Method for preparing MAX-phase high-entropy ceramic material

A ceramic material, high-entropy technology, applied in the field of structural ceramic materials, can solve the problems of low hardness and strength, limited application, etc., and achieve the effects of excellent mechanical properties, cost reduction, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

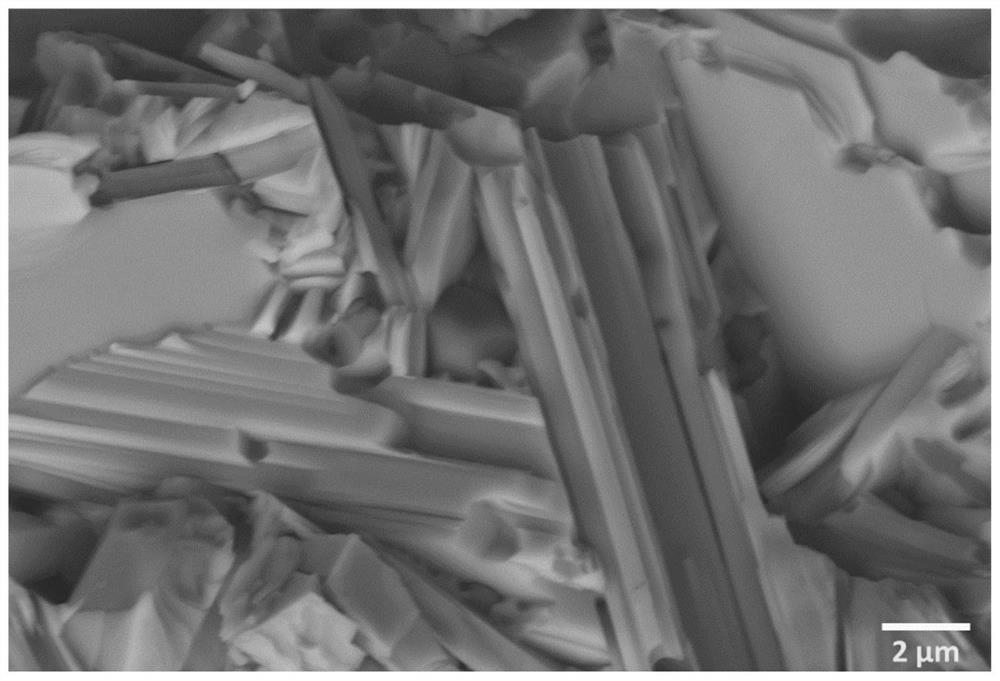

Embodiment 1

[0068] Prepare MAX phase high-entropy ceramic materials according to the following steps

[0069] 1) According to the molar ratio of TiH 2 : V: Nb: TiC: VC: NbC: Al = 1: 1: 1: 1: 1: 1: 3.6 to prepare composite powder.

[0070]2) Pour the compound obtained in step 1) into a ball mill jar, add absolute ethanol as a grinding aid, and place it in a planetary ball mill for ball milling and mixing. The mass ratio of absolute ethanol to composite powder is 2:1.

[0071] The grinding balls are agate balls, Φ10-15mm balls account for 80% of the total balls, Φ5-8mm balls account for 20% of the total balls, the ball-to-material ratio is 6:1, and the milling speed is 360rpm / min, ball milling time is 10h.

[0072] Then, place the mixed slurry obtained after ball milling on a porcelain plate, place it in a vacuum drying oven to dry, set the temperature at 65°C, and evacuate it below 0.1MPa, and evacuate it every 2h. After 8h, turn off the heating device , and the sample was taken out af...

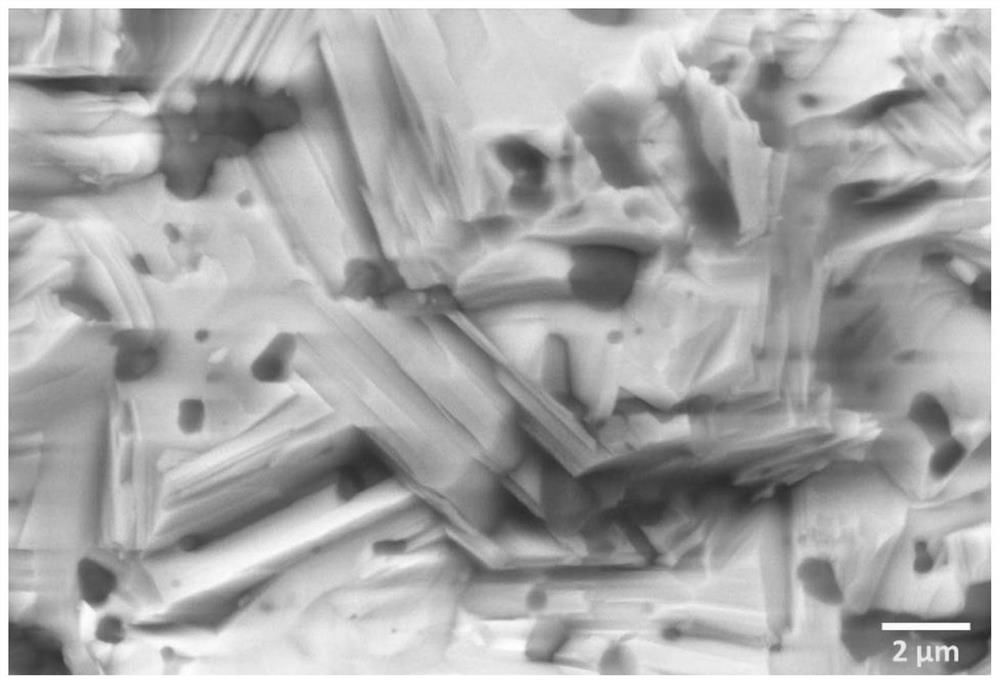

Embodiment 2

[0077] The MAX phase high-entropy ceramic material was prepared according to the following steps:

[0078] 1) According to the molar ratio of TiH 2 : V: Nb: Ta: TiC: VC: NbC: TaC: Al = 1: 1: 1: 1: 1: 1: 1: 1: 4.8 to prepare composite powder.

[0079] 2) Pour the composite powder obtained in step 1) into a ball mill jar, add absolute ethanol as a grinding aid, and place it in a planetary ball mill for ball milling and mixing. The mass ratio of absolute ethanol to the composite powder is 2:1.

[0080] The grinding balls are agate balls, Φ10-15mm balls account for 80% of the total balls, Φ5-8mm balls account for 20% of the total balls, the ball-to-material ratio is 6:1, and the milling speed is 360rpm / min, ball milling time is 10h.

[0081] However, the mixed slurry containing 65% solid phase volume fraction obtained after ball milling was placed in a porcelain plate, dried in a vacuum drying oven, the temperature was set at 65°C, and the vacuum was evacuated to below 0.1MPa, ...

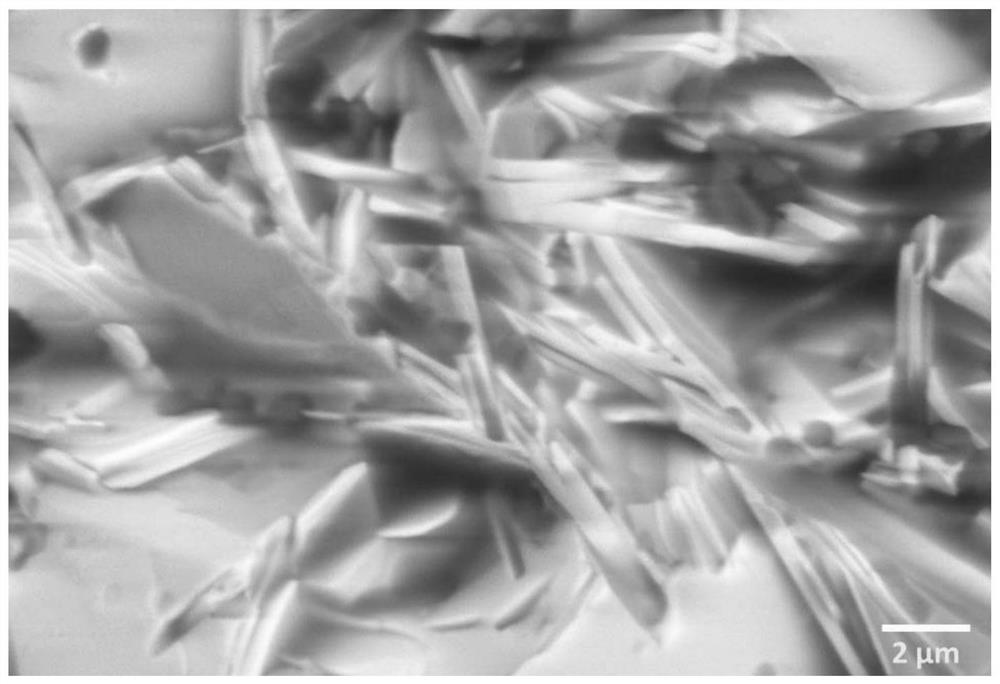

Embodiment 3

[0086] The MAX phase high-entropy ceramic material was prepared according to the following steps:

[0087] 1) According to the molar ratio of TiH 2 :V:Nb:Ta:Cr:TiC:VC:NbC:TaC:Cr 3 C 2 : Al=1:1:1:1:0.5:1:1:1:1:1:0.5:6 to prepare composite powder.

[0088] 2) Pour the composite powder obtained in step 1) into a ball mill jar, add absolute ethanol as a grinding aid, and place it in a high-energy ball mill for ball milling and mixing. The mass ratio of absolute ethanol to the composite powder is 2:1.

[0089] The grinding balls are agate balls, Φ10-15mm balls account for 80% of the total balls, Φ5-8mm balls account for 20% of the total balls, the ball-to-material ratio is 6:1, and the milling speed is 360rpm / min, ball milling time is 10h.

[0090] Then, place the mixed slurry containing 65% solid phase volume fraction obtained after ball milling on a porcelain plate, and dry it in a vacuum drying oven. The temperature is set at 65°C, and the vacuum is evacuated to below 0.1MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com