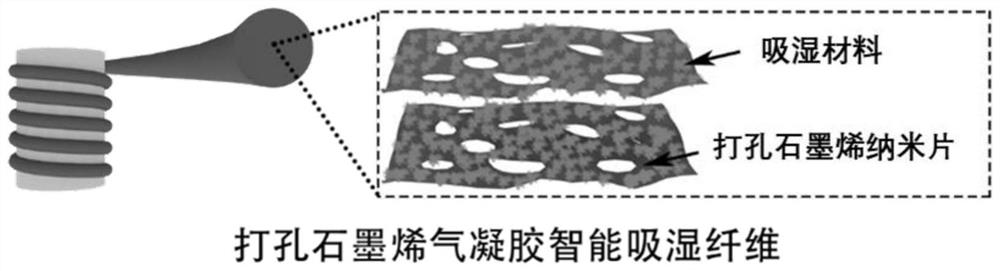

Perforated graphene aerogel moisture absorption fiber as well as preparation method and application thereof

A graphene aerogel, graphene hydrogel technology, applied in the direction of carbon fiber, fiber processing, fiber chemical characteristics, etc., can solve the problems of inability to mass production, complex processing technology of microfluidic air water intake device, etc. Excellent electric heating, mild reaction conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a preparation method of the perforated graphene airgel hygroscopic fiber, comprising the following steps:

[0051] Provide perforated graphene hydrogel fibers or perforated graphene airgel fibers; and

[0052] Fill the perforated graphene hydrogel fiber or perforated graphene airgel fiber with a moisture absorbent by means of solution filling, so that the moisture absorbent enters and fills the three-dimensional porous network structure of the gel fiber , after drying, the perforated graphene airgel hygroscopic fiber is obtained.

[0053] In the present invention, the perforated graphene hydrogel fiber is prepared from a perforated graphene oxide dispersion by a spinning method, and the perforated graphene airgel fiber is prepared from the perforated graphene water The gel fiber is obtained after drying. Among them, the perforated graphene oxide is obtained by etching the graphene oxide sheet by chemical etching, and the etchant use...

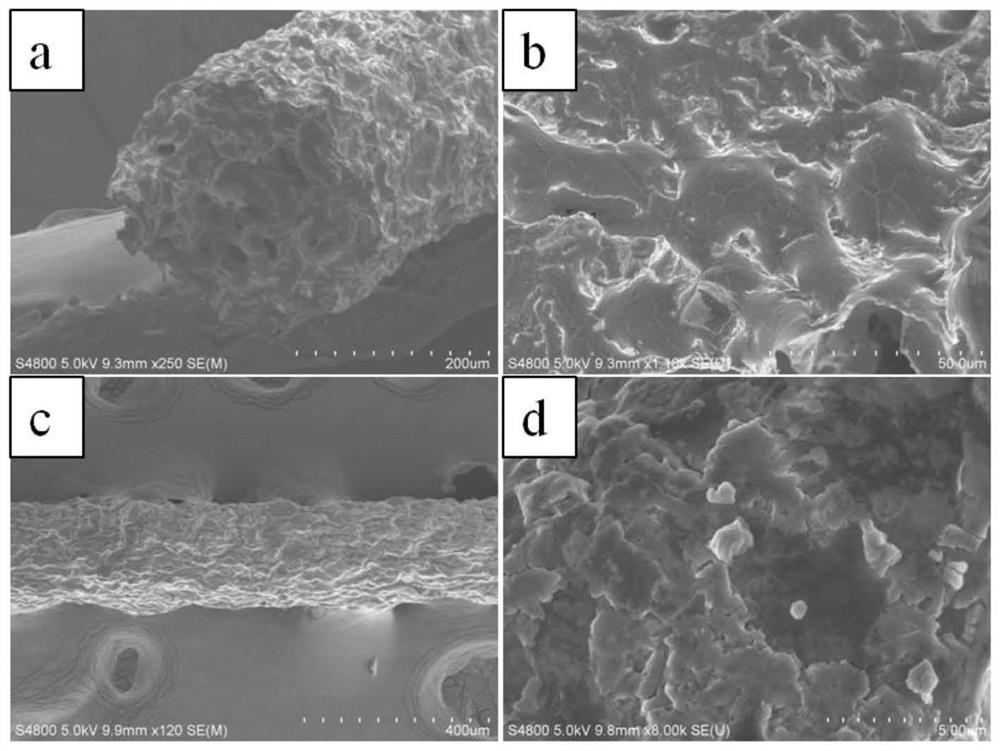

Embodiment 1

[0066] The present embodiment provides a kind of perforated graphene airgel hygroscopic fiber, and its preparation method comprises the following steps:

[0067] (1) Preparation of perforated graphene oxide: add aqueous hydrogen peroxide solution to the graphene oxide dispersion, and react at 100° C. for 30 min.

[0068] (2) Preparation of graphene airgel fiber: the perforated graphene oxide liquid crystal is spun into calcium chloride aqueous solution by wet spinning to obtain perforated graphene oxide hydrogel fiber, and then soaked in hydroiodic acid aqueous solution , followed by supercritical drying to obtain perforated graphene airgel fibers.

[0069] (3) Preparation of perforated graphene / hygroscopic material composite fiber: soak the perforated graphene airgel fiber in 7wt.% lithium chloride aqueous solution, let it stand at normal temperature and pressure for 10h, and put the lithium chloride aqueous solution The fibers were freeze-dried to obtain perforated graphene...

Embodiment 2

[0071] The present embodiment provides a kind of perforated graphene airgel hygroscopic fiber, and its preparation method comprises the following steps:

[0072] (1) Preparation of perforated graphene oxide: add aqueous hydrogen peroxide solution to the graphene oxide dispersion, and react at 100° C. for 1 h.

[0073](2) Preparation of graphene airgel fibers: the perforated graphene oxide liquid crystals were spun into hydrochloric acid / ascorbic acid mixed aqueous solution by wet spinning to obtain perforated graphene hydrogel fibers, and then the hydrogel fibers were subjected to ultra- Perforated graphene airgel fibers obtained by critical drying.

[0074] (3) Preparation of perforated graphene / hygroscopic material composite fiber: soak the perforated graphene airgel fiber in 5wt.% lithium chloride aqueous solution, let it stand at normal temperature and pressure for 15h, and put the lithium chloride aqueous solution The fibers are placed in a 100°C oven to obtain perforate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com