Structure repairing and reinforcing material for concrete chimney and cooling tower and application of structure repairing and reinforcing material

A technology for strengthening materials and concrete, which is applied in the field of building materials, can solve the problems of large space for improvement, the decline of concrete performance and structural stability, and achieve excellent anti-carbonation, and solve the effects of performance and structural stability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

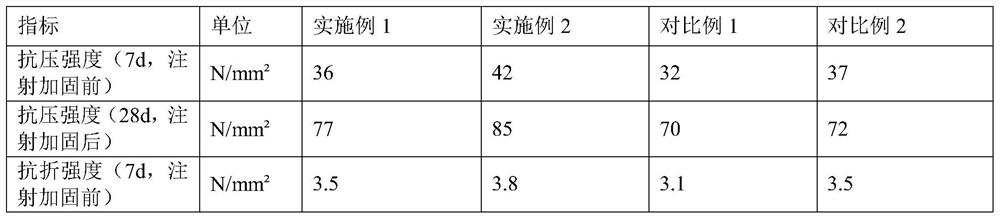

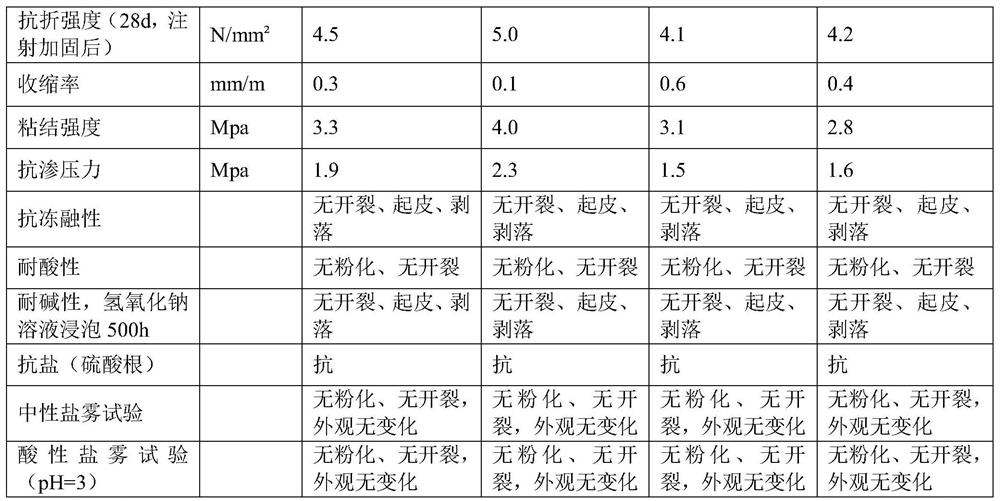

Examples

preparation example Construction

[0028] Preferably, the preparation method of the micron-sized diamine@MOF particles comprises: adding aluminum nitrate and 4,4'-biphenyldicarboxylic acid to the Disperse evenly in water, heat up to 160-200°C, then adjust the pH of the resulting solution to 2-4, and keep it warm for 5-10 hours; after the reaction, filter, wash, dry and pulverize to obtain micron-sized aluminum MOF particles ;Immerse aluminum MOF particles in a diamine solution (isophoronediamine, m-phenylenediamine or m-xylylenediamine), let it stand for 2-4h for adsorption, and centrifuge to obtain micron-sized diamine@MOF particles.

[0029] The concrete grouting liquid includes A component and B component with a mass ratio of (4-4.5): (1.5-2.0), wherein: the A component includes the following components in mass percentage: bismuth with Mw<700 Phenol-A-epichlorohydrin resin 60-68%, glycidyl 12-14 alkyl ether 10-20%, 1,6-hexanediol diglycidyl ether 10-20%, bisphenol F with Mw<700 Epoxy resin 10-20%, 3-(2,3-epo...

Embodiment 1

[0032] A structural repair and reinforcement material for concrete chimneys and cooling towers, comprising base surface repair mortar and concrete grouting liquid. Wherein: the base surface repair mortar includes the following components in mass percentage: 50% of natural quartz sand, and the specific surface area is greater than 12000cm 2 / g Portland cement 48.4%, acrylate / acrylamine / acrylate terpolymer 1.5%, D 95 < 10 micron hydraulic binder (methyl cellulose) 0.05%, polyethylene 0.05%.

[0033] The concrete grouting fluid comprises A component and B component with a mass ratio of 4.23:1.77, wherein:

[0034] The A component includes the following components in mass percentage: 62% of bisphenol-A-epichlorohydrin resin with Mw<700, 12% of glycidyl 12-14 alkyl ether, 1,6-hexanediol dishrinkle Glyceryl ether 12%, bisphenol F epoxy resin with Mw<700 10.5%, 3-(2,3-glycidoxy)propyltrimethoxysilane 3.5%.

[0035] The B component includes the following components in mass percenta...

Embodiment 2

[0037] The difference from Example 1 is only that 2.5% of micron-sized diamine@aluminum MOF particles are used to replace the same amount of natural quartz sand in the base surface repair mortar.

[0038] The preparation method of the micron-sized diamine@MOF particles is as follows: adding aluminum nitrate and 4,4'-biphenyldicarboxylic acid to water with a molar ratio of aluminum element and carboxyl group of 1:1 and dispersing them evenly, heating the to 180°C, then adjust the pH of the resulting solution to 3, and keep it warm for 6 hours; after the reaction, filter, wash, dry and pulverize to obtain micron-sized aluminum MOF particles; impregnate the aluminum MOF particles in a diamine solution (m-phenylene Dimethylamine), let stand for adsorption for 3h, and centrifuge to obtain micron-sized diamine@MOF particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com