A molecular rotor for viscosity detection of fermented milk and its preparation and application

A technology of fermented milk and viscosity, applied in the field of photochemical detection, to achieve the effects of good light stability and chemical structure stability, low raw material price and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

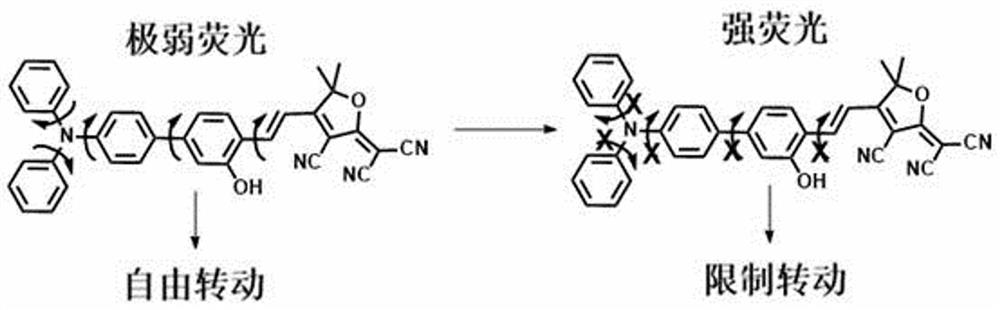

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a molecular rotor for viscosity detection of fermented milk, comprising the steps of:

[0046] (1) Dissolve 365 mg of 4'-(diphenylamino)-3-hydroxy-[1,1'-biphenyl]-4-formaldehyde in ethanol, stir evenly with ultrasonic, control 4'-(diphenylamino )-3-hydroxy-[1,1'-biphenyl]-4-carbaldehyde at a concentration of 0.1 M to obtain solution 1;

[0047] (2) Dissolve 199 mg of 2-(3-cyano-4,5,5-trimethylfuran-2(5H)-ylidene)malononitrile in ethanol, stir evenly with ultrasonic, control 2-( The concentration of 3-cyano-4,5,5-trimethylfuran-2(5H)-ylidene)malononitrile was 0.1 M to obtain solution 2;

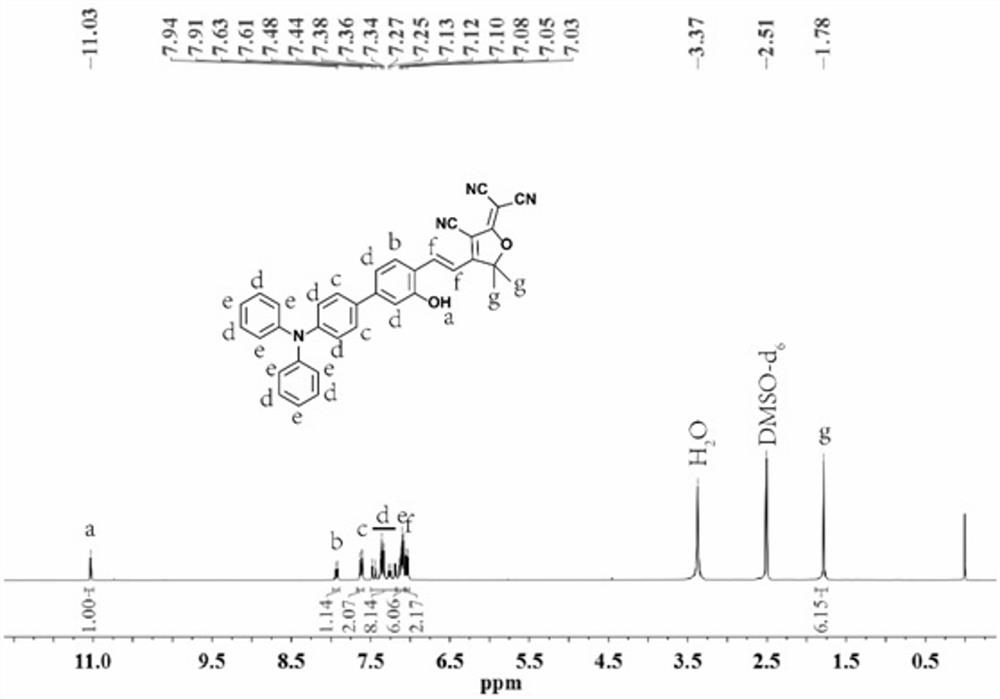

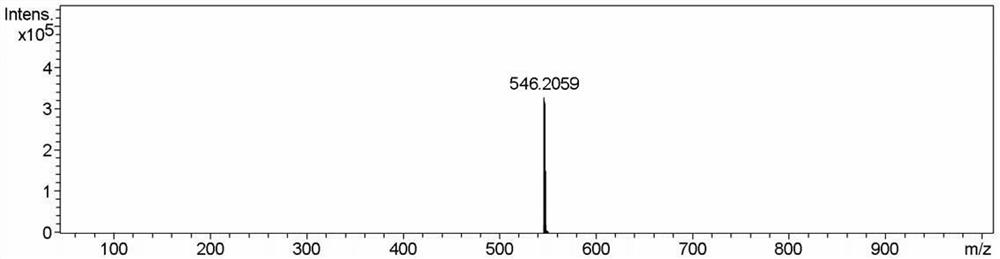

[0048] (3) Mix solution 1 and solution 2, stir evenly, heat to 40 °C, and add 1 mg of triethylamine dropwise. After reacting for 48 hours, remove the organic solvent by distillation under reduced pressure, then use silica gel column separation for rough purification , refined and purified with a neutral alumina chromatographic column, and then dried to obtain 37...

Embodiment 2

[0051] A method for preparing a molecular rotor for viscosity detection of fermented milk, comprising the steps of:

[0052] (1) Dissolve 365 mg of 4'-(diphenylamino)-3-hydroxy-[1,1'-biphenyl]-4-formaldehyde in ethanol, stir evenly with ultrasonic, control 4'-(diphenylamino )-3-hydroxy-[1,1'-biphenyl]-4-carbaldehyde at a concentration of 5 M to obtain solution 1;

[0053] (2) Dissolve 995 mg of 2-(3-cyano-4,5,5-trimethylfuran-2(5H)-ylidene)malononitrile in ethanol, stir evenly with ultrasonic, control 2-( The concentration of 3-cyano-4,5,5-trimethylfuran-2(5H)-ylidene)malononitrile was 25 M to obtain solution 2;

[0054] (3) Mix solution 1 and solution 2, stir evenly, heat to 60 °C, and add 10 mg of triethylamine dropwise. After reacting for 24 hours, remove the organic solvent by distillation under reduced pressure, and then use silica gel column separation for rough purification , refined and purified with a neutral alumina chromatographic column, and then dried to obtain ...

Embodiment 3

[0057] A method for preparing a molecular rotor for viscosity detection of fermented milk, comprising the steps of:

[0058] (1) Dissolve 365 mg of 4'-(diphenylamino)-3-hydroxy-[1,1'-biphenyl]-4-formaldehyde in ethanol, stir evenly with ultrasonic, control 4'-(diphenylamino )-3-hydroxy-[1,1'-biphenyl]-4-carbaldehyde at a concentration of 10 M to obtain solution 1;

[0059] (2) Dissolve 1,990 mg of 2-(3-cyano-4,5,5-trimethylfuran-2(5H)-ylidene)malononitrile in ethanol, stir evenly with ultrasonic, and control 2-( The concentration of 3-cyano-4,5,5-trimethylfuran-2(5H)-ylidene)malononitrile was 50 M to obtain solution 2;

[0060] (3) Mix solution 1 and solution 2, stir evenly, heat to 78 °C, and add 100 mg of triethylamine dropwise. After reacting for 1 hour, remove the organic solvent by distillation under reduced pressure, then use silica gel chromatography column to separate and carry out crude purification , refined and purified with a neutral alumina chromatographic colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com