Environment-friendly batching tank for biological catalytic fermentation, and use method thereof

A biocatalytic and environment-friendly technology, applied in the direction of biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the inconvenient microbial inactivation cleaning, inconvenient cleaning ingredients tank microbes etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

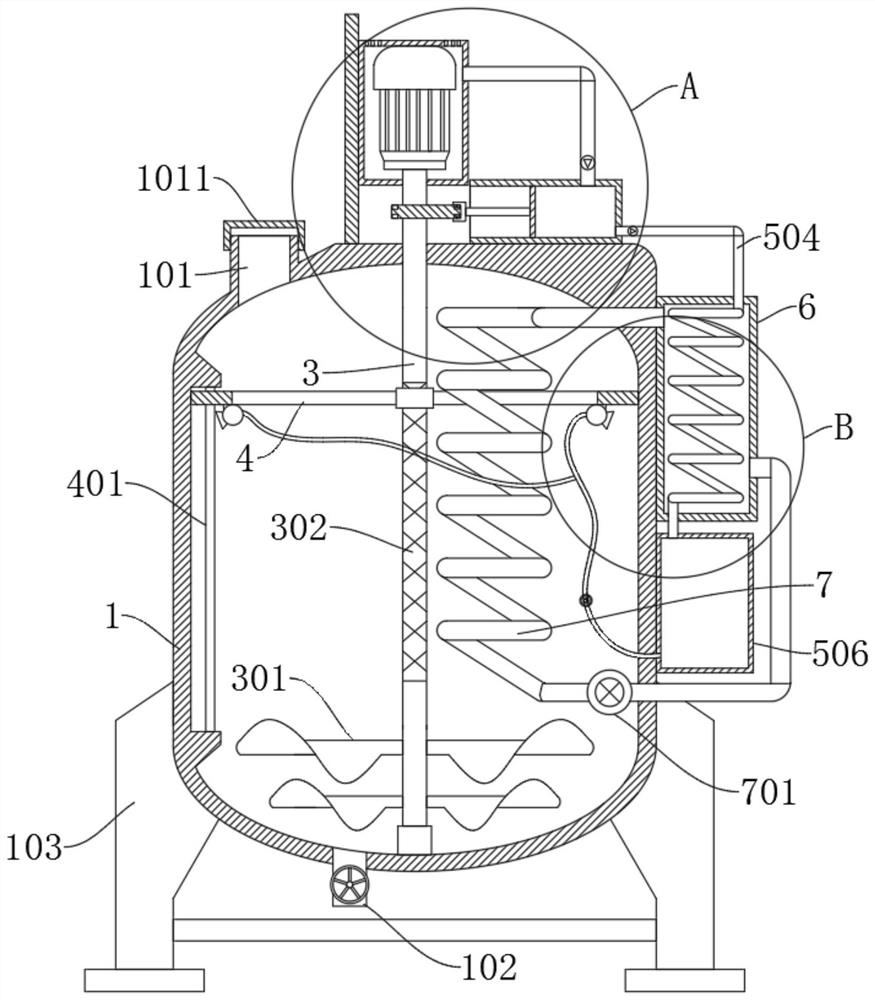

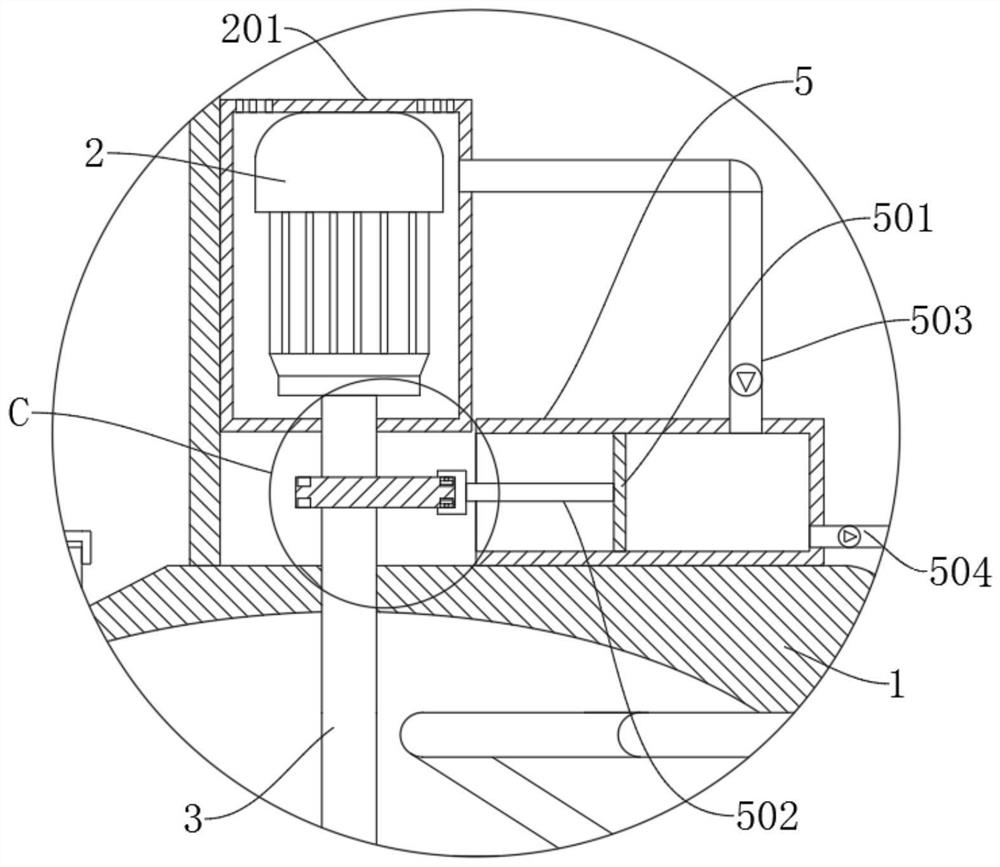

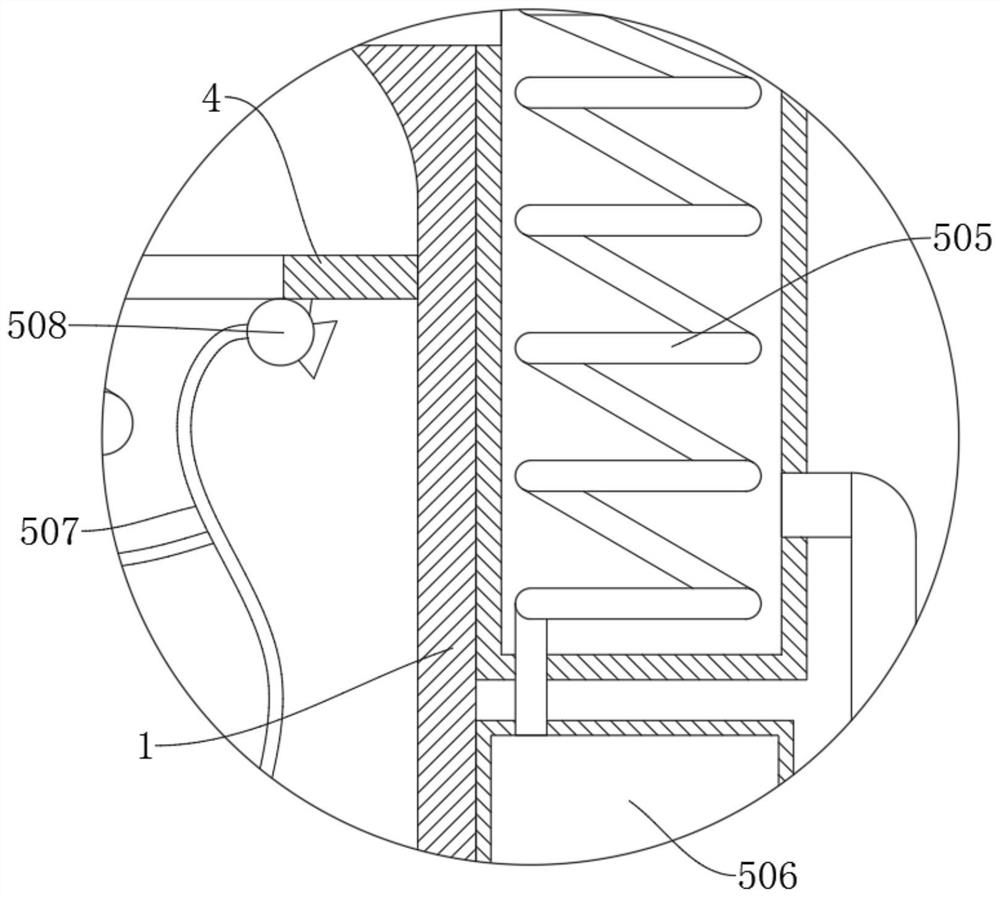

[0041] refer to Figure 1-4 , an environment-friendly batching tank for biocatalytic fermentation, including a tank body 1, a feed pipe 101 and a discharge pipe 102 are arranged on the tank body 1, and a rotating shaft 3 is connected in the tank body 1 in rotation; wherein, the bottom of the rotating shaft 3 The corrugated blade 301 is fixedly connected, and the reciprocating threaded rod 302 is arranged on the rotating shaft 3; the driving part is used to drive the rotating shaft 3 to rotate; the scraper 4 is slidably connected in the tank body 1 and is threadedly connected with the reciprocating threaded rod 302; the heating mechanism, It is the same as heating the reactants in the tank body 1; the heat preservation gas chamber 506 is used to store gas; wherein, an air guide pipe 507 is connected between the heat preservation air chamber 506 and the nozzle 508, and a control valve is arranged on the air guide pipe 507; The exhaust mechanism is used to heat the outside air in...

Embodiment 2

[0044] refer to Figure 1-4 , the environment-friendly batching tank for biocatalytic fermentation is basically the same as in Example 1, furthermore: the drive unit includes a drive motor 2, the output end of the drive motor 2 is fixedly connected to the rotating shaft 3, and the driving motor 2 is conveniently set for the rotating shaft 3 The rotation provides power.

Embodiment 3

[0046] refer to Figure 1-4 , an environment-friendly batching tank for biocatalytic fermentation, which is basically the same as in Example 1, furthermore: the heating mechanism includes a heating box 6, heating oil is housed in the heating box 6, and a second spiral tube 7 is arranged in the tank body 1. Both ends of the two helical tubes 7 take screenshots in the heating box 6, the second helical tube 7 is provided with a pump 701, the heating box 6 heats the heat transfer oil inside, and the pump 701 makes the heat transfer oil heat in the second helical tube 7 and The circulating flow between the tanks 6 heats the reactants in the tank body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com