Preparation method of a three-dimensional composite porous scaffold and three-dimensional composite porous scaffold

A technology of three-dimensional composite and porous scaffolds, which is applied in the preparation of three-dimensional composite porous scaffolds, and in the field of three-dimensional composite porous scaffolds, can solve the problems of pore-forming agent residues and lack of interconnected pore structures in scaffolds, and achieve high porosity and easy promotion Good use and interoperability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

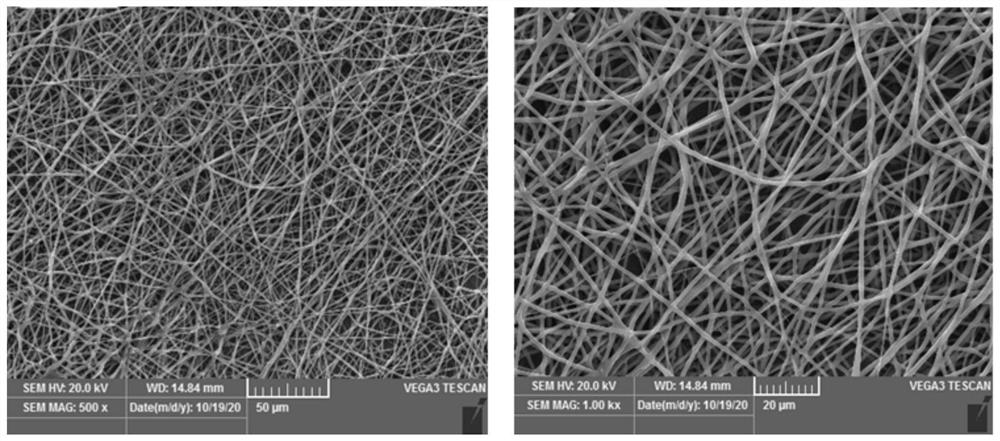

[0041] S1: Take dichloromethane and N,N-dimethylformamide in a ratio of 4:1 by volume, and mix the dichloromethane and N,N-dimethylformamide evenly to obtain an organic solvent, and then according to The mass ratio of the organic solvent to the sum of the mass of polycaprolactone (PCL) and cellulose nanocrystals (CNC) is 16%. Weigh PCL and CNC, and stir and mix PCL and CNC with the organic solvent to dissolve them. And according to the electrospinning parameters of a voltage of 18kV, a sample injection speed of 0.8mL / h, a distance between the needle and the receiver of 20cm, and a needle of 20G, electrospinning was performed to obtain a nanofiber membrane with a diameter of 200-600nm; wherein , and the mass ratio of CNC added to PCL is 3:100;

[0042] S2: Mix according to the volume ratio of 1:1 to obtain a mixed solvent of absolute ethanol and deionized water, then weigh the nanofiber membrane obtained in step S1, weigh 4g of the nanofiber membrane and add it to 200mL of the ...

Embodiment 2

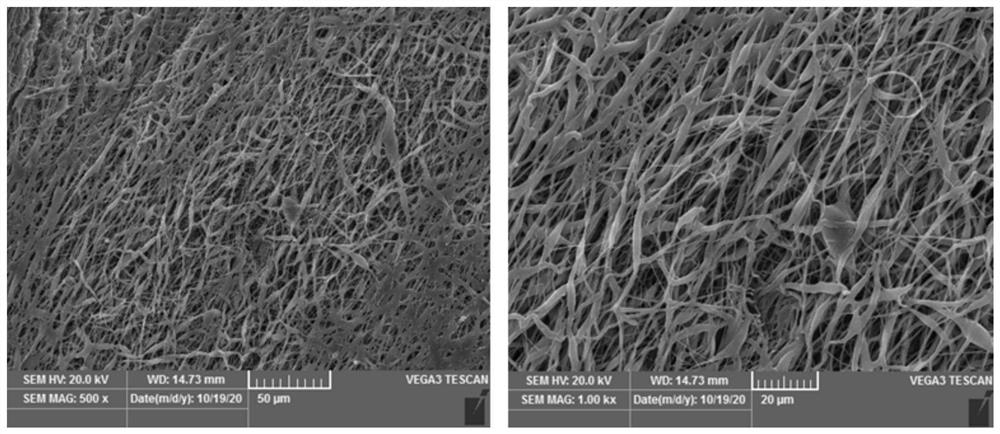

[0045] S1: Take dichloromethane and N,N-dimethylformamide in a ratio of 3:2 by volume, and mix the dichloromethane and N,N-dimethylformamide evenly to obtain an organic solvent, then follow The mass ratio of the organic solvent to the sum of the mass of polycaprolactone (PCL) and cellulose nanocrystals (CNC) is 20%. Weigh PCL and CNC, and stir and mix PCL and CNC with the organic solvent to dissolve them. And according to the electrospinning parameters of voltage 18kV, sample injection speed 0.8mL / h, the distance between the needle and the receiver is 20cm, and the needle is 20G, electrospinning is performed to obtain a nanofiber membrane with a diameter of 200-600nm;

[0046] S2: mix according to the volume ratio of 1:2 to obtain a mixed solvent of absolute ethanol and deionized water, then weigh the nanofiber membrane obtained in step S1, weigh 4g of the nanofiber membrane and add it to 200mL of the mixed solvent, and mechanically stir and break it into intermittent Accelera...

Embodiment 3

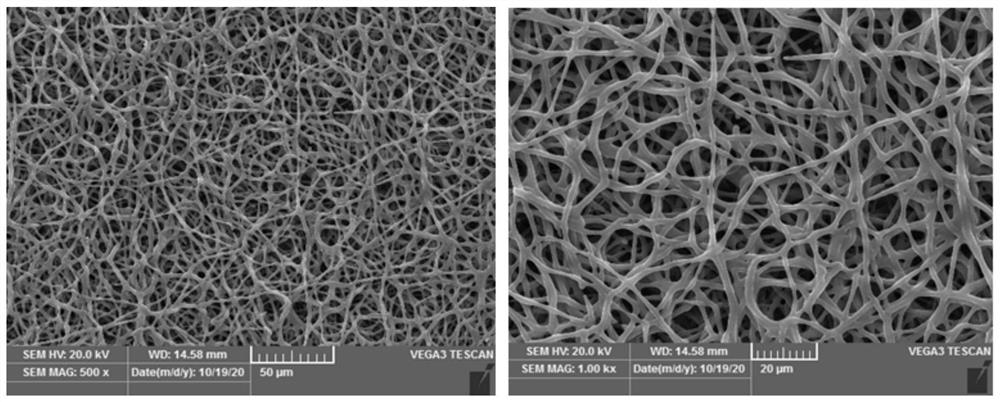

[0049] In step S1, the mass ratio of the organic solvent to the sum of the mass of PCL and CNC was 14%, and other preparation steps were basically the same as those in Example 1, and product C was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com