Micron zero-valent iron-loaded biochar for removing hexavalent chromium, and preparation method and application thereof

A technology of biochar and zero-valent iron, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of complex preparation conditions and high cost, and achieve the effect of simple process, low cost and stable source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

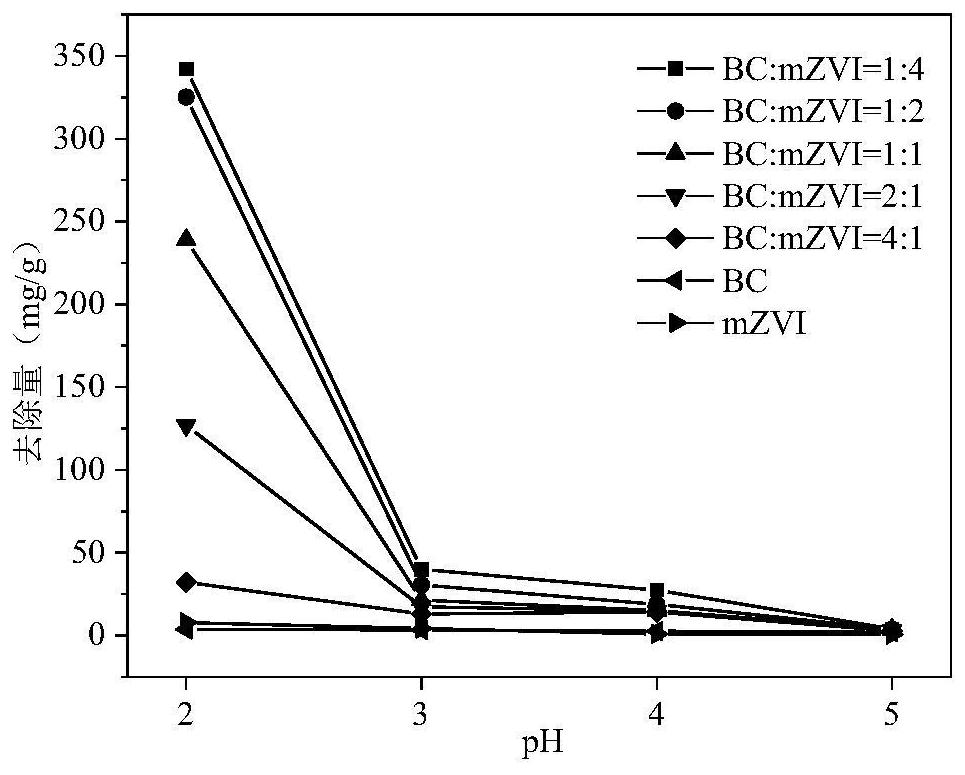

[0019] Micron-loaded zero-valent iron biochar material: wash rice straw with deionized water, dry it in an oven at 90°C for 12 hours, cut it into pieces with a diameter of 1-2 mm, grind and pass through a 100-mesh sieve to obtain rice straw powder, Put 3g of rice straw powder into a tube furnace, heat up to 500°C at a rate of 10°C / min under vacuum, and continue to calcine at this temperature for two hours, and then cool to room temperature to obtain rice straw biochar BC Get 2gBC and 8g3000 order mZVI to mix and place in the stainless steel vacuum ball mill jar, add 500g stainless steel balls in the ball mill jar simultaneously, the mass ratio that diameter is 15mm, 5mm, 3mm stainless steel ball is 2:5:3. The ball mill jar was fixed with a cover, and sealed after evacuating for 30 minutes. The ball mill jar was fixed in a ball mill, the rotation speed was set at 400 rpm / min, and the ball milling time was 1.5 h to obtain mZVI-BC-1.

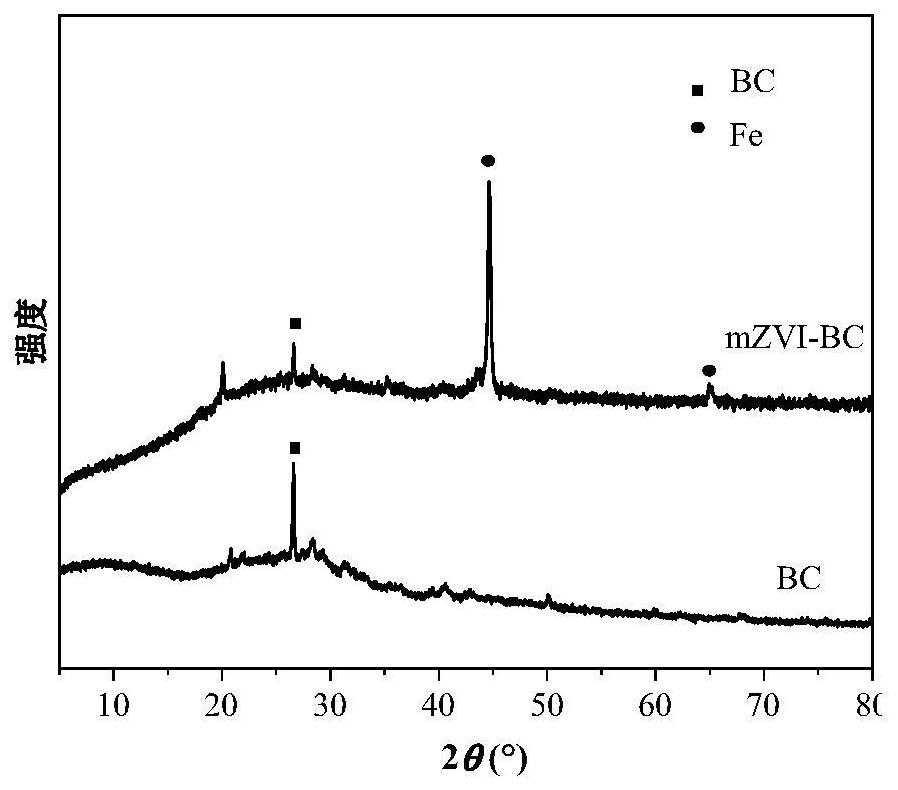

[0020] The XRD analysis results of mZVI-BC ...

Embodiment 2

[0022] Micron-loaded zero-valent iron biochar material: wash rice straw with deionized water, dry it in an oven at 90°C for 12 hours, cut it into pieces with a diameter of 1-2 mm, grind and pass through a 100-mesh sieve to obtain rice straw powder, Put 3g of rice straw powder into a tube furnace, heat up to 500°C at a rate of 10°C / min under vacuum, and continue to calcine at this temperature for two hours, and then cool to room temperature to obtain rice straw biochar BC Get 4gBC and 6g3000 order mZVI to mix and place in the stainless steel vacuum ball mill jar, add 500g stainless steel balls in the ball mill jar simultaneously, the mass ratio that diameter is 15mm, 5mm, 3mm stainless steel ball is 2:5:3. The ball mill jar was fixed with a cover, and sealed after evacuating for 30 minutes. The ball mill jar was fixed in a ball mill, the rotation speed was set at 400 rpm / min, and the ball milling time was 1.5 h to obtain mZVI-BC-2.

Embodiment 3

[0024] Micron-loaded zero-valent iron biochar material: wash rice straw with deionized water, dry it in an oven at 90°C for 12 hours, cut it into pieces with a diameter of 1-2mm, grind and pass through a 100-mesh sieve to obtain rice straw powder, Put 3g of rice straw powder into a tube furnace, heat up to 500°C at a rate of 10°C / min under vacuum, and continue to calcine at this temperature for two hours, and then cool to room temperature to obtain rice straw biochar BC Get 5gBC and 5g3000 order mZVI to mix and place in the stainless steel vacuum ball mill jar, add 500g stainless steel balls in the ball mill jar simultaneously, the mass ratio that diameter is 15mm, 5mm, 3mm stainless steel ball is 2:5:3. The ball mill jar was fixed with a cover, and sealed after evacuating for 30 minutes. The ball mill jar was fixed in a ball mill, the rotation speed was set at 400 rpm / min, and the ball milling time was 1.5 h to obtain mZVI-BC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com