Fluorescent sensor for detecting gelation degree of Pickering emulsion as well as preparation and application of fluorescent sensor

A fluorescent sensor, emulsion gel technology, applied in the field of fluorescent sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

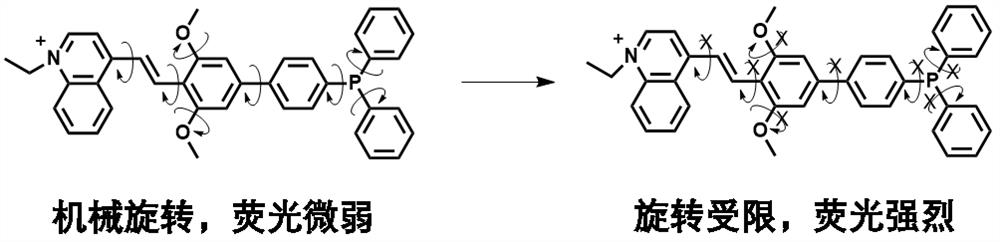

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

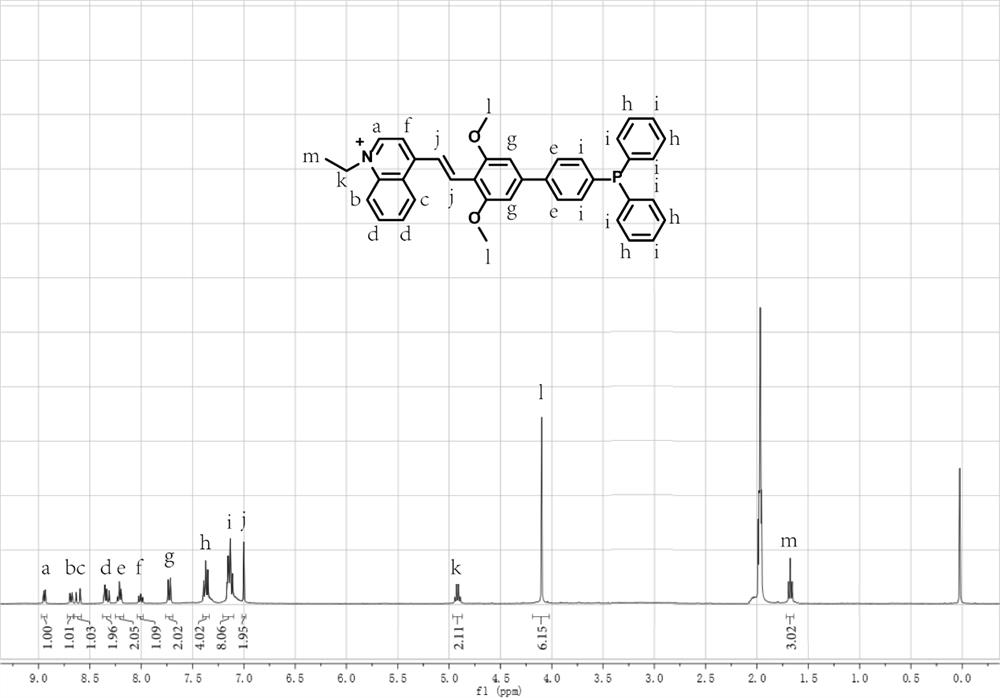

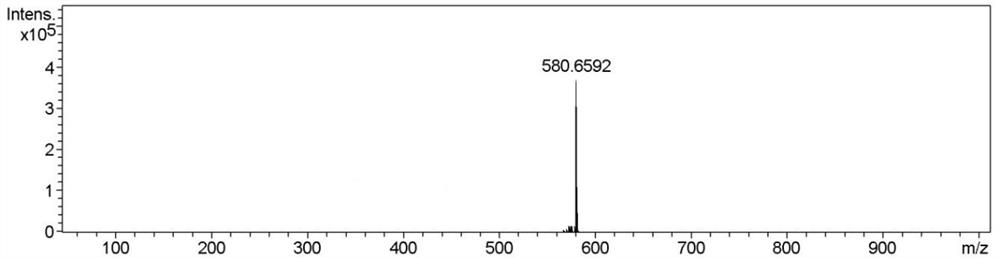

[0047] A preparation method for a fluorescent sensor for Pickering emulsion gelation degree detection, comprising the steps:

[0048] (1) Dissolve 370 mg of 4-(4-bromo-2,6-dimethoxystyrene)-1-ethylquinoline-1-salt in ethanol, stir evenly with ultrasonic, control 4-(4 -Bromo-2,6-dimethoxystyrene)-1-ethylquinoline-1-salt at a concentration of 1 M to obtain solution 1;

[0049] (2) Dissolve 340 mg of (4-bromophenyl)diphenylphosphine in acetonitrile, stir evenly with ultrasonic, control the concentration of (4-bromophenyl)diphenylphosphine to 1 M, and obtain solution 2;

[0050] (3) Mix solution 1 and solution 2, and add 100 mg of calcium carbonate to it, then fill the reaction system with nitrogen, heat the reaction to 81°C, and add 254 mg of pinacol diborate dropwise, After that, 2.25 mg of palladium acetate was added dropwise, and the reaction was stirred for 36 h. After the reaction was completed, the organic solvent was removed, and the crude product was extracted in a separ...

Embodiment 2

[0055] A preparation method for a fluorescent sensor for Pickering emulsion gelation degree detection, comprising the steps:

[0056] (1) Dissolve 370 mg of 4-(4-bromo-2,6-dimethoxystyrene)-1-ethylquinoline-1-salt in ethanol, stir evenly with ultrasonic, control 4-(4 -Bromo-2,6-dimethoxystyrene)-1-ethylquinoline-1-salt at a concentration of 10 M to obtain solution 1;

[0057] (2) Dissolve 850 mg of (4-bromophenyl)diphenylphosphine in acetonitrile, stir evenly, and control the concentration of (4-bromophenyl)diphenylphosphine to 20 M to obtain solution 2;

[0058] (3) Mix solution 1 and solution 2, and add 1000 mg of calcium carbonate to it, then fill the reaction system with nitrogen, heat the reaction to 50°C, and add 635 mg of pinacol diborate dropwise , and then dropwise added 11.25 mg of palladium acetate, and stirred for 18 h. After the reaction was completed, the organic solvent was removed, and the crude product was extracted in a separatory funnel by dichloromethane / w...

Embodiment 3

[0061] A preparation method for a fluorescent sensor for Pickering emulsion gelation degree detection, comprising the steps:

[0062] (1) Dissolve 370 mg of 4-(4-bromo-2,6-dimethoxystyrene)-1-ethylquinoline-1-salt in ethanol, stir evenly with ultrasonic, control 4-(4 -Bromo-2,6-dimethoxystyrene)-1-ethylquinoline-1-salt at a concentration of 20 M to obtain solution 1;

[0063] (2) Dissolve 1700 mg of (4-bromophenyl)diphenylphosphine in acetonitrile, stir evenly with ultrasonic, control the concentration of (4-bromophenyl)diphenylphosphine to 40 M, and obtain solution 2;

[0064] (3) Mix solution 1 and solution 2, and add 2000 mg of calcium carbonate to it, then fill the reaction system with nitrogen, heat the reaction to 20°C, and add 1250 mg of pinacol diborate dropwise , and then dropwise added 22.50mg of palladium acetate, stirred for 1h, after the reaction was finished, after removing the organic solvent, the crude product was extracted in a separatory funnel through a dic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com