Superfine sulfur-containing tailing concrete

A technology of concrete and sulfur tailings, applied in the field of resource utilization of sulfur tailings, which can solve the problems of low market acceptance, immature properties of alkali-activated materials, and affecting the promotion and application of sulfur tailings-based concrete products, etc. To achieve the effect of increasing the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

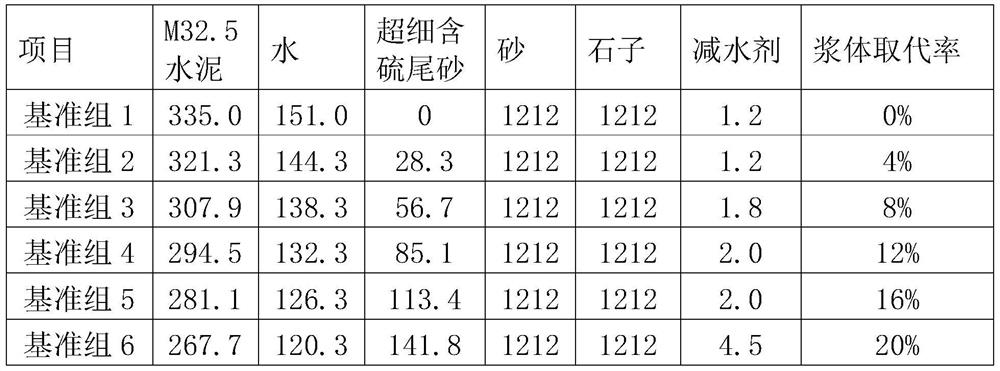

[0025] Embodiment 1: An ultrafine sulfur-containing tailings concrete, including M32.5 cement, ultrafine sulfur-containing tailings, sand, stones, water reducing agent and water. Concrete parts by weight (kg) proportioning ratio as shown in Table 1,

[0026] Table 1

[0027]

[0028] Among them: the density of M32.5 cement is 3.1g / cm 3 ; The fineness modulus of the sand is 2.5; the superfine sulfur-containing tailings pass through a 200 mesh sieve, the average particle size is 76 microns, and the density is 3.06g / cm 3 , sulfur content (converted into SO 3By mass, %) 3.37%; the stone is 10-20mm continuous grain grade limestone; the water is tap water, the density is 1g / cm 3 ; The water reducer is a polycarboxylate high-performance water reducer; the slurry replacement rate is superfine sulfur-containing tail replacing the mortar volume (the volume of M32.5 cement and water).

[0029] Prepare concrete according to the ratio shown in Table 1, pour it into a cubic steel mol...

Embodiment 2

[0034] The invention provides an ultrafine sulfur-containing tailings concrete, which includes M32.5 cement, ultrafine sulfur-containing tailings, sand, stones, water reducing agent and water. Concrete parts by weight (kg) proportioning ratio as shown in table 3,

[0035] table 3

[0036]

[0037]

[0038] Among them: the density of M32.5 cement is 3.1g / cm 3 ; The fineness modulus of the sand is 2.5; the superfine sulfur-containing tailings pass through a 200 mesh sieve, the average particle size is 76 microns, and the density is 3.06g / cm 3 , sulfur content (converted into SO 3 By mass, %) 3.37%; the stone is 10-20mm continuous grain grade limestone; the water is tap water, the density is 1g / cm 3 ; Water reducer is polycarboxylate high performance water reducer. Among them, the slurry replacement rate is the superfine sulfur-containing tail replacing the mortar volume (the volume of M32.5 cement and water).

[0039] Prepare concrete according to the ratio shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com