Cross-linked resin modified matting material for BOPP matting film and preparation method of cross-linked resin modified matting material

A cross-linked resin and matting film technology, which is applied in the field of plastic films, can solve problems affecting the uniform distribution of matting material on the surface of the core layer, low haze of BOPP matting film, and limited fluidity of matting material, so as to improve the uniformity of matting , Reduce the thickness of the matte layer, and expand the effect of the difference in responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

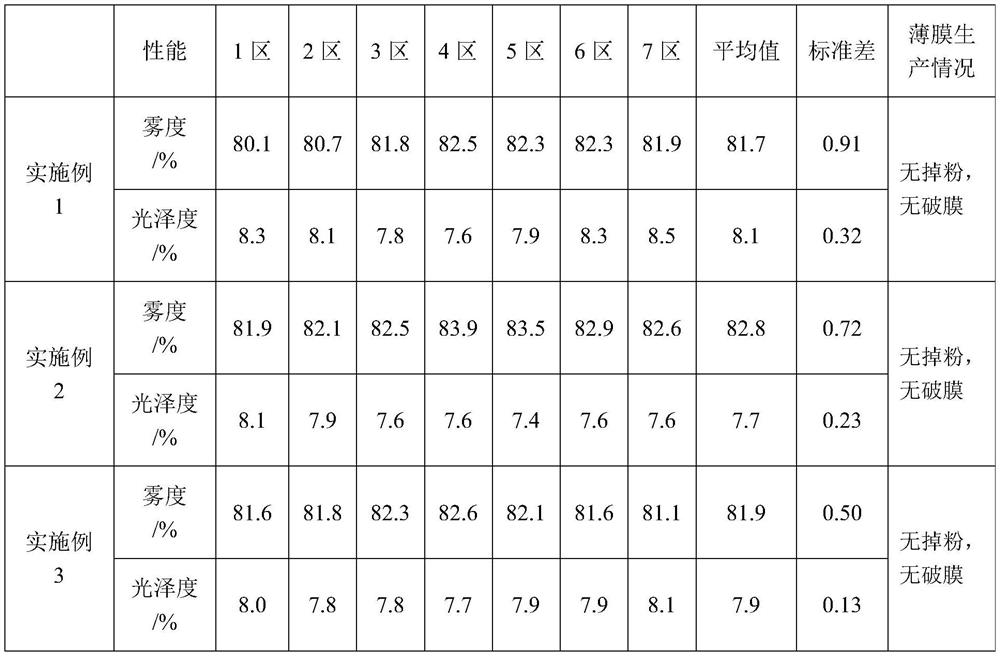

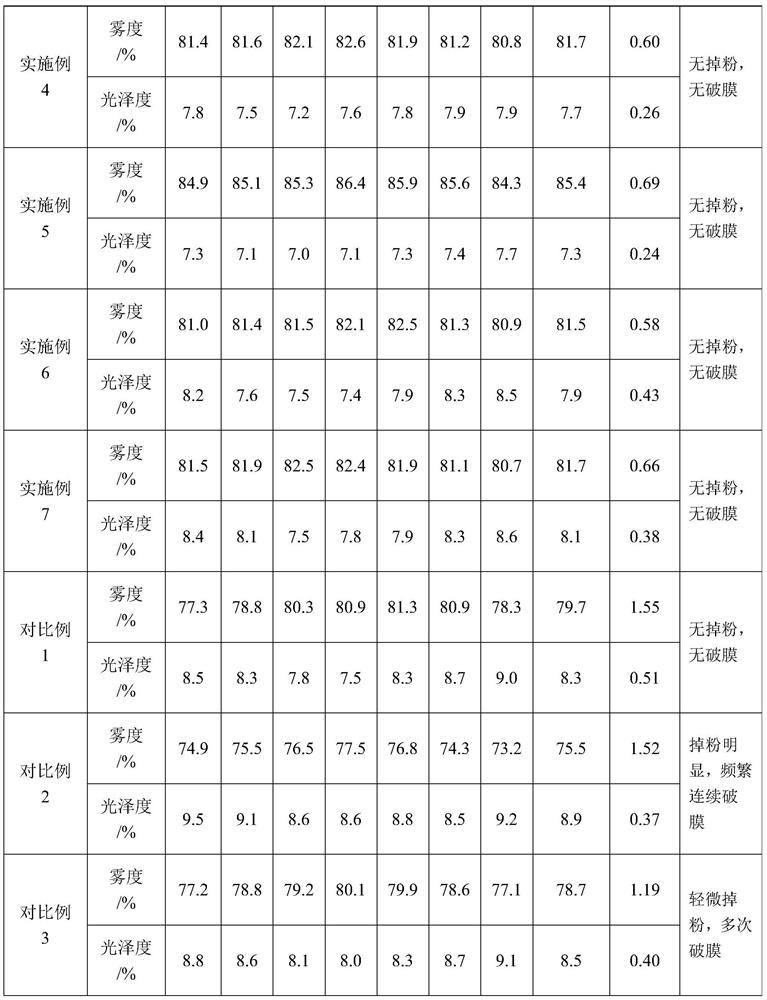

Embodiment 1

[0018] The cross-linked resin modified matting material for BOPP matting film in the present embodiment, its components include: polypropylene 51%, high-density polyethylene 35.7%, cross-linked high-density polyethylene powder 9%, compatibilization 4% of antioxidant, 0.3% of antioxidant; wherein, the components of cross-linked high-density polyethylene powder include: 99% of high-density polyethylene, 1% of radiation cross-linking sensitizer.

[0019] Among them, polypropylene is ternary copolymerized polypropylene with a density of 0.895g / cm 3 , the melt index is 5.5g / 10min under the test conditions of temperature 230°C and load 2.16kg; the density of high-density polyethylene is 0.946g / cm 3 , the melt index is 1.2g / 10min under the test conditions of temperature 190℃ and load 2.16kg; the compatibilizer is linear low density polyethylene with a density of 0.936g / cm 3 , the melt index is 5.3g / 10min under the test conditions of a temperature of 190°C and a load of 2.16kg; the a...

Embodiment 2

[0024] The cross-linked resin modified matting material for BOPP matting film in the present embodiment, its components include by mass percentage: 48.7% of polypropylene, 30% of high-density polyethylene, 15% of cross-linked high-density polyethylene powder, compatibilization 6% of antioxidant, 0.3% of antioxidant; wherein, the components of cross-linked high-density polyethylene powder include: 98.5% of high-density polyethylene, and 1.5% of radiation cross-linking sensitizer.

[0025] Among them, polypropylene is ternary copolymerized polypropylene with a density of 0.910g / cm 3 , the melt index is 5g / 10min under the test conditions of temperature 230°C and load 2.16kg; the density of high-density polyethylene is 0.946g / cm 3 , the melt index is 1.2g / 10min under the test conditions of temperature 190℃ and load 2.16kg; The oxygen agent is a mixture of 1010 and 168 mass ratio = 1:2.

[0026] The preparation method of the cross-linked resin modified matting material for BOPP m...

Embodiment 3

[0028] The cross-linked resin modified matting material for BOPP matting film in this embodiment comprises: 47.2% polypropylene, 25.5% high-density polyethylene, 18% cross-linked high-density polyethylene powder, compatibilization 9% of antioxidant, 0.3% of antioxidant; wherein, the components of cross-linked high-density polyethylene powder include: 98.3% of high-density polyethylene, and 1.7% of radiation cross-linking sensitizer.

[0029] Among them, polypropylene is binary copolymerized polypropylene with a density of 0.900g / cm 3 , the melt index is 6.5g / 10min under the test conditions of temperature 230°C and load 2.16kg; the density of high-density polyethylene is 0.951g / cm 3 , the melt index is 2.2g / 10min under the test conditions of a temperature of 190°C and a load of 2.16kg; the compatibilizer is EPDM rubber, the ethylene content is 52wt%, and the ethylidene-norbornene content is 4.3wt%; The antioxidant is a mixture of 1010 and 168 with a mass ratio of 1:2.

[0030...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com