Method for continuously extracting essential oil, pectin and hesperidin from orange peel

A technology of hesperidin and orange peel is applied in the field of food processing, which can solve the problems of high pollution and high cost, and achieve the effects of reducing pollution and energy consumption, saving energy consumption and shortening extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the technique of continuous extraction essential oil, pectin and hesperidin in orange peel

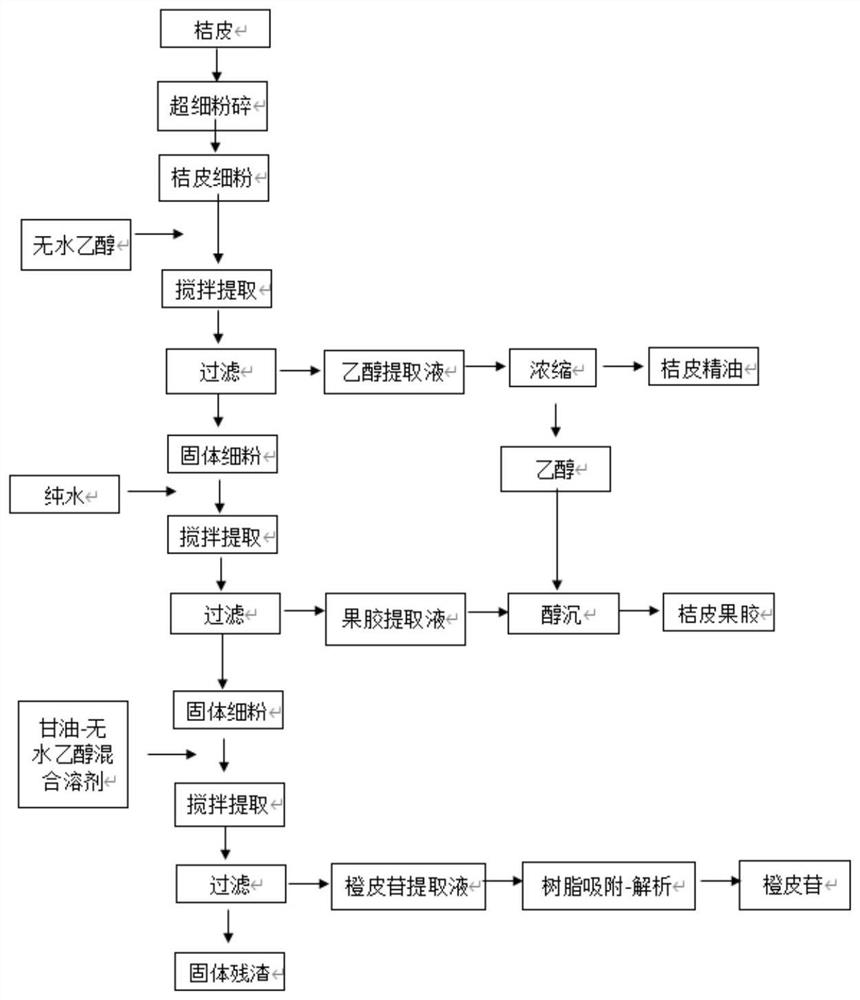

[0051] See the specific process figure 1 ,Specific steps are as follows:

[0052] (1) pulverizing the orange peel into particles with a particle size ranging from 80 to 100 microns;

[0053] (2) Using absolute ethanol as the extractant, mix it with the pulverized orange peel raw material prepared in step (1) according to the solid-liquid ratio of 1:5, stir at 18-25°C for 50 minutes, and filter to obtain the ethanol-extracted The liquid was concentrated and removed by vacuum distillation to obtain dark brown orange peel essential oil after concentration and removal of ethanol;

[0054] The measured essential oil extraction rate is 42% (to the total content); the essential oil contains 150 kinds of volatile components, of which the limonene content accounts for 75%, and other main essential oil components include linalool (accounting for 5%), β-laurel Alkenes (acc...

Embodiment 2

[0059] Embodiment 2: the technique of continuous extraction essential oil, pectin and hesperidin in orange peel

[0060] Specific steps are as follows:

[0061] (1) Pulverizing the orange peel into particles with a particle size ranging from 200 to 300 microns;

[0062] (2) Using absolute ethanol as the extractant, mix it with the crushed orange peel raw material prepared in step (1) according to the ratio of material to liquid at 1:5, stir at 18-25°C for 50 minutes, and filter to obtain the ethanol extract , using vacuum distillation technology to concentrate and remove ethanol to obtain dark brown orange peel essential oil;

[0063] The measured essential oil extraction rate is 30% (to the total content); the essential oil contains 126 kinds of volatile components, of which the limonene content accounts for 78%, and other main essential oil components include linalool (accounting for 3%), β-laurel Alkenes (accounting for 2%), 1,3-dihydroxy-acetone (accounting for 1%), meth...

Embodiment 3

[0068] Embodiment 3: the technique of continuous extraction essential oil, pectin and hesperidin in orange peel

[0069] Specific steps are as follows:

[0070] (1) pulverizing the orange peel into particles with a particle size ranging from 20 to 80 microns;

[0071] (2) Using absolute ethanol as the extractant, mix it with the crushed orange peel raw material prepared in step (1) according to the ratio of material to liquid at 1:5, stir at 18-25°C for 50 minutes, and filter to obtain the ethanol extract , using vacuum distillation technology to concentrate and remove ethanol to obtain dark brown orange peel essential oil;

[0072] The measured essential oil extraction rate is 50% (to the total content); the essential oil contains 153 kinds of volatile components, of which limonene content accounts for 74%, and other main essential oil components include linalool (accounting for 6%), β-laurel Alkenes (accounting for 4%), 1,3-dihydroxy-acetone (accounting for 2%), methyl ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com