Pickling mixed-flow production process for glossy aluminum alloy wheel

A production process and technology for aluminum alloy wheels, which are applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., and can solve problems such as occupation, large equipment investment, and large production space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

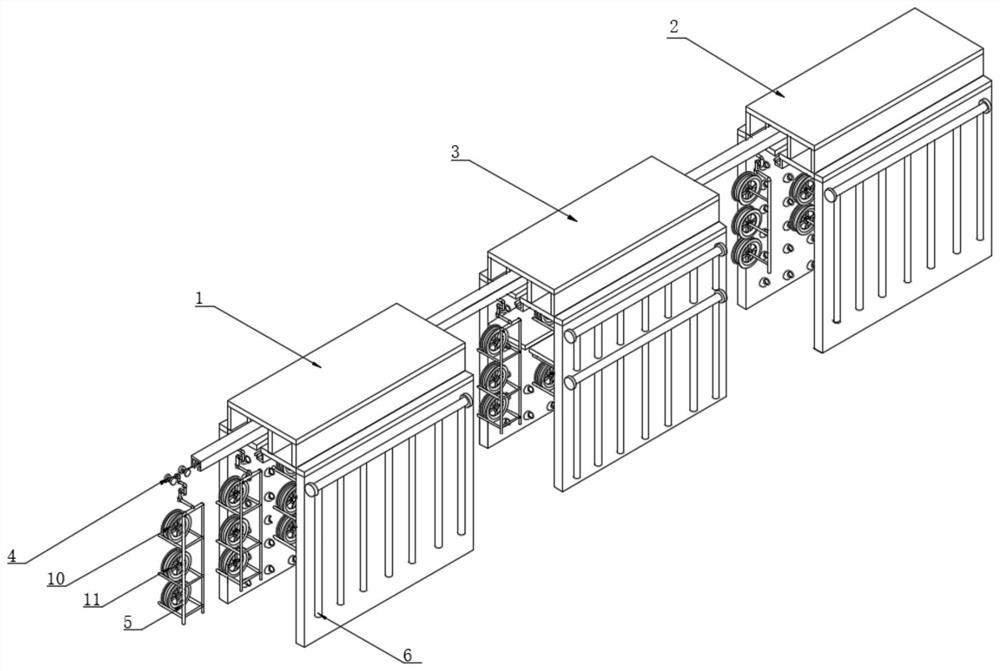

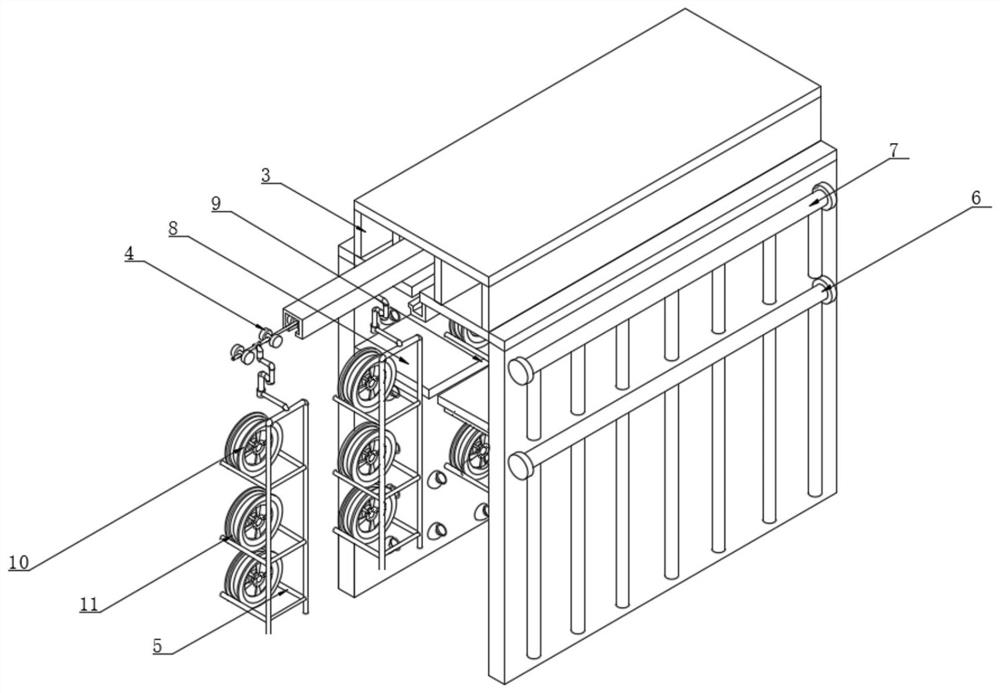

[0026] Such as Figure 1-2 As shown, the present invention provides a technical solution: a pickling mixed-flow production process for bright aluminum alloy wheels, including a treatment process and a treatment mechanism. The treatment mechanism includes: a low-concentration pickling chamber 1, a high-concentration pickling chamber 3 and a pure Wash room 2.

[0027] Low-concentration pickling chamber 1, pure water washing chamber 2 and high-concentration pickling chamber 3 all include catenary 4, support 5, rail, nozzle, bright aluminum alloy wheel hub 10, cleaning pipe 6 and ordinary aluminum alloy hub 11, catenary The upper surface of 4 is fixedly connected to the upper surface of the inner wall of low-concentration pickling chamber 1 through rails, the lower surface of catenary 4 is fixedly clamped with the tops of several brackets 5, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com