Roxburgh rose matcha candy as well as preparation method and application thereof

A technology of prickly pear and candy, which is applied to the field of prickly pear and matcha candy and its preparation, can solve the problems of large consumption, loose whole fruit powder tableting, rough and bitter taste, etc., and achieves improved health status, small edible volume and good market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of the Rosa roxburghii matcha candy, which is characterized by comprising the following steps: mixing and molding raw materials including main ingredients and auxiliary materials according to corresponding weight parts to obtain the Rosa roxburghii candy.

[0048] Preferably, the method comprises the steps of:;

[0049] (1) Premixing: dry the roxburghii freeze-dried powder, matcha powder, skimmed milk powder, bulking agent and sweetener after mixing;

[0050] (2) total mixing: add lubricant to step (1) gained material, mix;

[0051] (3) Granulation: the material obtained in step (2) is granulated;

[0052] (4) Packaging: the material obtained in step (3) is compressed into tablets to obtain the Rosa Roxburghii Matcha candy.

[0053] The present invention also provides a kind of food or health food, which is characterized in that it comprises the above-mentioned Rosa roxburghii matcha candy.

[0054] The inventi...

Embodiment 1

[0075] The preparation process of prickly pear matcha candy is as follows:

[0076] Weigh raw materials according to the ratio in column 1 in Table 2: 5 kg of roxburghii freeze-dried powder, 5 kg of matcha powder, 10 kg of skimmed milk powder, 35 kg of white sugar, 40 kg of sorbitol, 0.01 kg of sucralose, 5 kg of starch, magnesium stearate 1.2kg.

[0077] Step 1: Add the roxburghii freeze-dried powder, matcha powder, skimmed milk powder, white sugar, sorbitol, sucralose, and starch into a tank mixer for pre-mixing for 15 minutes.

[0078] Step 2: Dry the material obtained in Step 1 at 40° C. for 120 minutes.

[0079] Step 3: Add the material obtained in Step 2 into a multi-directional motion mixer, add magnesium stearate, and mix for 30 minutes.

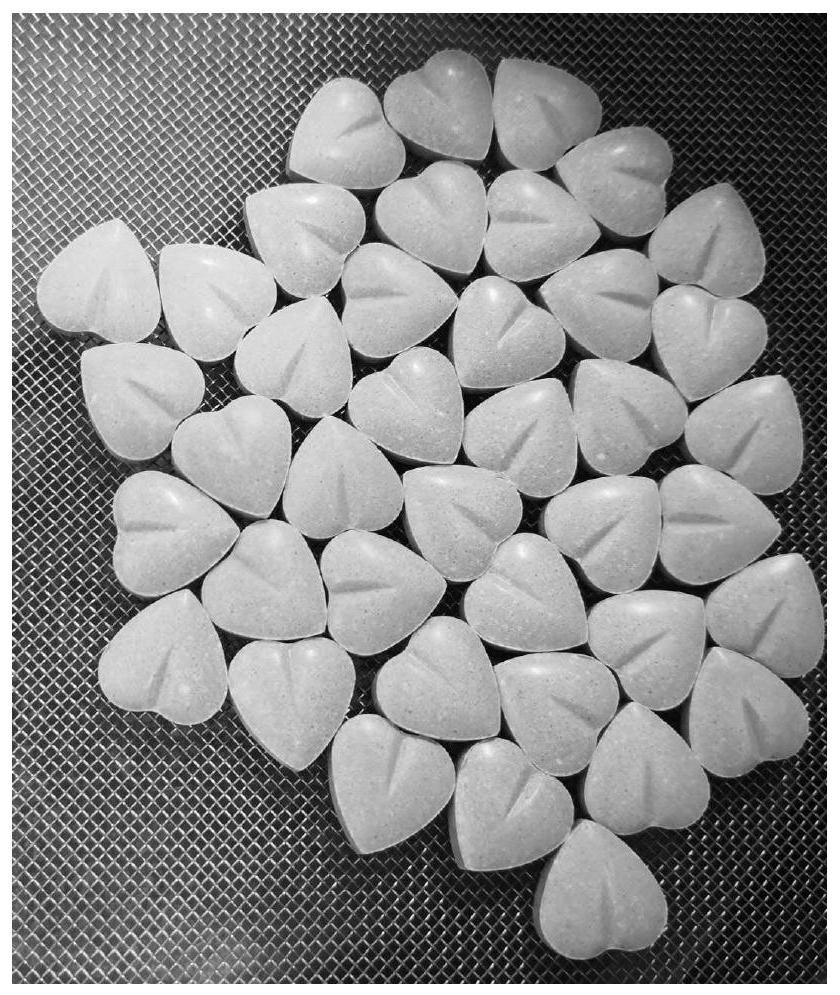

[0080] Step 4: Manually compress the material obtained in step 3 or add it to a rotary tablet press for tableting. The controlled pressure is 35KN, and the tableting amount is 0.91-0.93g / tablet to obtain candy tablets. See figure ...

Embodiment 2

[0082] Weigh raw materials according to the ratio in column 2 in Table 2, roxburghii freeze-dried powder 10kg, matcha powder 5kg, skimmed milk powder 10kg, white sugar 35kg, sorbitol 30kg, sucralose 0.02kg, starch 10kg, magnesium stearate 1.2kg.

[0083] Step 1: Add the roxburghii freeze-dried powder, matcha powder, skimmed milk powder, white sugar, sorbitol, sucralose, and starch into a tank mixer for pre-mixing for 15 minutes.

[0084] Step 2: Dry the material obtained in Step 1 at 40° C. for 120 minutes.

[0085] Step 3: Add the material obtained in Step 2 into a multi-directional motion mixer, add magnesium stearate, and mix for 30 minutes.

[0086] Step 4: Manually compress the material obtained in step 3 or add it to a rotary tablet press for tableting. The controlled pressure is 35KN, and the tableting amount is 0.91-0.93g / tablet to obtain candy tablets. See figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com