Graphene airgel intelligent phase change fiber, its preparation method and application

A technology of graphene airgel and graphene airgel fiber, which is applied in the field of nanoporous materials and phase change energy storage, can solve the problems of inapplicability, achieve adjustable load capacity, mild reaction conditions, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

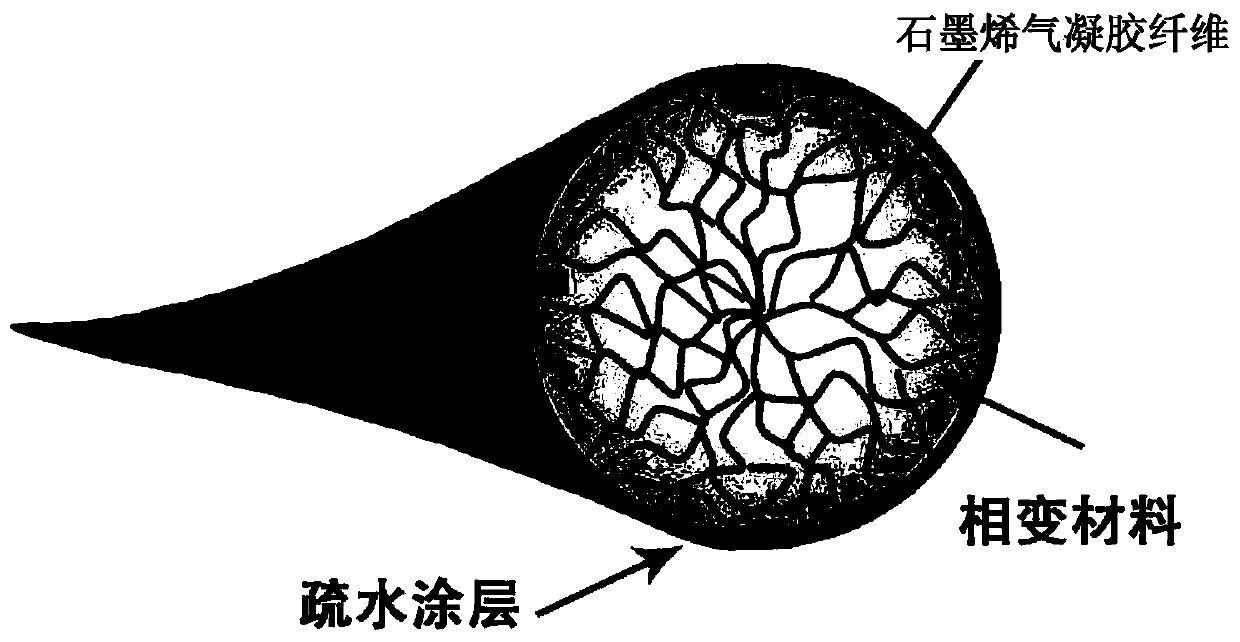

[0060] Another aspect of the embodiments of the present invention also provides the preparation method of the aforementioned graphene airgel smart phase change fiber, which includes:

[0061] providing graphene airgel fibers and / or graphene hydrogel fibers;

[0062] Filling the graphene airgel fiber and / or graphene hydrogel fiber with a phase change material by means of melt filling and / or solution filling to obtain a graphene / phase change material composite fiber;

[0063] A hydrophobic coating is coated on the surface of the graphene / phase change material composite fiber to obtain a graphene airgel intelligent phase change fiber.

[0064] Further, the preparation method may include:

[0065] 1) Spinning preparation of graphene airgel fibers;

[0066] 2) Melt filling and / or solution filling of phase change materials;

[0067] 3) Hydrophobic coating coating.

[0068] In some embodiments, the preparation method includes: preparing graphene hydrogel fibers by spinning techno...

Embodiment 1

[0095] (1) Preparation of graphene airgel fibers: Graphene oxide liquid crystals are spun into HCl / VC mixed aqueous solution by wet spinning to obtain graphene hydrogel fibers, and then the hydrogel fibers are subjected to supercritical drying to obtain graphite olefin airgel fibers.

[0096] (2) Preparation of graphene / phase change material composite fibers: immerse graphene airgel fibers in molten paraffin, and place them in a vacuum environment at 100°C for 10 hours, then hang the fibers containing paraffin wax in an oven at 80°C 1h to remove residual paraffin on the surface of the fiber, followed by cooling at room temperature to obtain a graphene / phase change material composite fiber.

[0097] (3) Preparation of hydrophobic coating: Soak graphene / phase change material composite fiber in fluorocarbon resin solution for 5 seconds, then dry at room temperature to obtain graphene airgel smart phase change fiber, wherein the thickness of hydrophobic coating is 100nm .

[009...

Embodiment 2

[0100] (1) Preparation of graphene airgel fibers: Graphene oxide liquid crystals are spun into HCl / HI mixed aqueous solution by wet spinning to obtain graphene hydrogel fibers, and then graphene hydrogel fibers are obtained by freeze-drying Graphene airgel fibers.

[0101] (2) Preparation of graphene / phase change material composite fibers: soak graphene airgel fibers in molten PEG, and place them in a vacuum environment at 80°C for 1 hour, then hang the fibers containing paraffin in an oven at 80°C 1h to remove residual paraffin on the surface of the fiber, followed by cooling at room temperature to obtain a graphene / phase change material composite fiber.

[0102] (3) Preparation of hydrophobic coating: Soak graphene / phase change material composite fiber in fluorocarbon resin solution for 3-5s, then dry at room temperature to obtain graphene airgel smart phase change fiber, wherein, the thickness of hydrophobic coating 10nm.

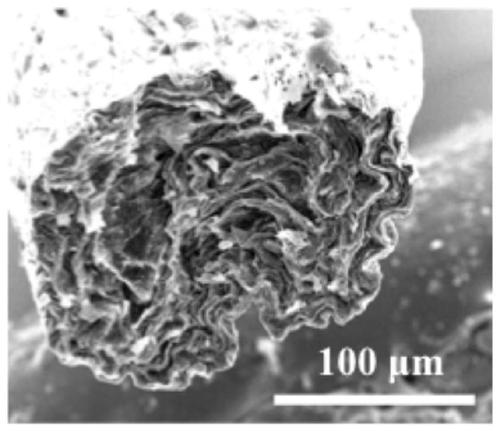

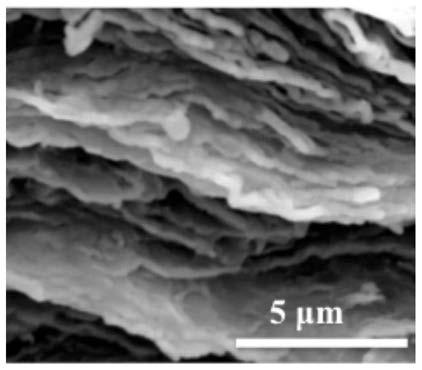

[0103] The scanning electron microscope photo of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com