Permeable reactive anticorrosive material for concrete chimney and application of permeable reactive anticorrosive material

An osmotic reaction type, anti-corrosion material technology, applied in the direction of anti-corrosion coatings, polyether coatings, building types, etc., can solve problems such as shedding, coatings that cannot exert synergistic effects, and poor anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] The preparation method of the micron-sized diamine@MOF particles comprises: adding aluminum nitrate and 4,4'-biphenyl dicarboxylic acid to water with a molar ratio of aluminum element and carboxyl group of 1: (0.8-1.2) and dispersing Evenly, heat up to 160-200°C, then adjust the pH of the resulting solution to 2-4, and keep it warm for 5-10 hours; after the reaction is completed, filter, wash, dry and pulverize to obtain micron-sized aluminum MOF particles; The MOF particles are immersed in a diamine solution (isophoronediamine, m-phenylenediamine or m-xylylenediamine), allowed to stand for adsorption for 2-4 hours, and centrifuged to obtain micron-sized diamine@MOF particles.

[0084] The base surface reinforcement material is concrete grouting liquid, including A component and B component with a mass ratio of (4-4.5): (1.5-2.0), wherein:

[0085] The A component includes the following components in mass percentage: 60-68% of bisphenol-A-epichlorohydrin resin with Mw<7...

Embodiment 1

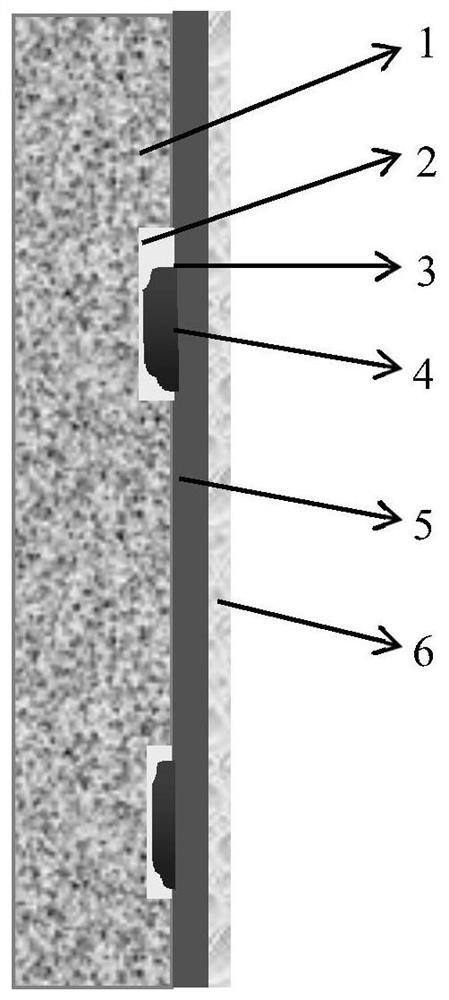

[0095] A osmotic reaction type anticorrosion material for concrete chimneys, including salt-resistant reinforcement material, base surface repair mortar, base surface reinforcement material, bottom layer anticorrosion material and surface layer anticorrosion material sequentially coated or injected on the concrete base surface. in:

[0096] The salt-resistant reinforcing material includes the following components in mass percentage: 3.5% of potassium silicate with a maximum particle size of less than 20nm, 15% of acrylate polymer, 3.5% of polysiloxane, 0.75% of ethoxylated tridecyl alcohol, water balance.

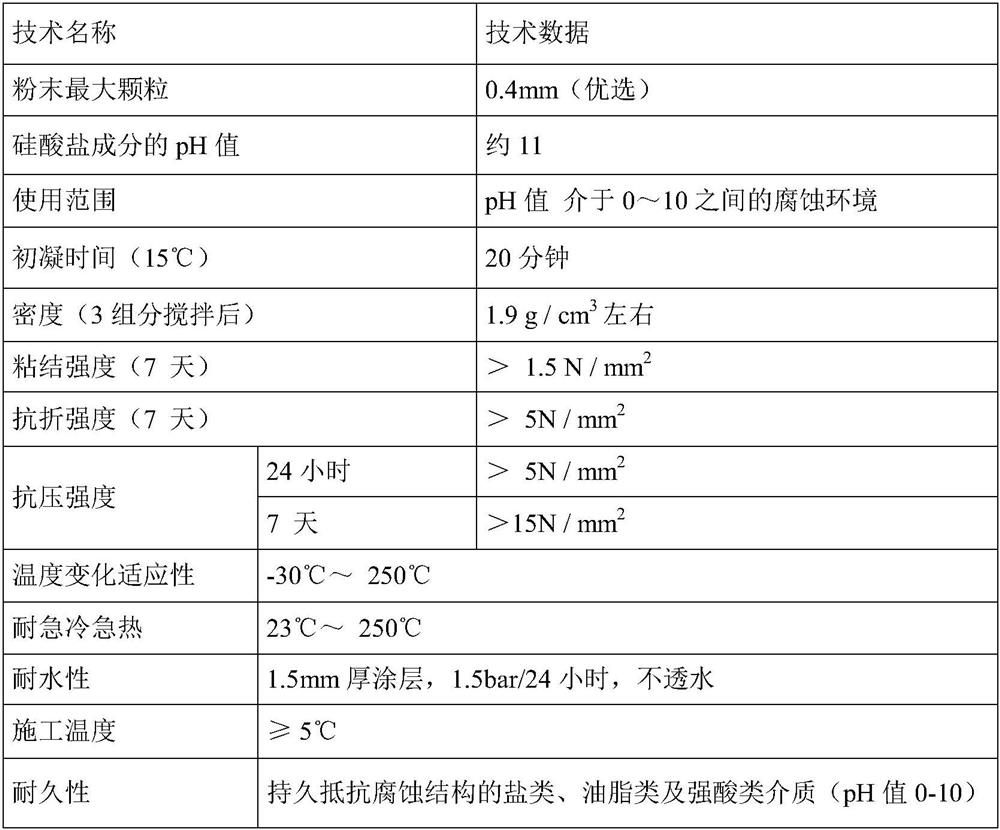

[0097] The technical parameters of the salt-resistant reinforcing material of the present embodiment are shown in the table below:

[0098] technical name Technical data main ingredient polymer, silicate particle diameter 20nm density 1.03g / cm 3

coating surface clear, slightly sticky elongation at break 505% penetration...

Embodiment 2

[0113] A osmotic reaction type anticorrosion material for concrete chimneys, including salt-resistant reinforcement material, base surface repair mortar, base surface reinforcement material, bottom layer anticorrosion material and surface layer anticorrosion material sequentially coated or injected on the concrete base surface. in:

[0114] The salt-resistant reinforcing material includes the following components in mass percentage: 2% of potassium silicate with a maximum particle size of less than 20nm, 20% of acrylate polymer, 2% of polysiloxane, 1% of ethoxylated tridecyl alcohol, Water 75%.

[0115] The bottom anticorrosion material is a polymer silicate heavy anticorrosion material, including A, B and C three components with a mass ratio of 20:4:1: the A component includes the following components in mass percentage: quartz sand 84.5 %, silicon powder 10.0%, aluminum metaphosphate 5.0%, polyethylene 0.5%. The B component includes the following components in mass percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com