Preparation method of CoO-coated carbon nanotube film with HER/OER bifunctional catalytic activity

A carbon nanotube film, bifunctional catalysis technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of inability to meet industrial applications, poor conductivity, high cost of HER catalysts, etc., and achieve good industrial application prospects and low cost. , high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

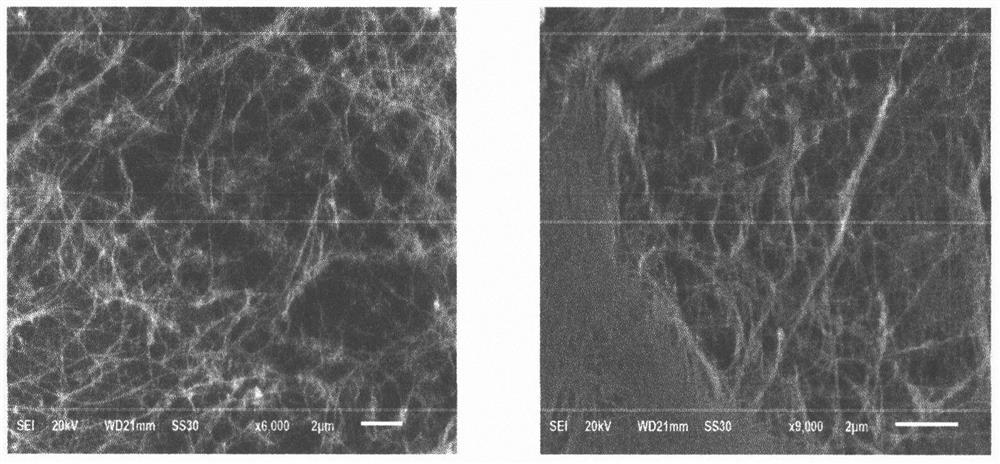

[0025] Example 1: After dissolving 16mmol of cobalt nitrate hexahydrate and 4mmol of 2-methylimidazole in 50mL of deionized water, put them into the reactor together with the carbon nanotube film, and obtain CoO@CNTF at 90°C for six hours Precursor. Wash with deionized water by ultracentrifugation until pH = 7, and then treat at high temperature in a tube furnace for two hours. figure 1 It is the SEM picture of the carbon fiber film. It can be seen that the diameter of a single tube is tens of nanometers, and the thickness distribution is uneven.

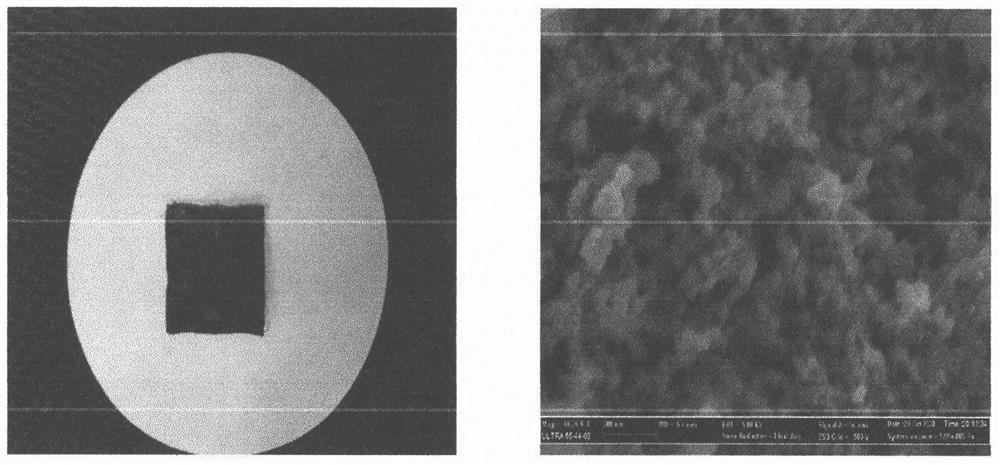

[0026] figure 2 It is (a) physical picture (b) SEM of CoO@CNTF carbonization product. It can be seen that ZIF67 grows on the carbon nanotube film, and the morphology is relatively uniform.

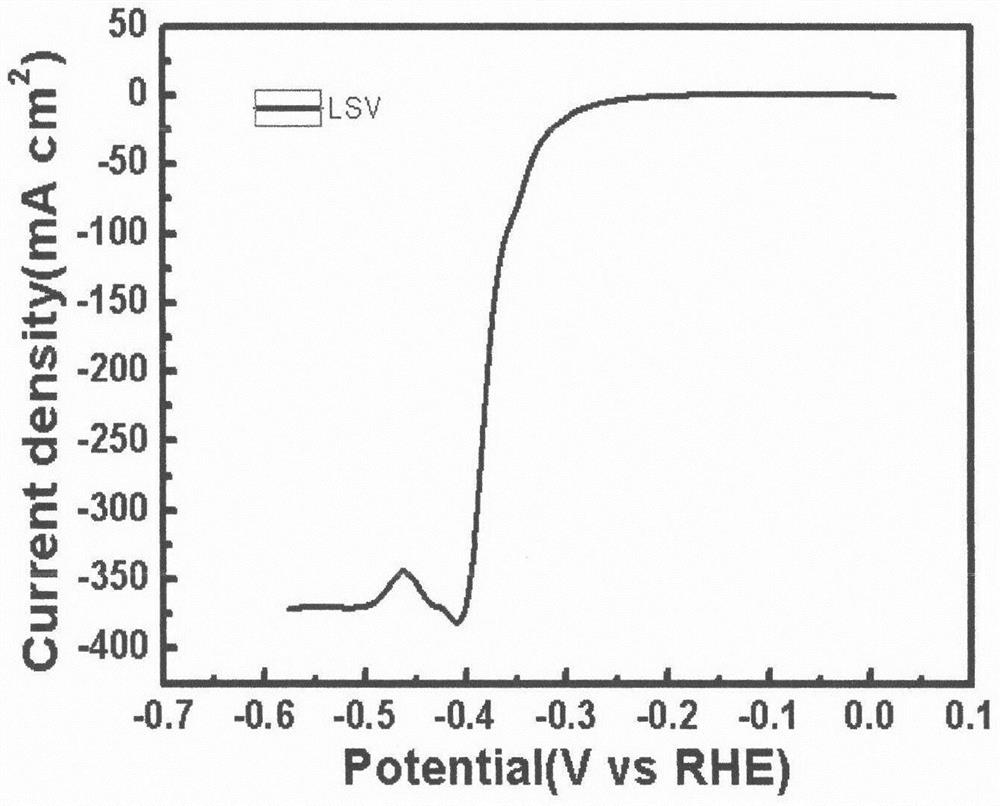

[0027] image 3 The HER performance diagram of the CoO@CNTF carbonization product was prepared for Example 1. The current density is 10mA / cm 2 The overpotential is -0.32V.

[0028] Figure 4 The OER performance diagram of the CoO@CNTF c...

Embodiment 2

[0031] The concentration of cobalt nitrate hexahydrate is 0.2mol / L, and other conditions are the same as in Example 1.

Embodiment 3

[0033] The concentration of cobalt nitrate hexahydrate is 0.8mol / L, and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com