0.2:0.2 with lanthanum oxide, cobalt oxide, chromium oxide, iron oxide, manganese oxide, nickel oxide and ball milled for 24 h, dried and calcined in an air atmosphere at 1400 °C for 360 min to allow a high-temperature solid-state reaction to occur, and finally a high-emissivity infrared energy-saving high-entropy material with a perovskite structure was prepared. The emissivity of entropic materials is 0.91.

Embodiment 3

[0027] Embodiment 3: Carry out batching according to molar ratio La:Cr:Mn:Fe:Co:Ni=1:0.2:0.2:0.2:0.2:0.2 with lanthanum oxide, cobalt oxide, chromium oxide, iron oxide, manganese oxide, nickel oxide and ball milled for 24 h, dried and calcined in an air atmosphere at 1500 °C for 120 min to allow a high-temperature solid-state reaction to occur, and finally a high-emissivity infrared energy-saving high-entropy material with a perovskite structure was prepared. The emissivity of entropic materials is 0.89.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com