Electrostatic spraying process

An electrostatic spraying and crafting technology, applied in coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve environmental problems such as coating hardness, failure to reach 2H level, difficulty in meeting green coating requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

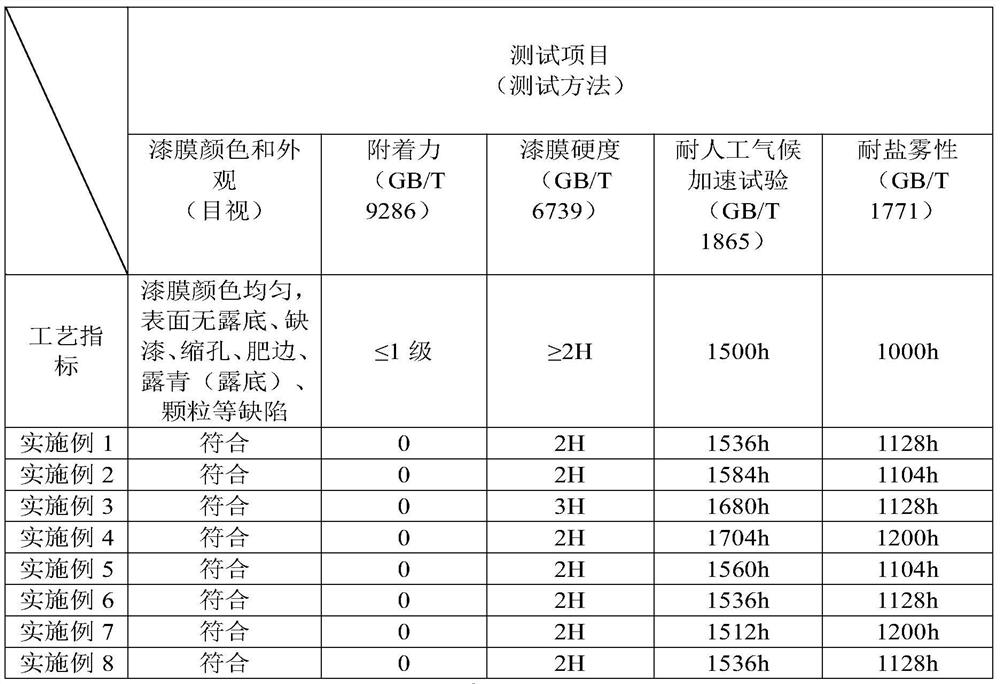

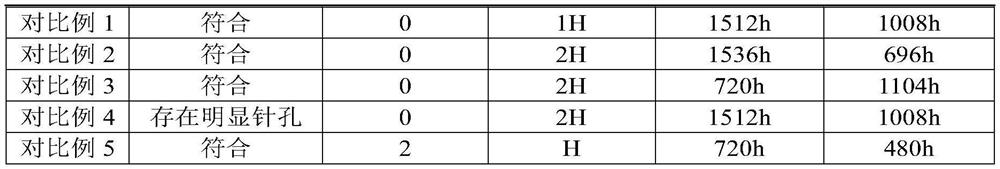

Examples

Embodiment 1

[0033] Embodiment 1 (workpiece is the agricultural machinery product sheet piece that does not have corrosion):

[0034] A kind of electrostatic spraying process, comprises the following steps:

[0035] Step 1, degreasing, degreasing the workpiece;

[0036] Step 2, first-level water washing, washing the degreased workpiece at least twice, including the first pure water washing;

[0037] Step 3, pretreatment, spraying the workpiece with a pretreatment agent;

[0038] Step 4, secondary water washing, the workpiece after spraying is subjected to pure water washing for the second time;

[0039] Step 5, intermediate treatment, dewatering, intermediate drying and first strong cooling treatment on the cleaned workpiece;

[0040] Step 6, spraying the powder coating, spraying the bottom powder coating and the surface layer powder coating successively to the surface of the workpiece after the intermediate treatment;

[0041] Step 7, post-processing, the workpiece after spraying is b...

Embodiment 2

[0056] Embodiment 2 (workpiece is the agricultural machinery product sheet piece that does not have corrosion):

[0057] Different from Example 1, in the step 1, the operating temperature of the alkaline degreasing liquid is 40°C, in the step 5, the drying temperature of the intermediate drying is 90°C, and the drying The time is 12 minutes. In the step 6, the thicknesses of the primer powder coating and the surface coating are 60 μm and 62 μm respectively.

Embodiment 3

[0058] Embodiment 3 (workpiece is the thin plate of agricultural machinery product that corrodes):

[0059] The difference from Example 1 is that in the step 2, the first tap water washing, rust removal cleaning, second tap water washing and first pure water washing are carried out in sequence, and the rust removal cleaning adopts a pH value of 6.5-7.5 neutral cleaning solution to spray and clean the workpiece. The cleaning temperature is 50°C and the spraying time is 3 minutes to remove the rust on the surface of the workpiece. The components of the neutral cleaning solution include surfactants, accelerators and corrosion inhibitors. agent;

[0060] The second tap water washing is to use tap water to spray and clean the workpiece after derusting and cleaning, so as to remove the residual neutral cleaning solution on the surface of the workpiece;

[0061] In said step 3, the spray time is 3min;

[0062] In the step 5, the drying temperature of the intermediate drying is 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com