Device and method for preparing boiling-resistant old hen powder seasoning for hotpot

A technology for preparing a device and an old hen is applied in the field of seasoning processing, and can solve the problems of slow manual granulation efficiency, abnormal shape of the seasoning, and influence on the cooking resistance time of the seasoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

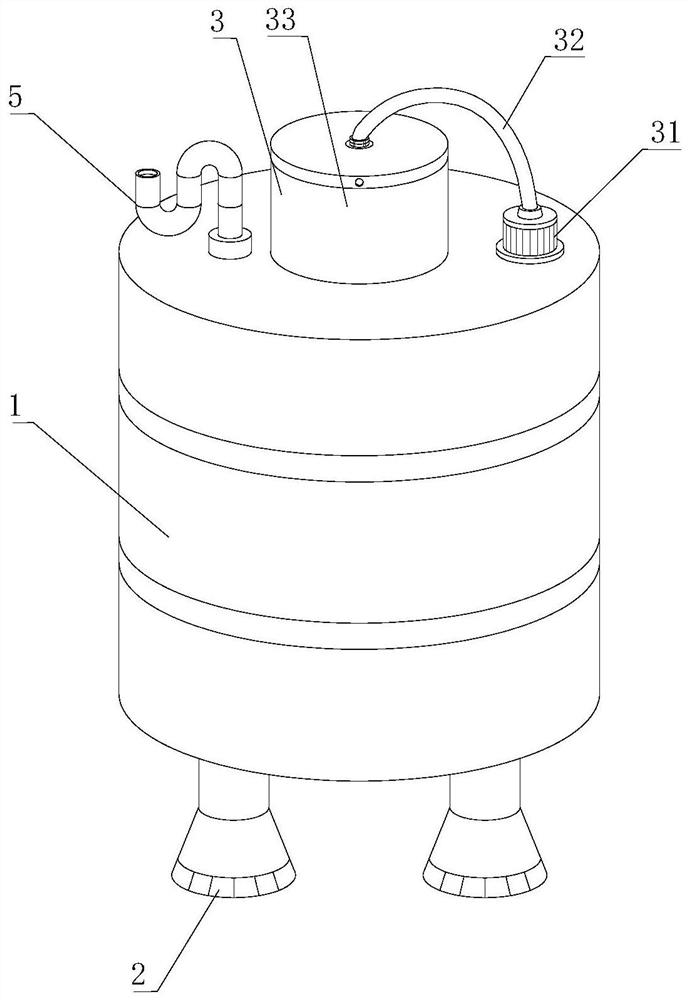

[0047] First aspect, such as Figure 1-11 As shown, the present invention provides a preparation device for cooking-resistant old hen powder seasoning for hot pot, comprising a preparation tank 1, the bottom of the preparation tank 1 is fixedly equipped with support legs 2, and the bottom of the preparation tank 1 is provided with a At the feed port, the top of the preparation tank 1 is provided with a particle preparation mechanism 3 , the inner cavity of the preparation tank 1 is provided with a particle drying mechanism 4 , and the top of the preparation tank 1 is provided with a steam treatment mechanism 5 .

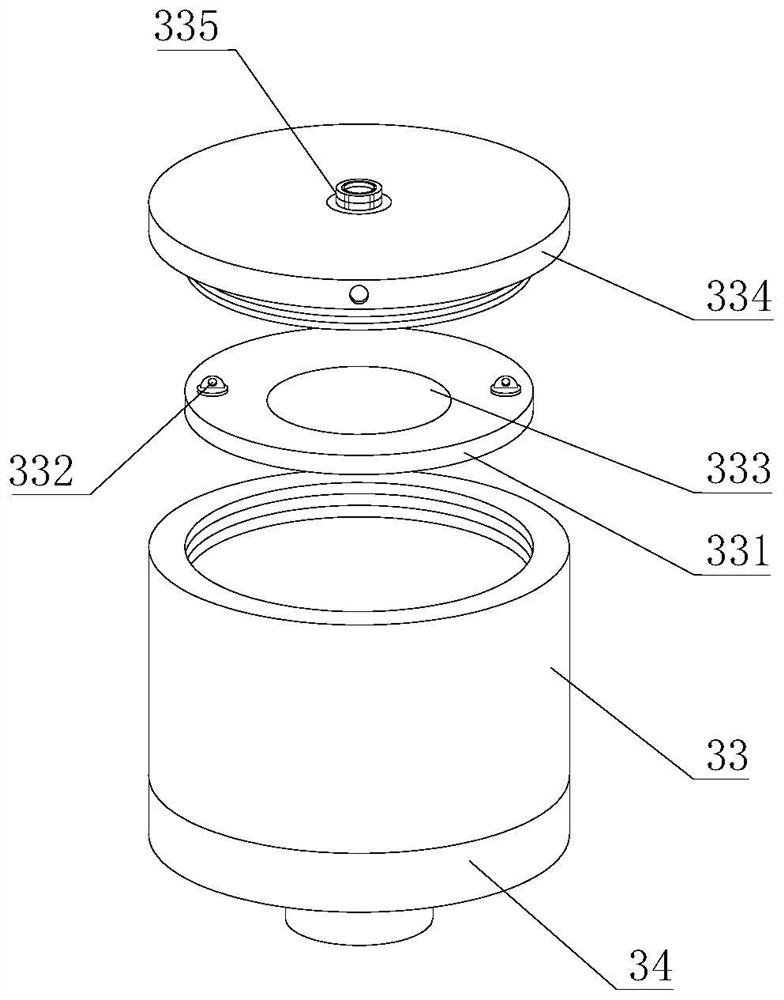

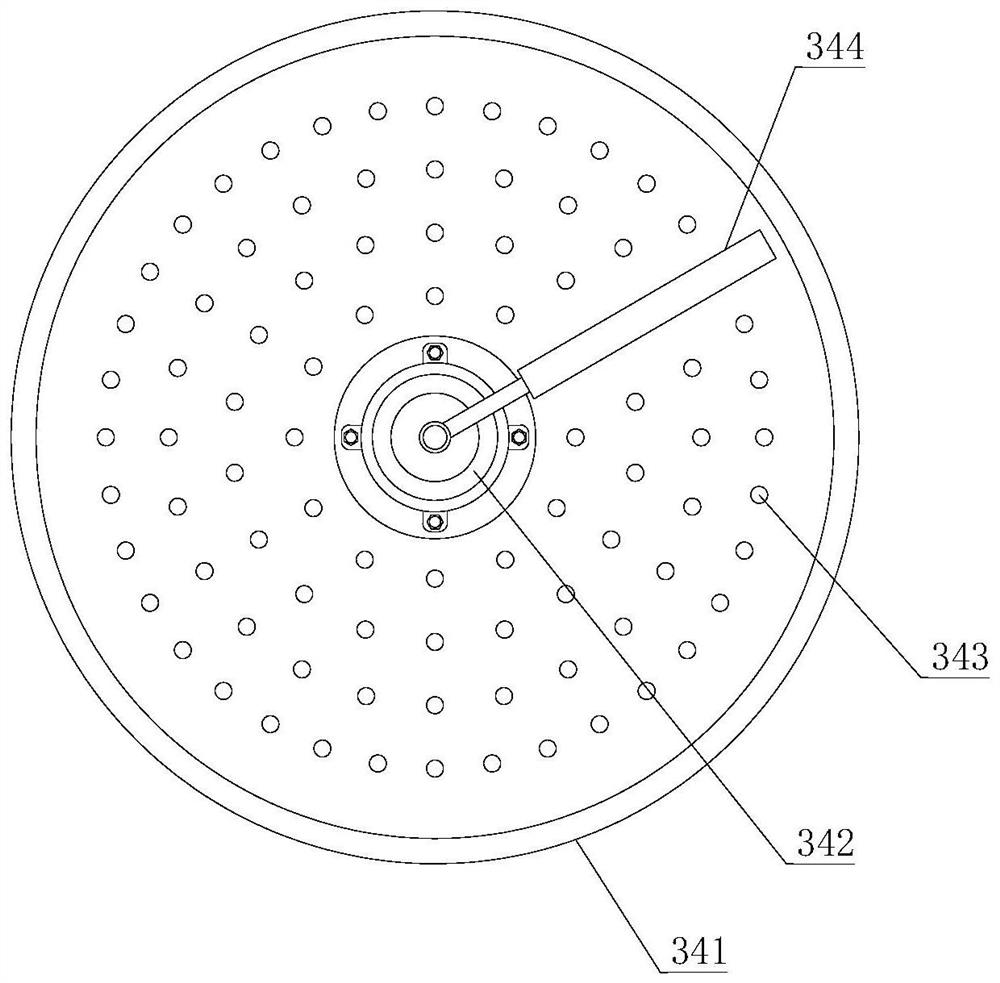

[0048] The particle preparation mechanism 3 includes an air pump body 31 and a raw material push box 33, the air pump body 31 is fixedly installed on the top of the preparation tank 1, controls the air pump body 31, and can deliver to the inner cavity of the raw material push box 33 through a sealed delivery pipe 32 Gas increases the pressure in the inner cavity of t...

Embodiment 2

[0052] Such as Figure 1-11 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a sliding plate 331 is slidably connected to the inner wall of the raw material pushing box 33, and a pulling block 332 is fixedly installed on the top of the sliding plate 331. By setting There is a pulling block 332, which is convenient for users to disassemble the sliding plate 331. By setting the sliding plate 331, inflating the inner cavity of the raw material push box 33 can drive the sliding plate 331 to move, and the prototype material can be moved by the movement of the sliding plate 331. Extruded in a strip shape from the forming hole 343, the top of the sliding plate 331 is provided with a groove 333, the top of the raw material push box 33 is threadedly connected with a sealing cover 334, and the top of the sealing cover 334 is rotatably connected with a rotary connector 335, and the rotating The top of the connecting head 335 is mova...

Embodiment 3

[0054] Such as Figure 1-11 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top of the elastic bracket 44 is embedded with a surrounding frame 45, and by being provided with the surrounding frame 45, the centrifugal force during cutting is avoided from causing seasoning. For the problem of particle splashing, the end of the auxiliary drying rack 42 away from the inner wall of the preparation tank 1 is rotatably connected to a rotating rod 46, and the outer wall of the rotating rod 46 is provided with a pushing mechanism 47. The pushing mechanism 47 includes a receiving rod 471, which is fixedly installed On the outer wall of the rotating rod 46, the front of the receiving rod 471 is provided with a resistance groove 472, the bottom of the receiving rod 471 is fixedly connected with a circular disc 473, and the front of the circular disc 473 is provided with a tapered groove 474, and the air heater body 41 runs It wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com