Martensite heat-resistant steel material and preparation method thereof

A heat-resistant steel and martensite technology, applied in the field of new martensitic heat-resistant steel and its preparation, can solve the problems of insufficient impact toughness cold and hot workability welding performance, and achieve improved impact toughness, hot workability and welding performance. The effect of improvement and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

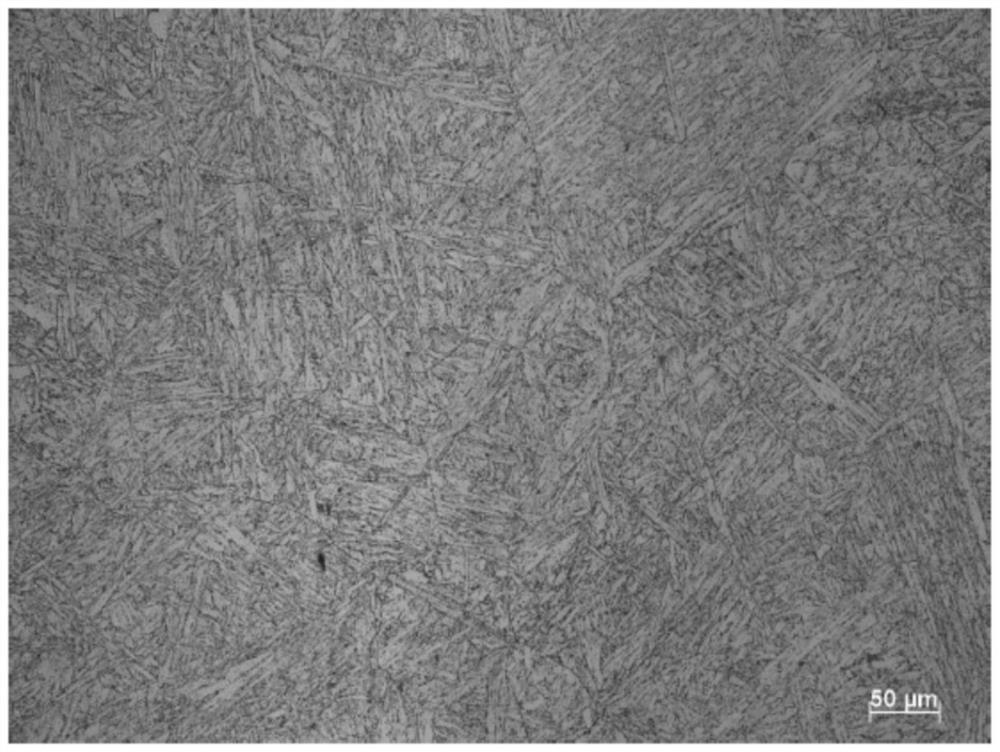

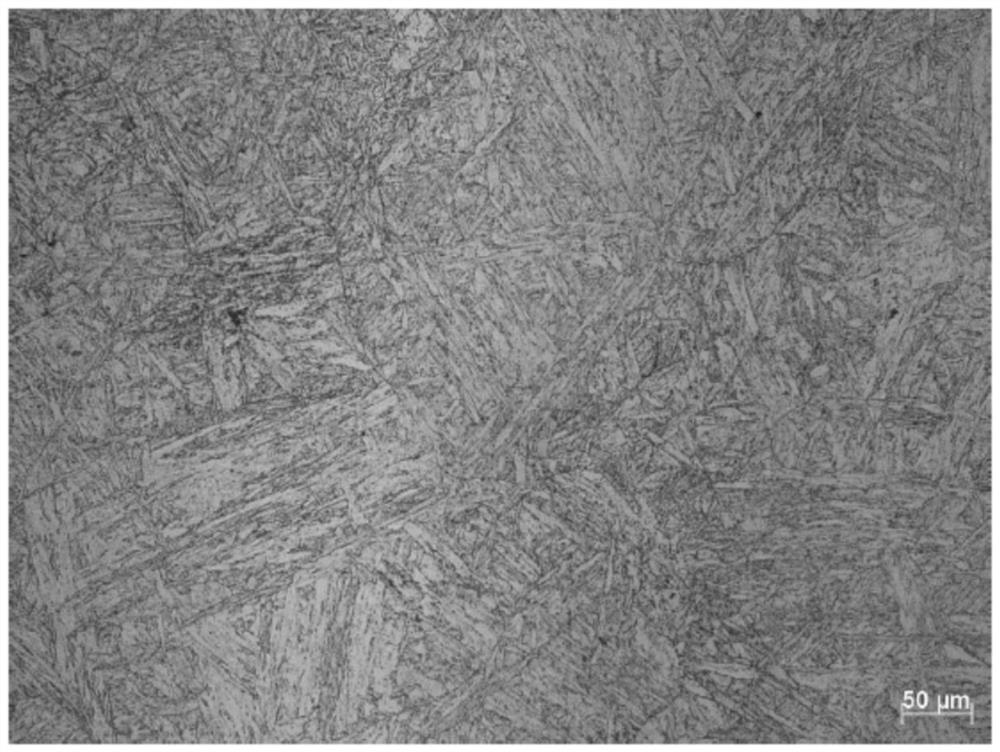

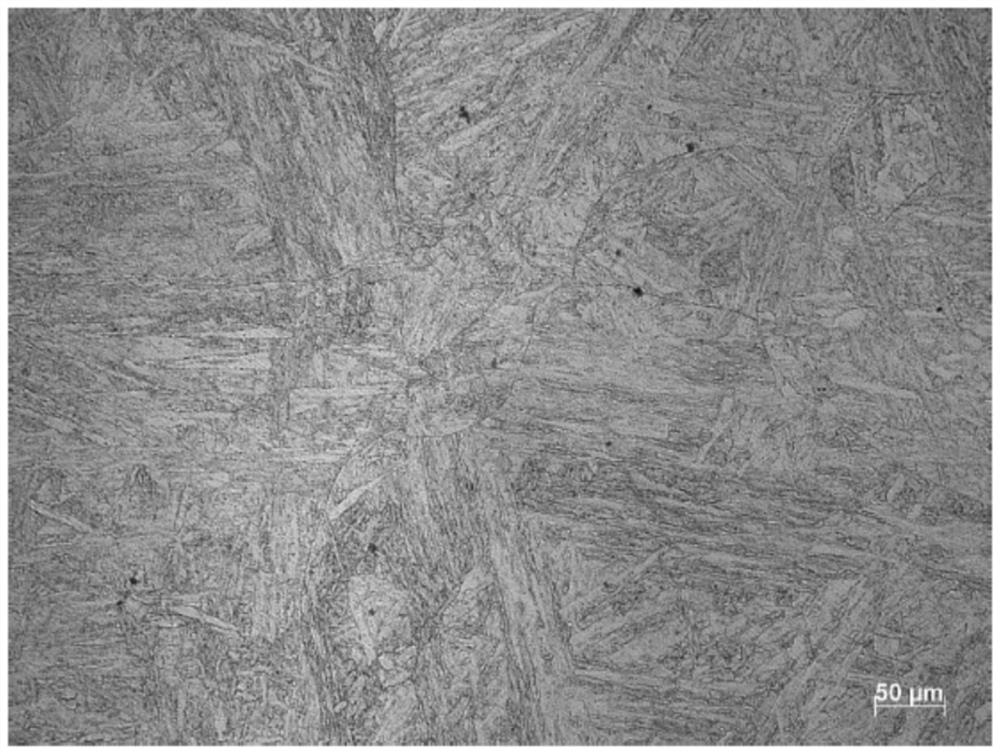

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

[0030] The typical chemical compositions of steel examples (A, B, C) of the present invention and similar steel comparison examples (D, E) are shown in Table 1, wherein Example A is a φ900 bar material trial-produced by Baowu Special Metallurgy, and the quenching and tempering system Insulation at 1050°C for 1h / air cooling + 780°C for 3h / air cooling; Example B is a φ900 rod trial-manufactured by Baowu Special Metallurgy, and the quenching and tempering system is 1060°C for 1h / air cooling +780°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com