Production method of ceramic filling type hydrocarbon resin copper-clad plate

A technology of hydrocarbon resin and production method, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., and can solve the anisotropy of glass fiber cloth impregnation methods, performance differences, high-frequency microwave composite dielectric substrates Difficult preparation and other problems, to achieve good control of thickness uniformity and solve the effect of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for producing a ceramic-filled hydrocarbon resin copper-clad laminate, the specific implementation steps are as follows:

[0019] (1) Use silane coupling agent to carry out surface treatment to ceramic powder, and the consumption of silane coupling agent is 2% of ceramic powder;

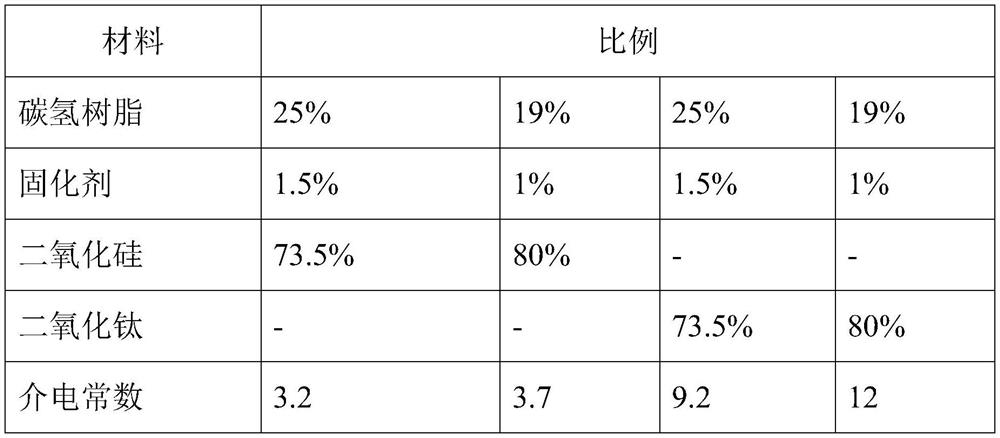

[0020] (2) Proportioning is carried out according to (1-A-B) ceramic powder+A hydrocarbon resin+B curing agent, wherein A and B are percentages by weight, and the total mass fraction of ceramic powder, hydrocarbon resin and curing agent is 1, Add an appropriate amount of cyclohexane as a solvent, adjust the viscosity, and use a stirring device or a pulping device to mix evenly; the content of ceramic powder is 70% to 80%, the content of hydrocarbon resin is between 20% and 30%, and the content of curing agent is 1 % to 3%, the hydrocarbon resin is one or more of polybutadiene, styrene-butadiene-divinylbenzene copolymer, polyisoprene, and the ceramic powder is titanium dioxide, di One...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com