Hydrodealkylation catalyst and preparation method thereof

A hydrodealkylation and catalyst technology, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of little research on transition metal sulfides, and achieve high dealkylation activity and BTX selection performance, improving accessibility, and shortening the diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

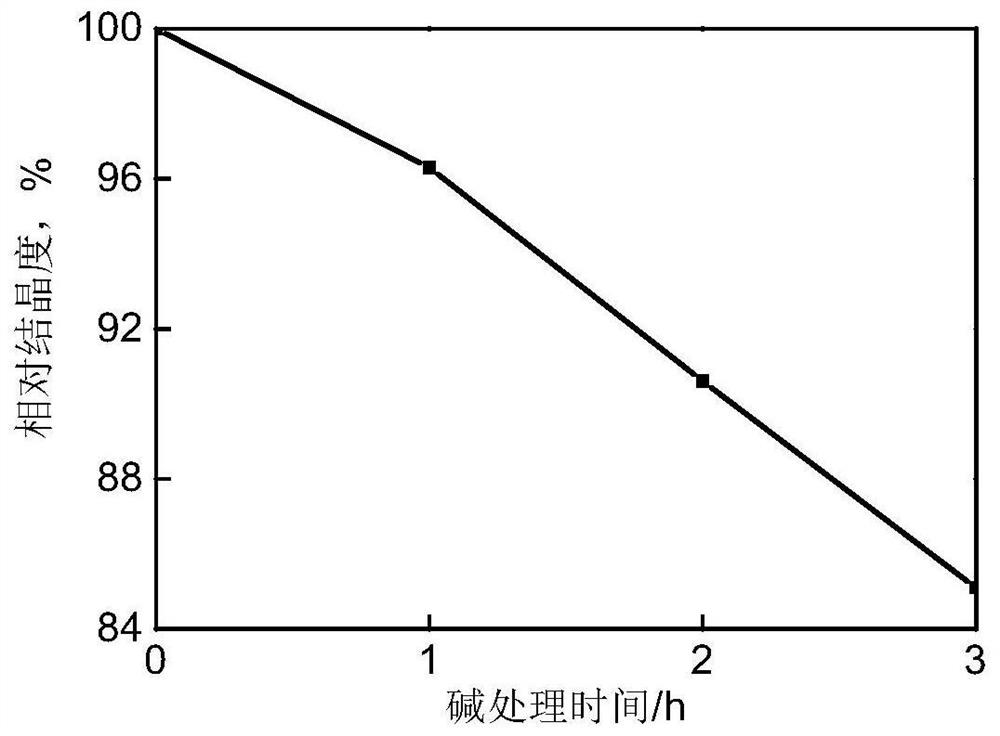

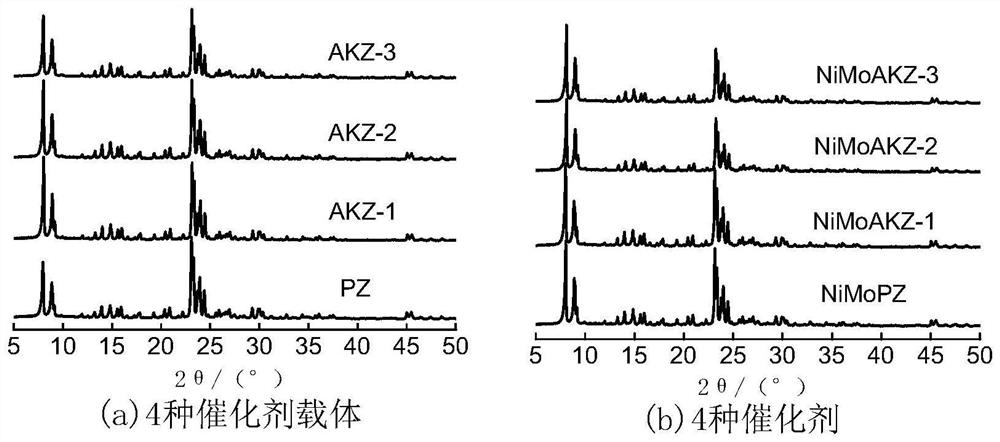

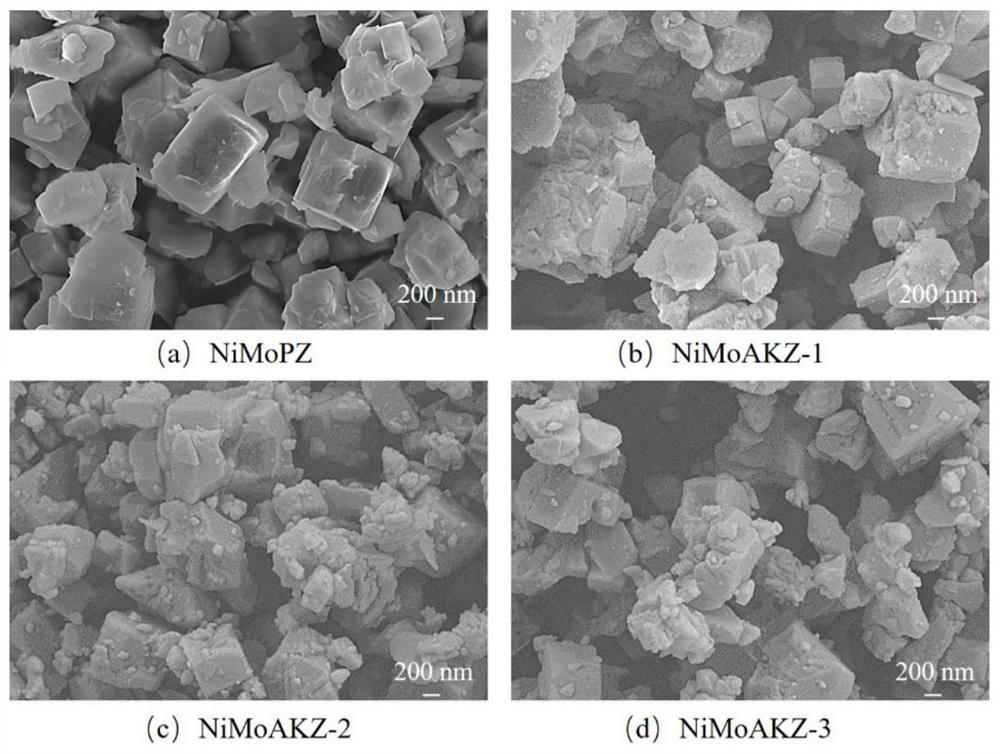

[0026] Alkali treatment: put HZSM-5 in 0.2mol / L NaOH aqueous solution at a liquid-solid ratio of 30mL / g, and stir at 65°C for 1h. Filter, wash until neutral, and dry at 120°C for 4 hours to obtain an alkali-treated sample. Ammonium exchange: put the alkali-treated sample in a 1mol / L ammonium chloride solution at a solid-to-liquid ratio of 10ml / g, stir at 70°C for 4h, filter and wash the product, dry at 120°C for 4h, and roast at 550°C for 4h. Repeat the ammonium exchange step once to obtain micro-mesoporous ZSM-5, press the micro-mesoporous ZMS-5 into tablets, and sieve to obtain 20-40 mesh particles, which are used as catalyst carrier AKZ-1.

[0027] Contains 1.4g MoO in 16mL 3 The ammonium molybdate solution was used as the impregnating solution, and 20g of AKZ-1 was impregnated, left at room temperature for 24 hours, dried at 120°C for 4 hours, and calcined at 550°C for 4 hours to obtain Mo / AKZ-1.

[0028] The above Mo / AKZ-1 was impregnated with 16 mL of nickel acetate so...

Embodiment 2

[0030] The preparation method is the same as that of Example 1, except that the alkali treatment time is 2 hours during the alkali treatment. The obtained micro-mesoporous ZSM-5 carrier is marked as AKZ-2, and the catalyst is marked as NiMoAKZ-2. The catalyst contains AKZ-2 92wt%, MoO 3 6.5wt%, NiO 1.5wt%.

Embodiment 3

[0032] The preparation method is the same as that of Example 1, except that the alkali treatment time is 3 hours during the alkali treatment. The obtained micro-mesoporous ZSM-5 carrier is marked as AKZ-3, and the catalyst is marked as NiMoAKZ-3. The catalyst contains AKZ-3 92wt%, MoO 3 6.5wt%, NiO 1.5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com