Three-degree-of-freedom magnetic suspension switch reluctance integrated motor

A switched reluctance, integrated motor technology, used in motors, electric components, electric vehicles, etc., can solve the problems of increasing the axial length of the motor system, unfavorable motor ultra-high-speed and high-power operation, and decreasing critical speed and power density. Achieve the effect of large suspension force/suspended current ratio, reduced suspension power consumption, and flexible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

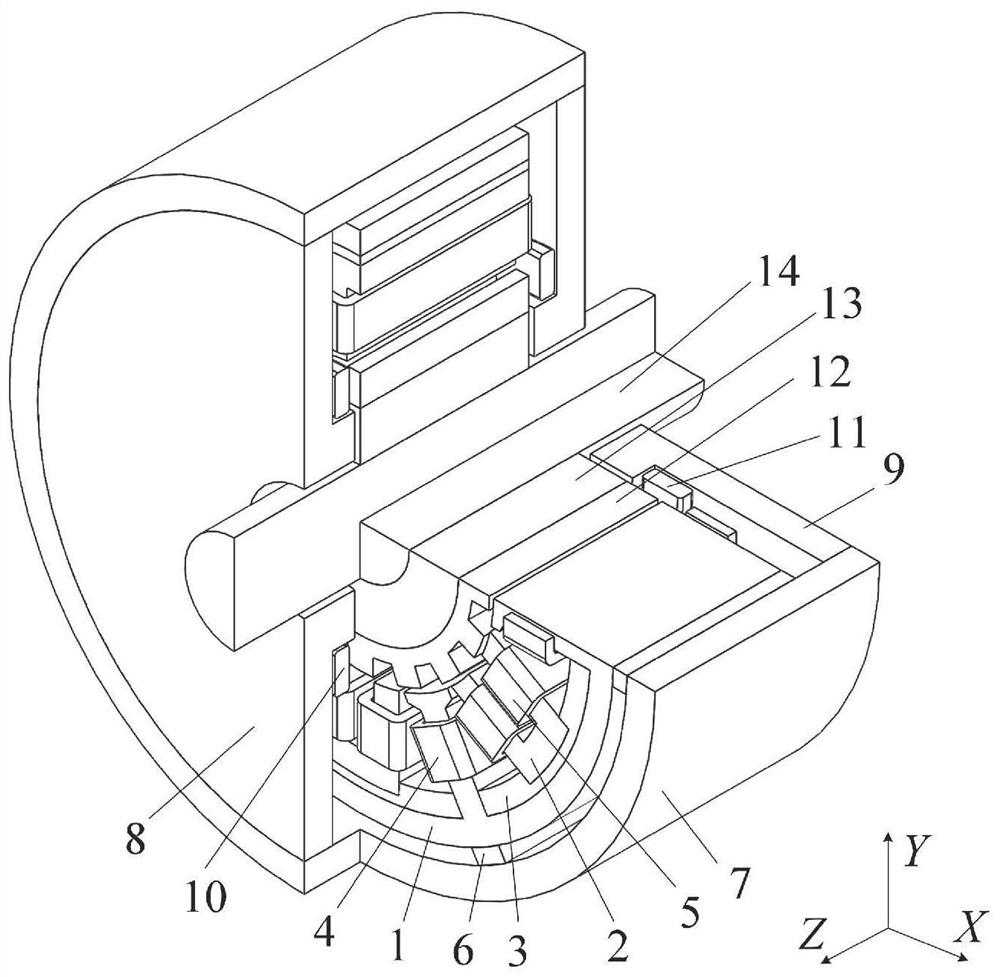

[0047] The technical scheme of a three-degree-of-freedom magnetic levitation switched reluctance integrated motor of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0048] Such as figure 1 As shown, it is a three-dimensional structural schematic diagram of Embodiment 1 of the present invention, wherein, 1 is a radial force stator, 2 is a torque stator, 3 is a non-magnetic support frame, 4 is a radial levitation coil, 5 is a torque coil, 6 7 is the stator annular magnetic yoke, 8 is the axial force stator Ⅰ, 9 is the axial force stator Ⅱ, 10 is the axial suspension coil Ⅰ, 11 is the axial suspension coil Ⅱ, 12 is the rotor, 13 is In the ring-shaped magnetic yoke of the rotor, 14 is the rotating shaft, and X, Y, and Z are the three coordinate axes of the Cartesian coordinate system respectively.

[0049] The three-degree-of-freedom magnetic levitation switched reluctance integrated motor includes a radial force stator, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com