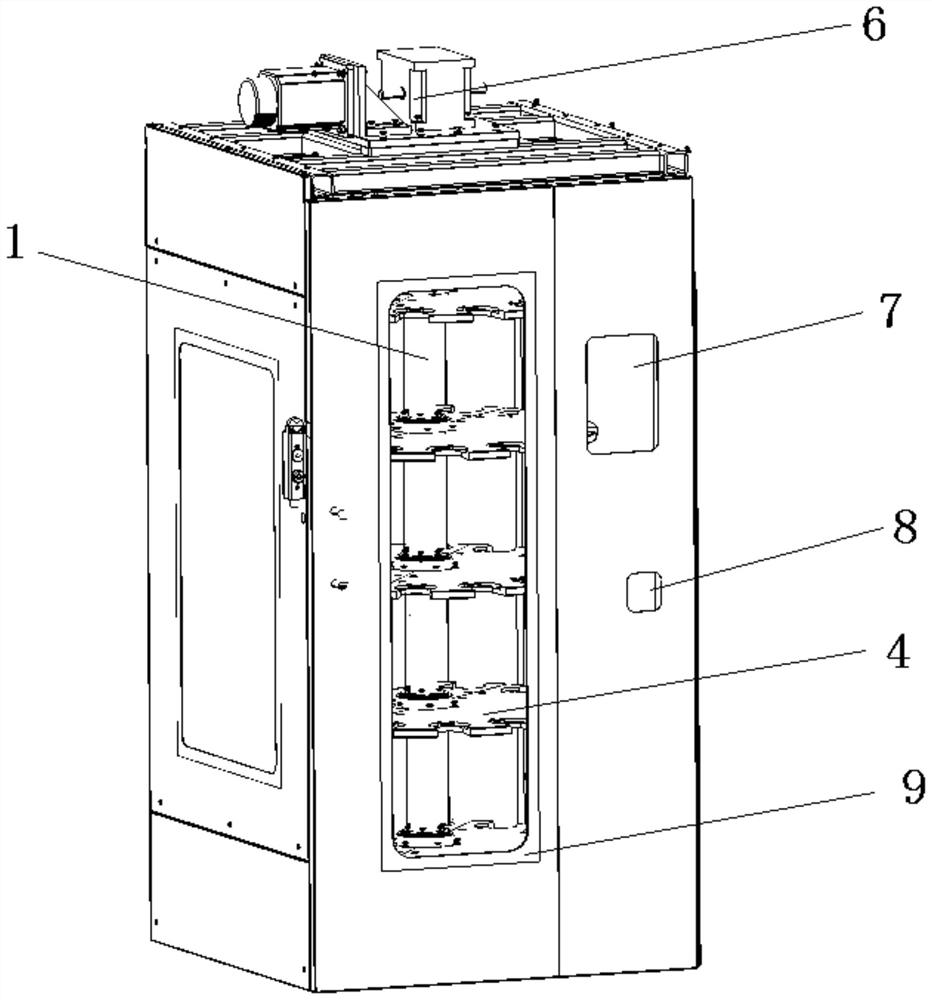

Stock bin applied to intelligent warehousing system, and operation method thereof

A silo and flange technology, used in the field of intelligent tool storage, can solve problems such as operation errors, damage to machine tool spindles or tools, machine tool accuracy and performance degradation, etc., to avoid information errors, reduce downtime, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific embodiments.

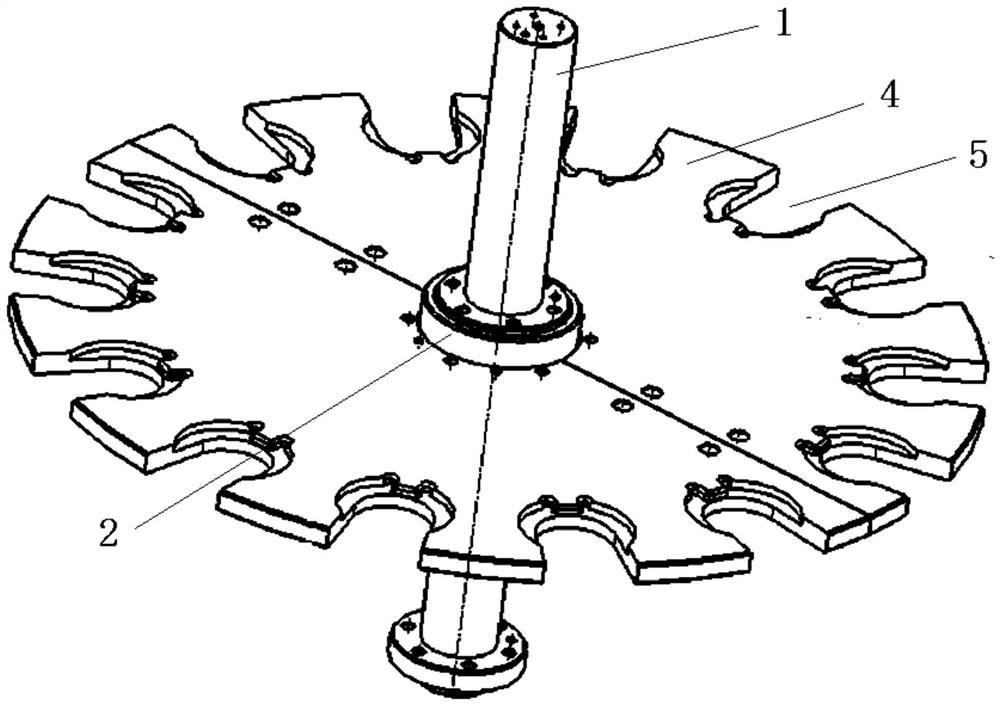

[0042] The invention discloses a cutter head rotating assembly for storing cutters, comprising:

[0043] Rotation center axis 1 and multi-layer cutter head 4;

[0044] The cutter discs 4 of each layer are fixed on the shaft rod on the central axis of rotation 1 in an axially spaced manner through connecting pieces;

[0045] And on the outer edge of each layer of the cutter head 4, a plurality of card slots 5 for accommodating the cutter handle are distributed at intervals. The card slot 5 realizes the positioning of the tool handle.

[0046] The cutter head 4 is in the shape of a disc as a whole, and is formed by splicing two semi-circular structures.

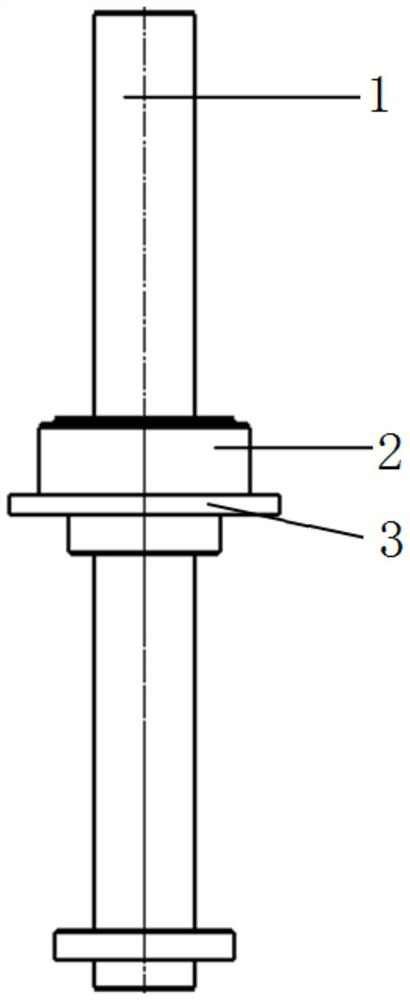

[0047] The connecting piece includes a flange connecting plate 3 and a cutter head support seat 2;

[0048] The cutter head 4 is fixed on the blue connecting plate 3 by bolts;

[0049] The cutter head support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com