Device and method for testing multi-wavelength refractive index of a lens

A testing device and technology of refractive index, applied in the field of multi-wavelength refractive index testing devices of lenses, can solve the problems of difficult detection, large measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

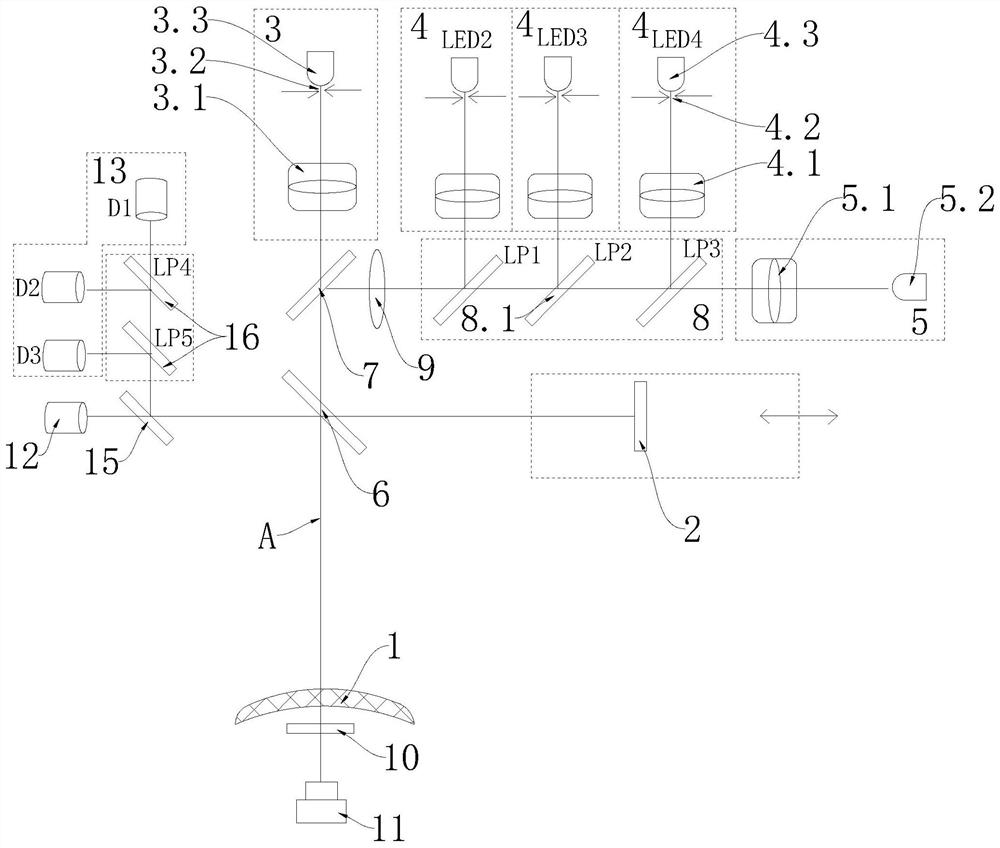

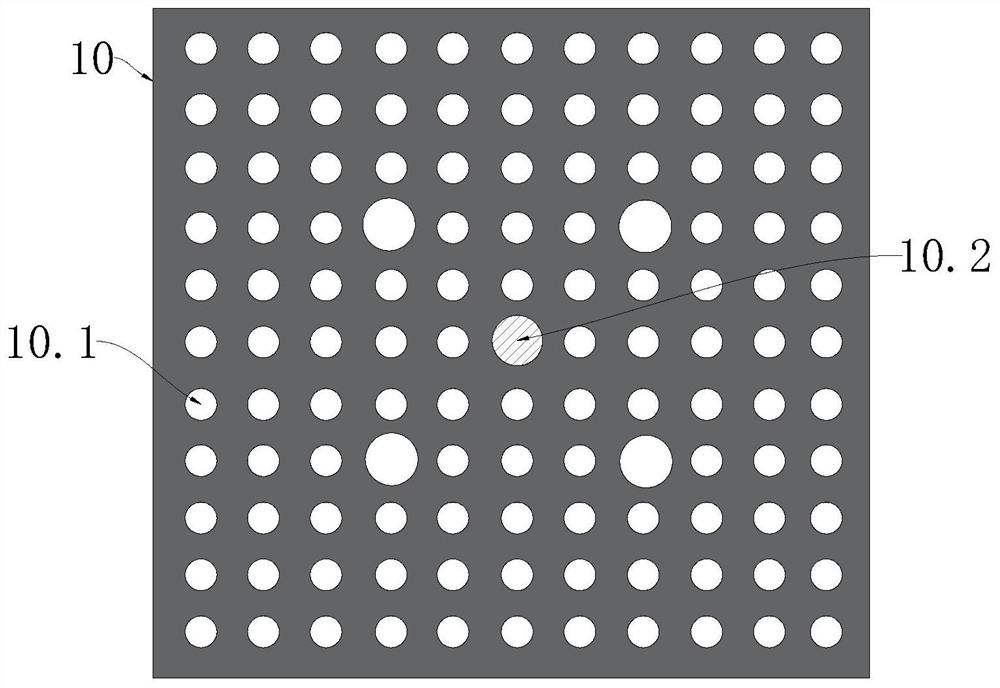

[0031] Such as Figure 1-3 As shown, a lens multi-wavelength refractive index testing device includes a lens to be tested 1, and the lens multi-wavelength refractive index testing device includes a light source assembly, a signal detection module, a moving mirror 2 that moves back and forth at a uniform speed, and a diopter measurement module, wherein the The light source assembly includes a first light source assembly 3 for auxiliary diopter measurement, N groups of second light source assemblies 4 arranged from low to high wavelengths, a third light source assembly 5 for superluminescence, a first spectroscopic assembly 6, a second Spectroscopic assembly 7, the third spectroscopic assembly 8 and focusing lens 9 that each group of second light source assembly 4 is provided with; Described diopter measurement module comprises Hartmann aperture 10 and area array image sensor 11, and described Hartmann aperture 10 is provided with several light-transmitting points 10.1, and the ...

specific Embodiment 2

[0037] Such as Figure 4 As shown, the difference between this specific embodiment and specific embodiment 1 is that the second test light source 4.3 is a white light source, N=1, wherein the spectral range of the white light source covers 460nm-660nm, and the second light transmission hole 4.2 The diameter is 0.15-0.25mm, the light from the white light source becomes parallel light after passing through the second collimating lens 4.1, and the light transmittance of the third beam splitter 8.1 is greater than 90% for 750-1000nm, and greater than 90% for 450-660nm light , for the 450-660nm light reflectance is greater than 90%, between the first photodetection assembly 13 and the fifth beam splitter 16 and between the second photodetection assembly 12 and the fourth beam splitter 15 are respectively provided for transmitting the corresponding wavelength The optical filter 14, the optical filter 14 transmission spectral bandwidth 15nm-30nm, the peak transmittance is greater tha...

specific Embodiment 3

[0039] A lens multi-wavelength refractive index testing method, comprising the following steps:

[0040] (1) Before the lens to be tested is placed, the first test light source is turned on, and the spot array position of the transmitted light beam is monitored by the area array image sensor as a reference position for subsequent position adjustment of the lens to be tested;

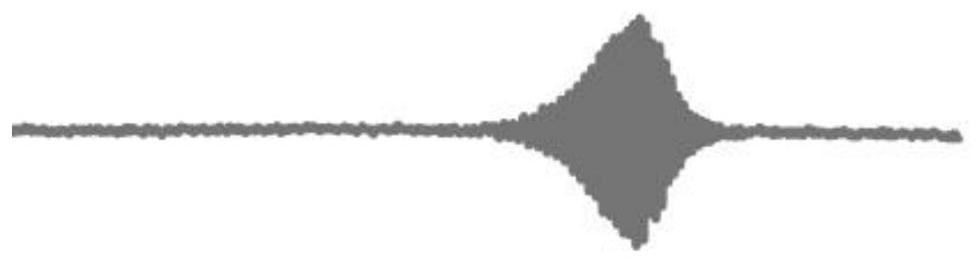

[0041](2) Turn on the N second light source assemblies and the third light source assemblies, and at the same time, move the mirror forward and backward at a constant speed; N first photodetection assemblies respectively monitor the interference signals corresponding to the second light source assemblies, and record The distance X between the moving mirror and the first beam splitting component when interference signals occur 1 , X 2 , X 3 …X N , the interference signal corresponding to the third light source assembly is detected by the second photodetection assembly, and the distance X between the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com