Positive electrode slurry, positive electrode plate and lithium ion battery

A technology of positive electrode slurry and positive electrode sheet, applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problems of abnormal production, brittle electrode sheet, and electrode sheet winding, etc., and achieve the reduction of burr probability and flexibility The effect of increasing the softening temperature and reducing the embrittlement temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

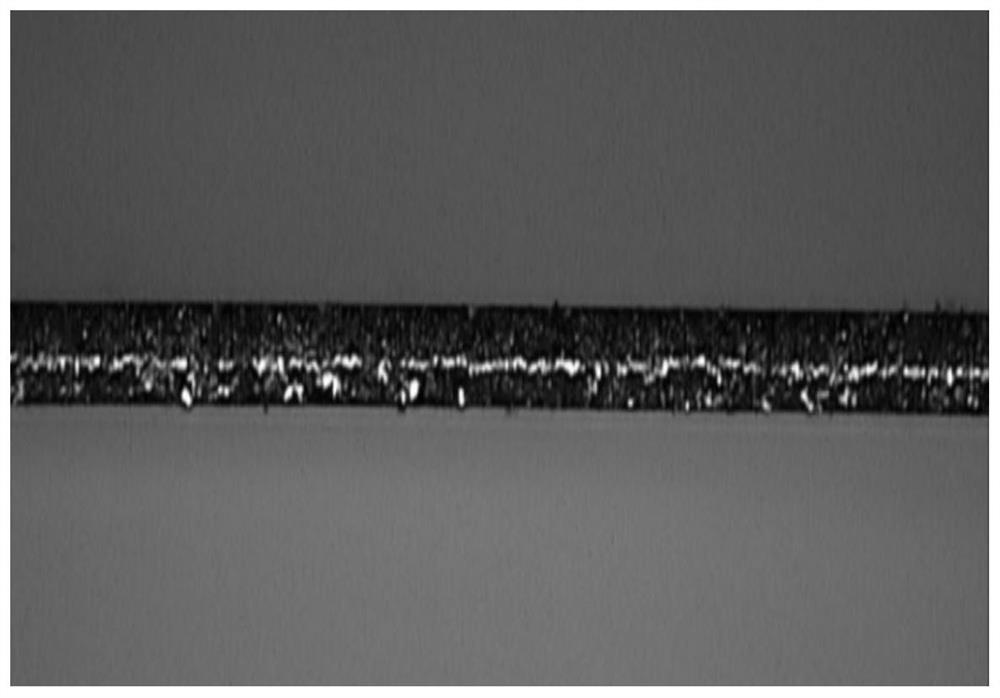

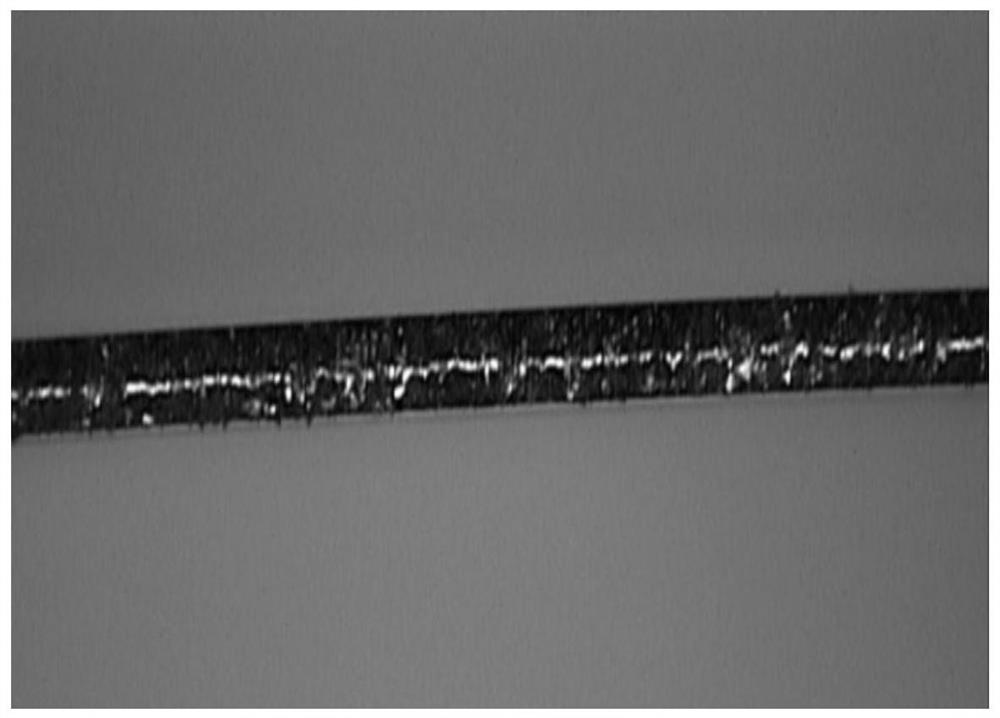

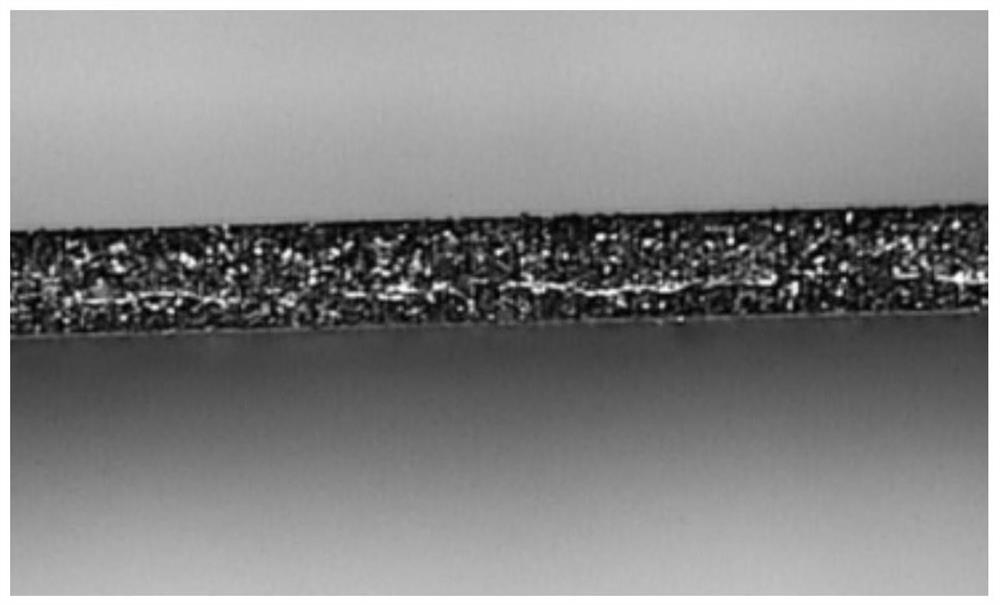

Image

Examples

Embodiment 1

[0050] This embodiment provides a positive electrode slurry, which includes 0.1 kg of PVDF, 0.026 kg of carbon nanotubes, 0.03 kg of conductive carbon black, 5 kg of ternary nickel-cobalt-manganese positive electrode materials, and 0.03 kg of lithium bistrifluoromethanesulfonimide.

[0051] The preparation steps of the positive electrode slurry of the present embodiment include:

[0052] Step S1: dissolving 0.1kg PVDF in the organic solvent N-methylpyrrolidone in a mechanical stirring device to obtain a glue solution, the solid content of the glue solution is 4.35wt%.

[0053] Step S2: Add the dispersion containing 0.026kg of carbon nanotubes and 0.03kg of conductive carbon black to the glue solution in step S1, and stir under a vacuum of -0.095MPa to obtain a uniformly dispersed conductive paste. Among them, the rotation speed of stirring was 4500 rpm, and the revolution speed was 25 rpm.

[0054] Step S3: Add 5 kg of ternary nickel-cobalt-manganese cathode material to the c...

Embodiment 2~ Embodiment 6

[0059] Embodiments 2 to 6 provide a positive electrode slurry and a preparation method thereof. Compared with Example 1, the only difference is that the positive electrode slurry of Examples 2 to 6 has a ternary nickel-cobalt-manganese positive electrode material and a double The amount of lithium trifluoromethanesulfonyl imide is different from Example 1, and its amount is recorded in Table 1.

[0060] Embodiments 2 to 6 also provide a positive electrode sheet and a preparation method thereof. Compared with embodiment 1, the only difference is that the compacted density of the positive electrode sheet in embodiments 2 to 6 is different from that of embodiment 1. , and their compacted densities are recorded in Table 1.

Embodiment 7

[0062] Example 7 provides a positive electrode slurry and a preparation method thereof. Compared with Example 1, the only difference is that lithium bistrifluoromethanesulfonimide is replaced by lithium difluorooxalate borate. In this example, The amount of lithium difluorooxalate borate is the same as the amount of lithium bistrifluoromethanesulfonimide in Example 1.

[0063] Example 7 also provides a positive electrode sheet and a preparation method thereof. Compared with Example 1, the only difference is that this example uses the positive electrode slurry of Example 7 for coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com