Electrochemical surface treatment method for selective laser melting AlSi10Mg alloy heat treatment product

A laser melting and surface treatment technology, which is applied in the direction of additive manufacturing and additive processing, can solve the problems of low precision and large surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

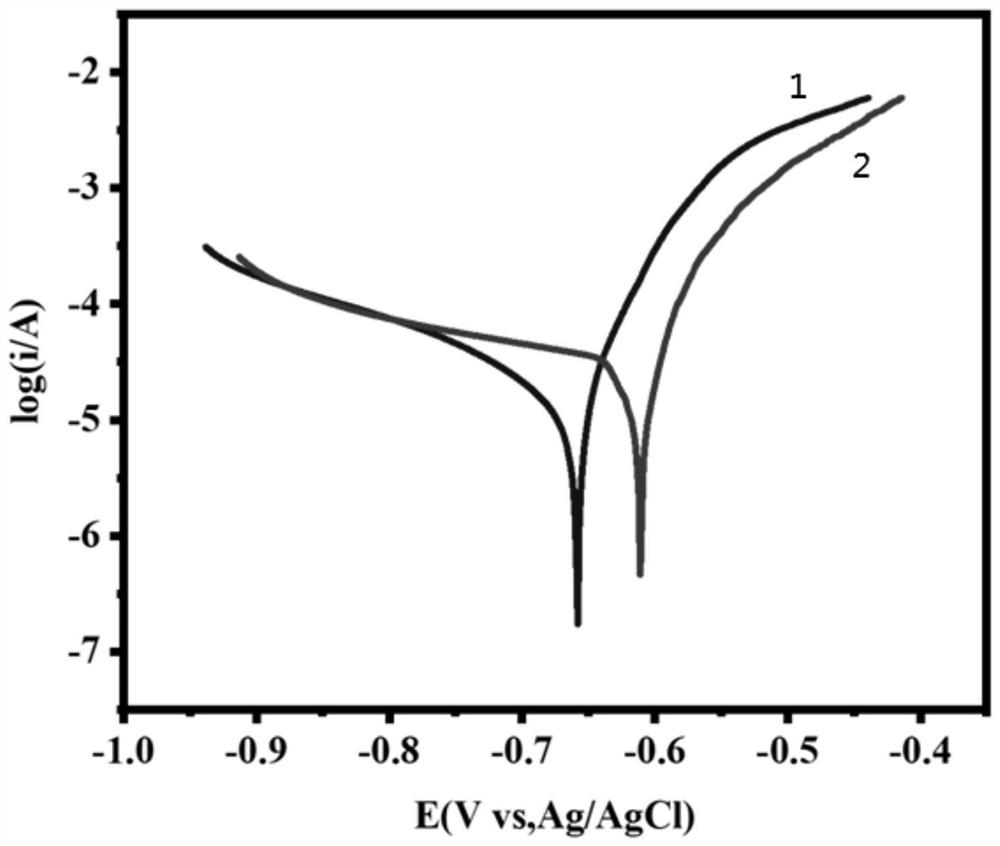

[0031] Embodiment 1: This embodiment is an electrochemical surface treatment method for selective laser melting of AlSi10Mg alloy heat-treated products, characterized in that the method is specifically carried out according to the following steps:

[0032] 1. Use NaOH, EDTA and deionized water to prepare the electrolyte, and control the amount of NaOH to be 60-70g / L and the amount of EDTA to be 15-20g / L;

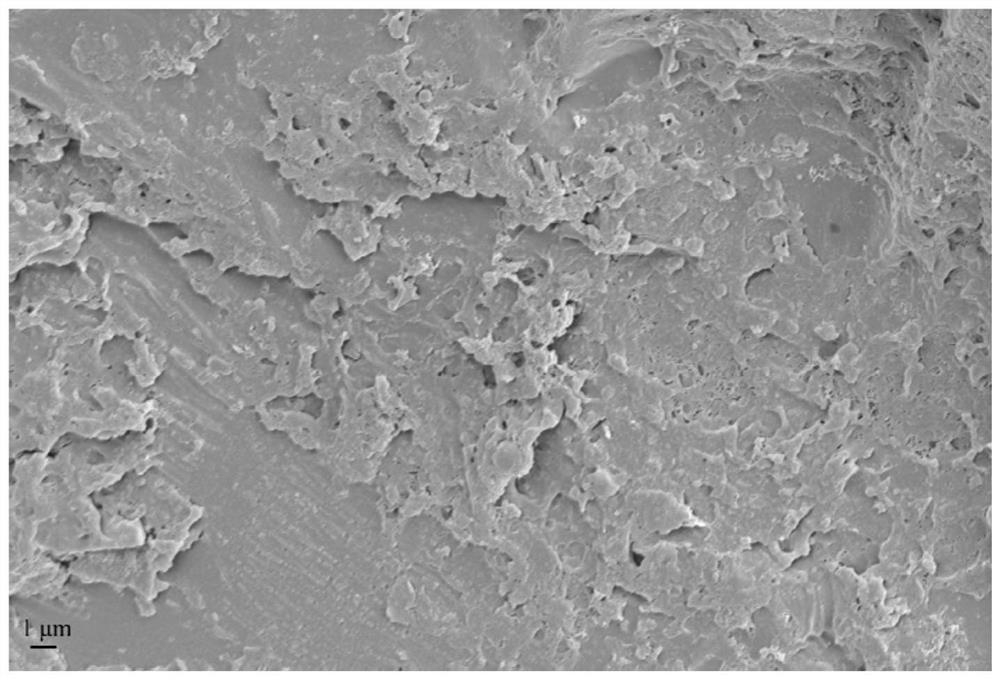

[0033] 2. Grinding the AlSi10Mg alloy, then pickling with pickling solution, rinse with running water immediately after pickling, and dry;

[0034] 3. The AlSi10Mg alloy treated in step 2 is electrochemically polished using a three-electrode system, the platinum sheet is the cathode, the AlSi10Mg alloy is the anode, the Ag / AgCl electrode is the reference electrode, and the electrolyte is prepared in step 1; rinse with running water immediately after polishing;

[0035] Fourth, ultrasonically clean the AlSi10Mg alloy processed in step 3 to complete the electrochemical surface...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the amount of NaOH is controlled to be 60 g / L, and the amount of EDTA is 16.7 g / L. Others are the same as the first embodiment.

specific Embodiment approach 3

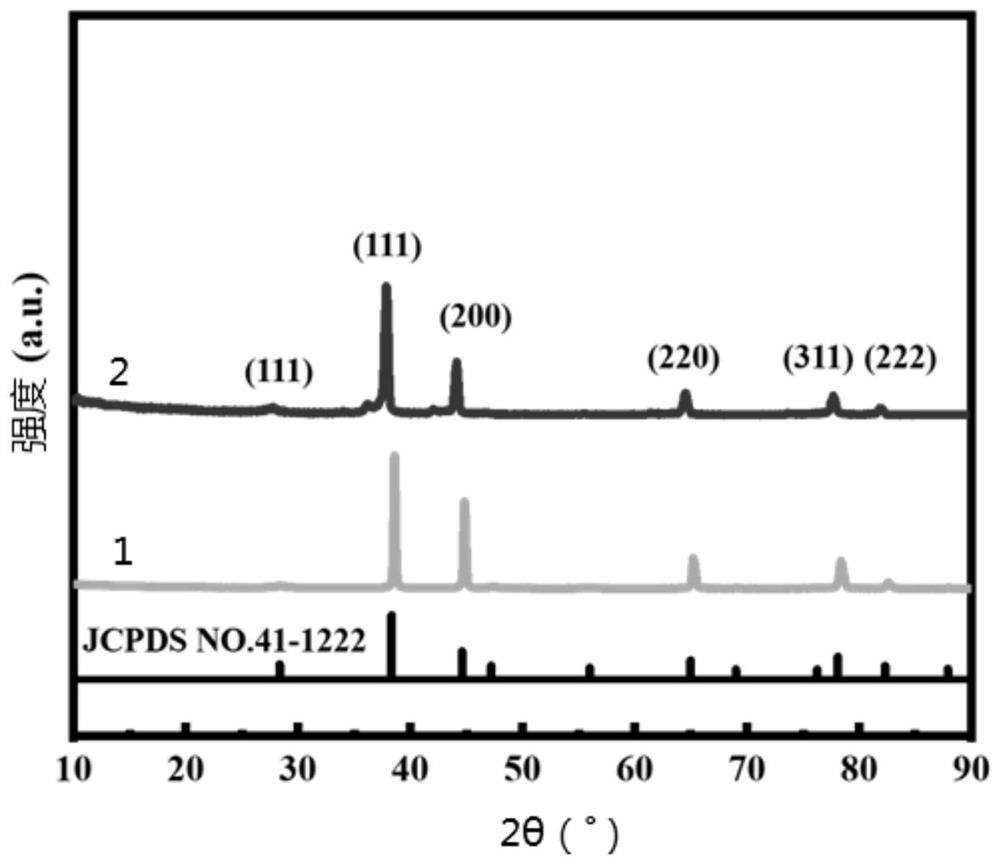

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the mass percentage of elements in the AlSi10Mg alloy described in step 2 is: Si: 10-11%, Mg: 0.2-0.3%, Fe: < 0.05%, Cu: ≤ 0.01%, Ni: ≤ 0.01%, Zn: ≤ 0.01%, Ti: ≤ 0.02% and the balance is aluminum. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com