A method of preparation of titanium pink powder with antibacterial coatings

A technology of antibacterial coatings and titanium dioxide, applied in antifouling/underwater coatings, chemical instruments and methods, fibrous fillers, etc., to overcome zinc-based skin irritation, make up for low antibacterial efficiency, and overcome high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

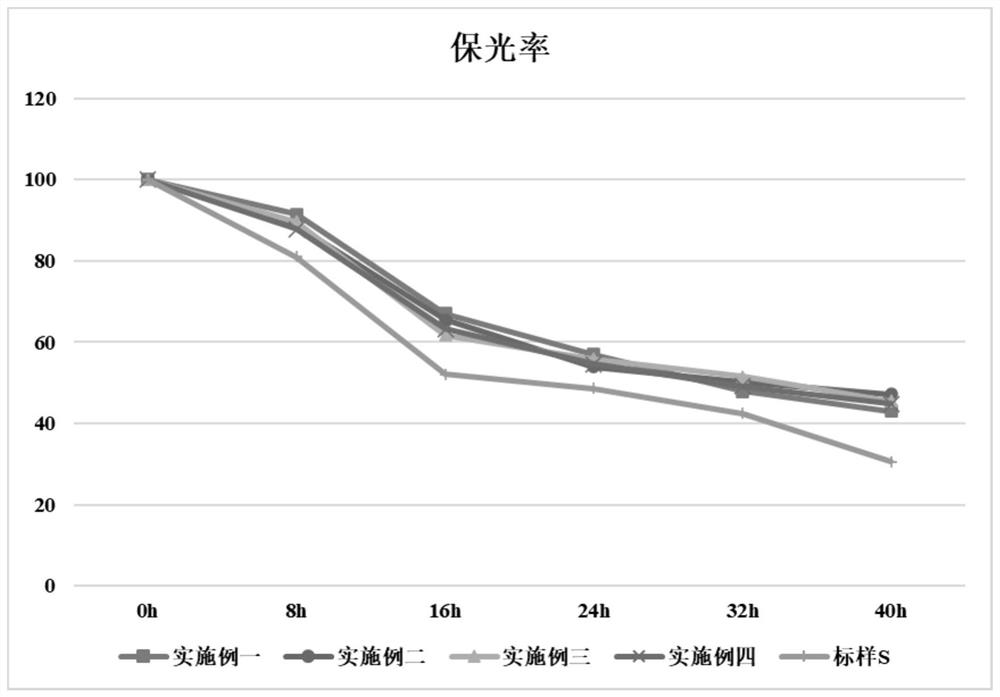

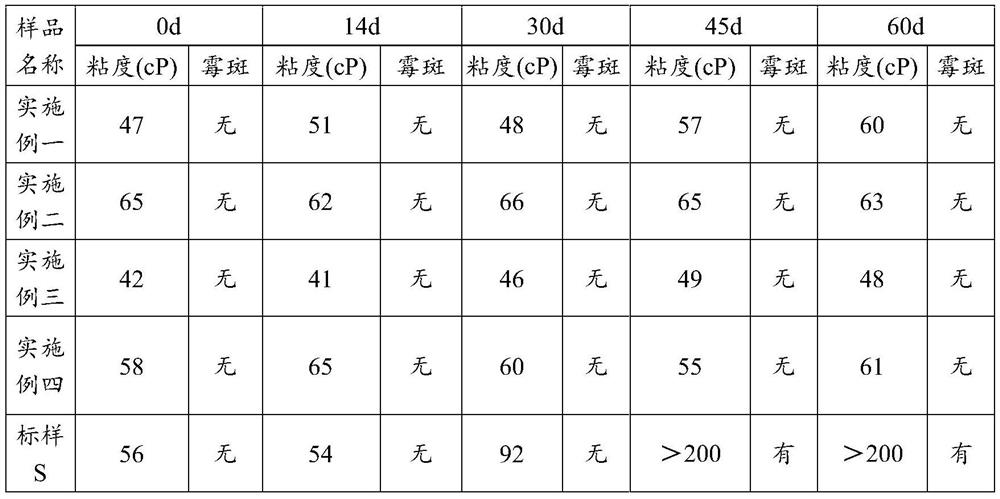

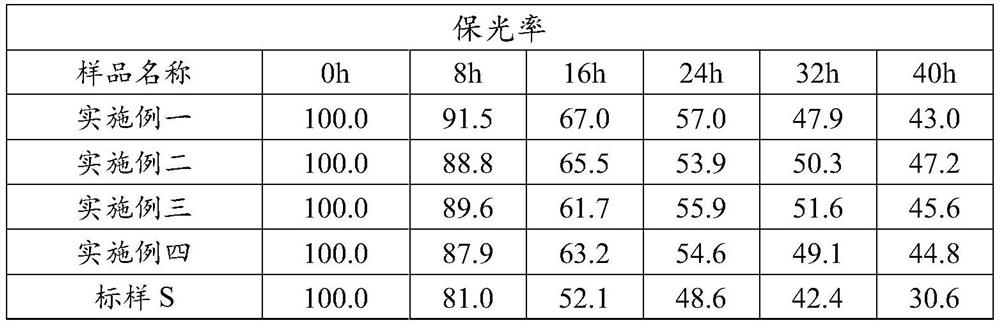

Examples

preparation example Construction

[0025] The preparation method of antibacterial coating titanium dioxide provided by the invention comprises the following steps:

[0026] S1: Prepare titanium dioxide-based material slurry, adjust the pH of the slurry to 7-11, add a dispersant, and homogenize; under the condition of pH 7-11, titanium dioxide particles are most easily dispersed by the dispersant;

[0027] S2: Adjust the pH of the slurry to 7-8, add magnesium silicate, then adjust the pH of the slurry to 2-3, homogenize to form a silicon coating layer, which can block the direct irradiation of ultraviolet rays on titanium dioxide particles, so as to improve the weather resistance of the product sex;

[0028] S3: Adjust the pH of the slurry to 8.5-12, and homogenize to form a magnesium coating layer to improve the antibacterial property of the product;

[0029] S4: Add aluminum source and pH regulator at the same time, homogenize, form aluminum coating layer, improve product dispersibility.

[0030] The present...

Embodiment 1

[0044] After the uncoated sulfuric acid process titanium dioxide is pulverized, wet-milled, sand-milled and diluted, the slurry concentration is 300g / L (based on TiO 2 meter), the pH of the slurry is 8.3, start stirring, and heat up to 70°C; add TiO in the slurry within 10min 2 Sodium hexametaphosphate with a mass of 0.2% was homogenized for 10 minutes; the pH of the slurry was adjusted to 7.8, and TiO in the slurry was added to the slurry 2 3% magnesium silicate by mass; use dilute H within 60 minutes 2 SO 4 Adjust the pH value of the slurry to 2.5, and homogenize for 20 minutes; use dilute NaOH to adjust the pH value of the slurry to 9, and homogenize for 20 minutes; add TiO in the slurry at the same time 2 Mass 2% NaAlO 2 solution and dilute H 2 SO 4 Solution, maintain co-current pH = 8.0, add time 60min, homogenize 30min; use dilute H 2 SO 4 Adjust pH=5.5, adjust for 30 minutes, homogenize for 120 minutes; wash with water, flash evaporate, steam powder to obtain the...

Embodiment 2

[0047] After pulverization, wet grinding, sand grinding and dilution of uncoated sulfuric acid process titanium dioxide, the slurry concentration is 270g / L, the pH of the slurry is 8.3, start stirring, and heat up to 80°C; add 0.2% six Sodium metaphosphate, homogenize for 10 minutes; adjust the pH of the slurry to 8.0, add 5% magnesium silicate to the slurry; use dilute H 2 SO 4 Adjust the pH value of the slurry to 2.3, homogenize for 20 minutes; adjust the pH value of the slurry with dilute NaOH to 9 within 60 minutes, and homogenize for 20 minutes; add 1% NaAlO at the same time 2 solution and dilute H 2 SO 4 Solution, maintain co-current pH = 8.0, add time 60min, homogenize 30min; use dilute H 2 SO 4 Adjust pH=5.5, adjust for 30 minutes, homogenize for 120 minutes; wash with water, flash evaporate, steam powder to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com