A kind of LED epitaxial structure and preparation method thereof

An epitaxial structure and hole technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of affecting the photon light extraction efficiency of the device, affecting the light extraction efficiency of the chip, reducing the luminous efficiency, etc., to improve the horizontal expansion capability and easy to implement. , the effect of increasing the P-type doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the content of the present invention clearer, the content of the present invention will be further described below with reference to the accompanying drawings. The present invention is not limited to this specific embodiment. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

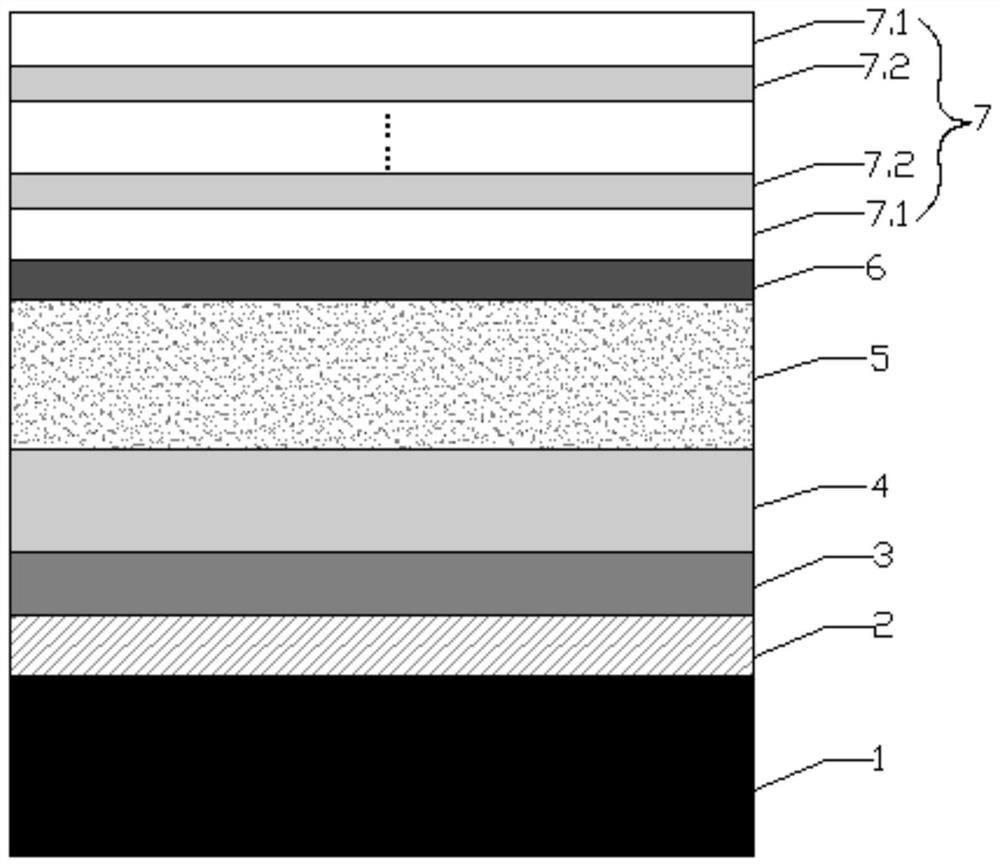

[0047] like figure 1 As shown, an LED epitaxial structure includes:

[0048] substrate 1;

[0049] an N-type semiconductor layer 4 located on the surface of the substrate 1;

[0050] The active layer 5 on the side of the N-type semiconductor layer 4 away from the substrate 1;

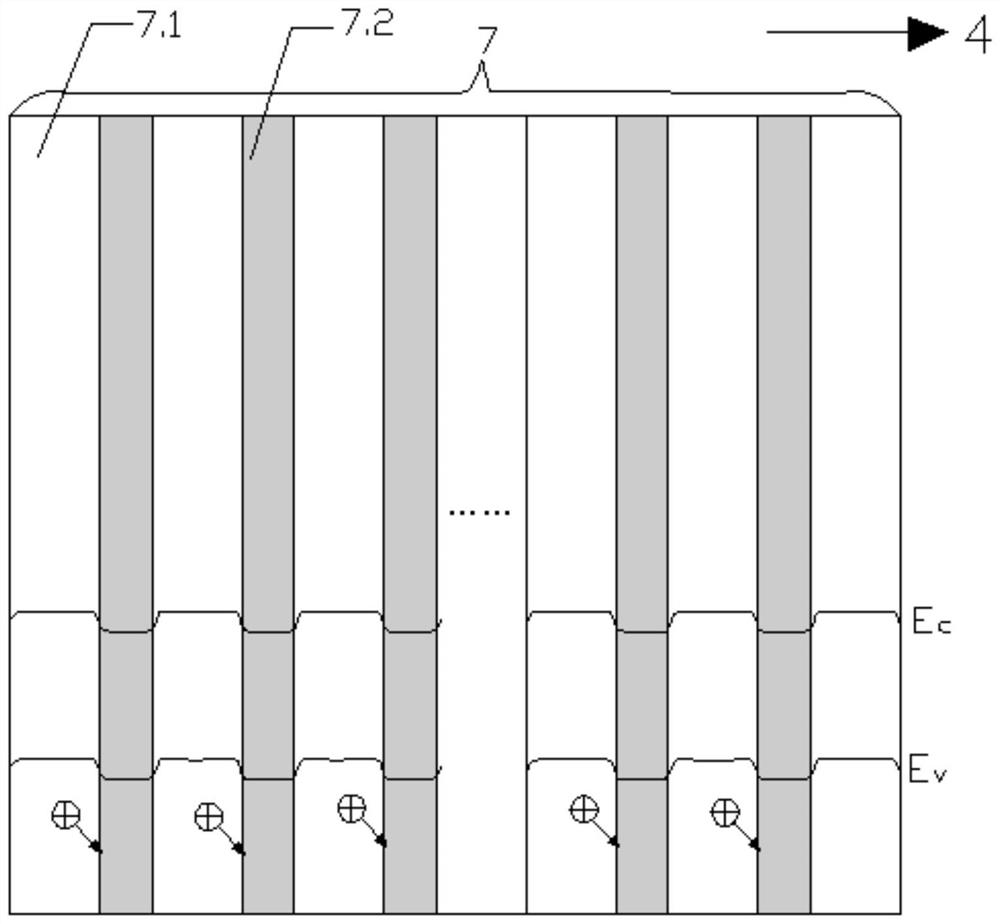

[0051] a composite current spreading layer 7 located on the side of the active layer 5 away from the N-type semiconductor layer 4;

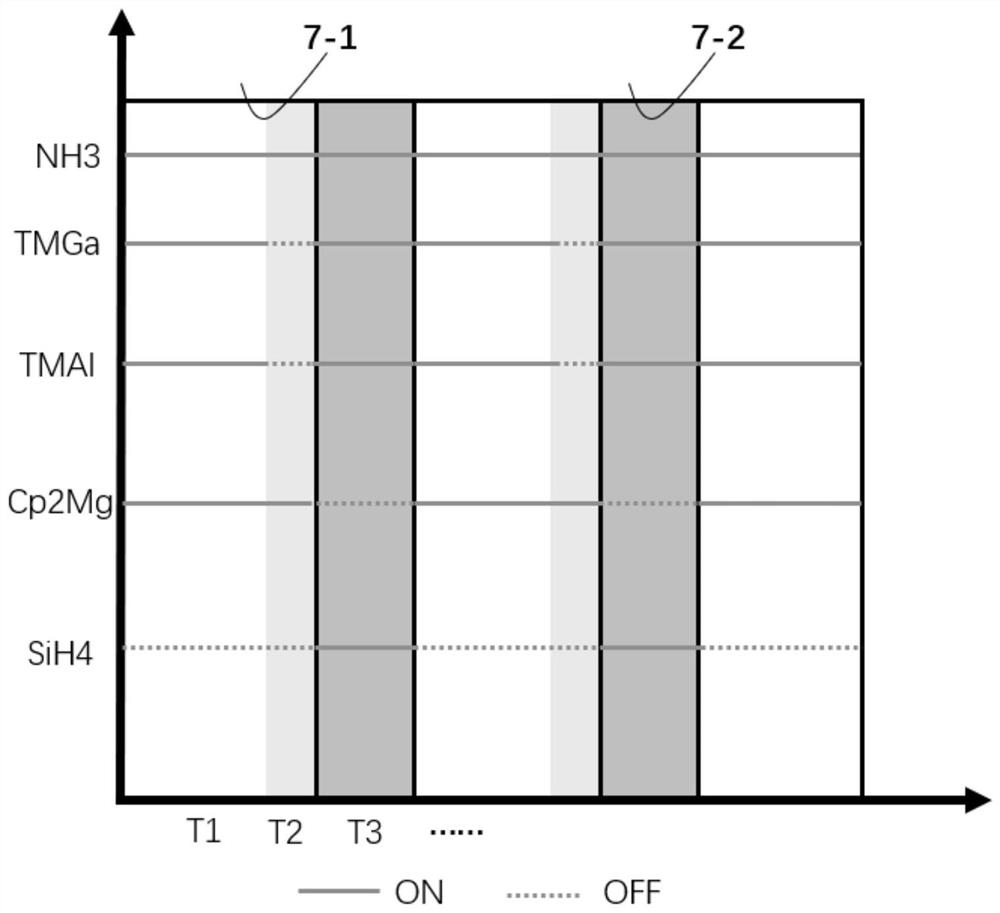

[0052] The recombination current spreading layer 7 includes a number of periodic units composed of a hole supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com