Method for measuring content of dissolved elements in molten steel

A technology of element content and measurement method, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of unconsidered, different, element content change, etc., to achieve accurate accuracy, prevent loss, and effectively measure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043]Embodiment: (steel sample chemical composition (mass percentage): C 0.998%, Si 0.201%, Mn 0.359% Cr1.44%, S 0.003%, Al 0.0149%, T.Mg 0.0003%, T.Ca 0.0011%, T.O 0.0008%, the rest is Fe, of which the dissolved calcium content is 0.00015%, T.Mg, T.Ca, T.O represent the total magnesium, total calcium and total oxygen content in the steel respectively)

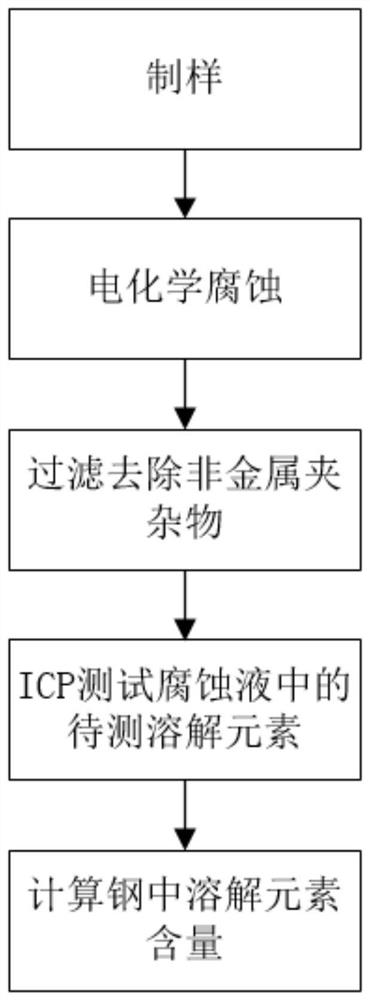

[0044] Such as figure 1 As shown, after sampling molten steel at 1600°C, it was rapidly cooled to room temperature at a rate of 50°C / min, and the steel sample was processed into a round bar with a diameter of 11mm and a height of 110mm, and weighed; with 250ml triethanolamine, glycerol, The methanol solution of tetramethylammonium chloride and acetylacetone is an electrochemical corrosion solution, wherein the mass percentage of triethanolamine is 3%, the mass percentage of glycerin is 3%, and the mass percentage of tetramethylammonium chloride The mass percentage of acetylacetone is 1%; the dissolved calcium in the weighed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com