A biomass catalytic pyrolysis coupled on-line upgrading to produce liquid fuel reaction device

A technology of catalytic pyrolysis and liquid fuel, applied in the preparation of liquid hydrocarbon mixture, petroleum industry, etc., can solve energy loss, equipment cost limitation, economic competitiveness, deactivation of unstable component condensation polycondensation catalyst, and far difference in fuel characteristics and other problems to achieve the effect of reducing upgrading equipment, avoiding energy loss, and improving the quality of bio-oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with the accompanying drawings and with reference to the data.

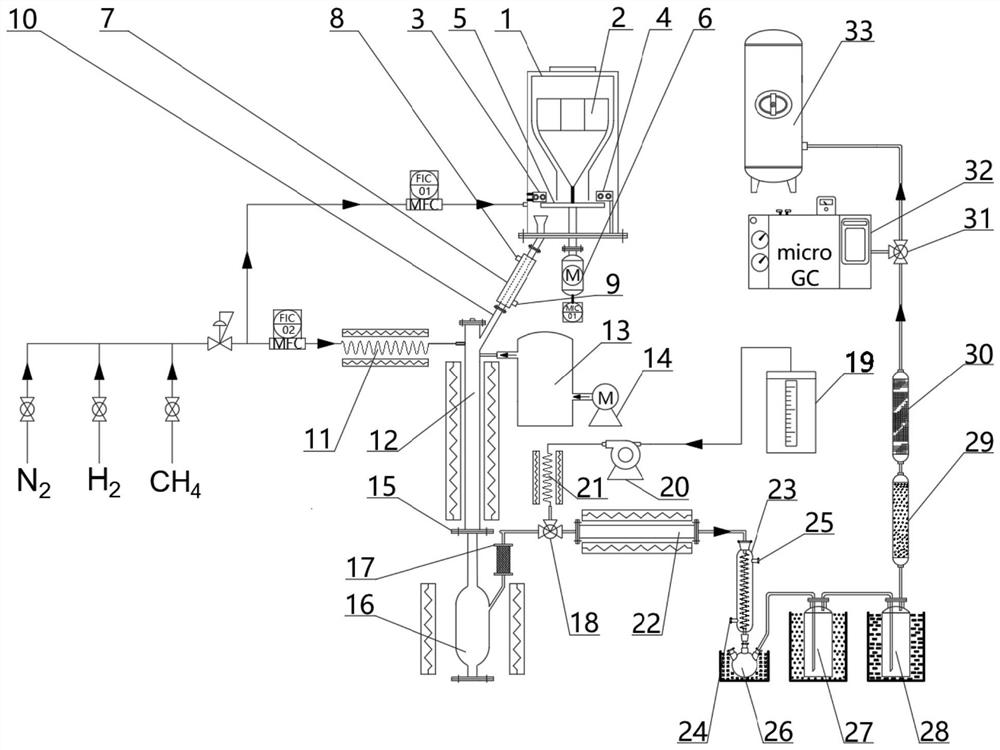

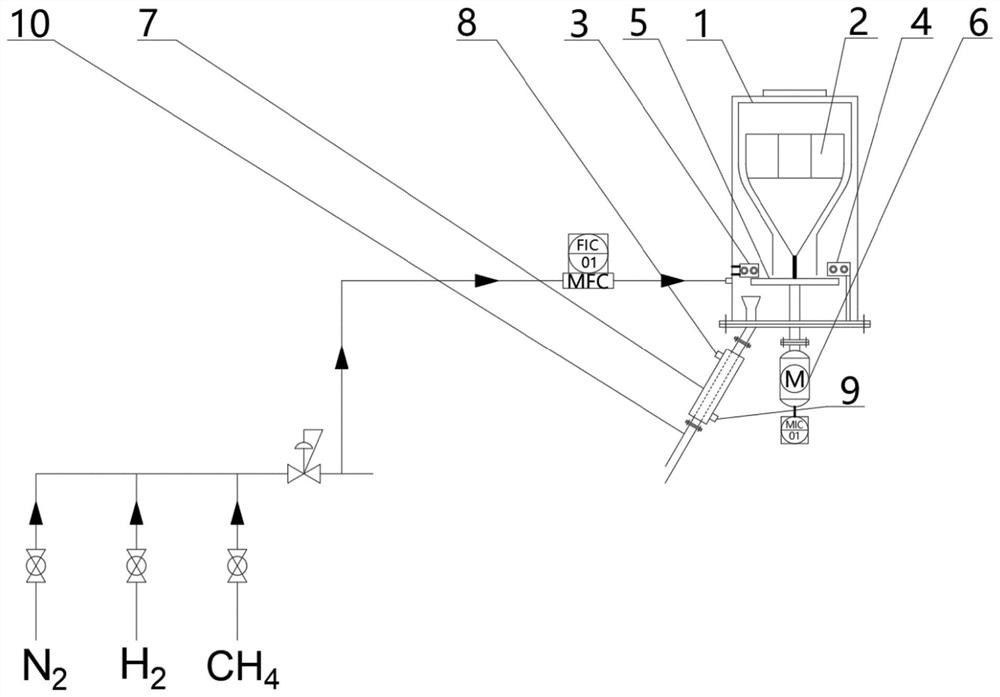

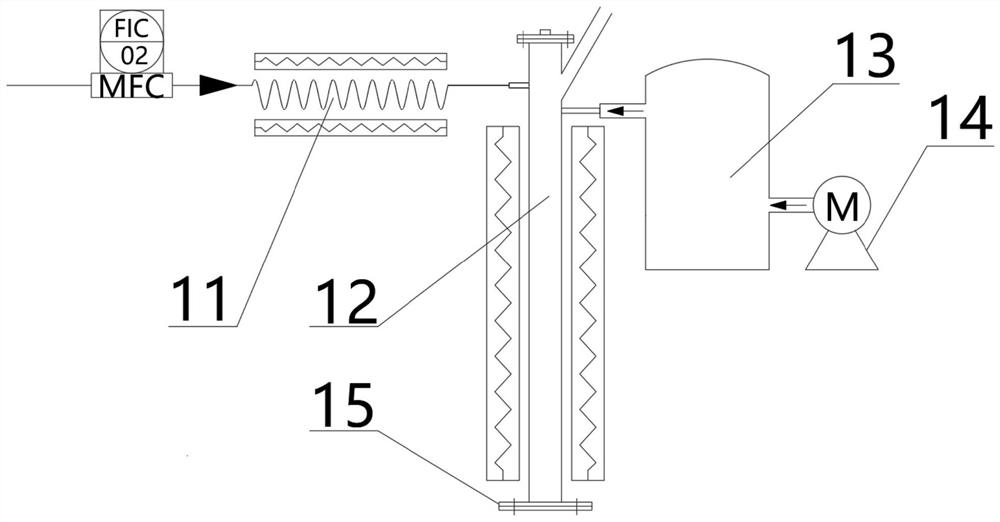

[0026] as Figure 1 As shown, a biomass catalytic pyrolysis coupling online quality extraction liquid fuel reaction apparatus comprises a sequentially connected feeding system, a pyrolysis reaction system, a coke collection system, an online catalytic quality extraction system, a multi-stage controllable condensing system, and a gas online detection and collection system. Wherein, the feeding system is connected to the pyrolysis reaction system via a gas path connection pipe and a discharge inclined pipe 10. The pyrolysis reaction system is connected to the coke collection system by flange disc 15. Coke collection system is connected to the online catalytic quality improvement system by the first three-way valve 18, and the hydrogen supply device and the lifting reactor 22, the online quality improvement catalytic system and the front and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com