Porous metal implant containing artificial bone meal and preparation method of porous metal implant

A technology for porous metal and implants, which is applied in the fields of prosthesis, tissue regeneration, medical science, etc., can solve the problems of difficult to achieve bone ingrowth, undisclosed organic combination, and long ingrowth time for porous implants. Achieve the effect of inducing ingrowth, excellent bone bearing, and good inducing ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

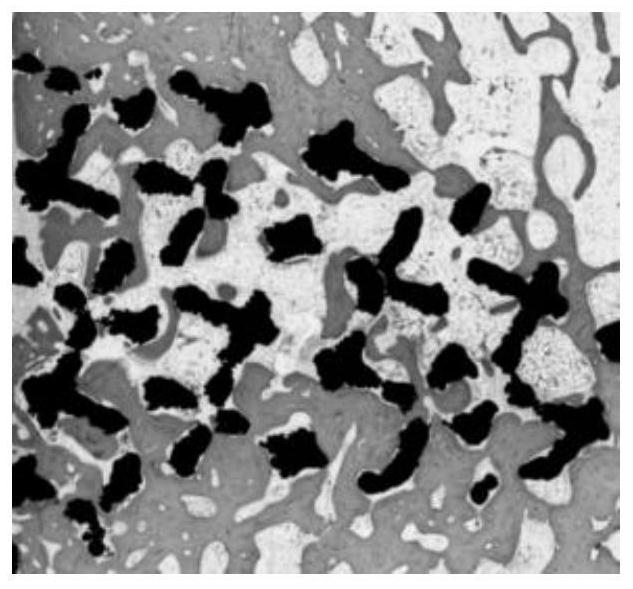

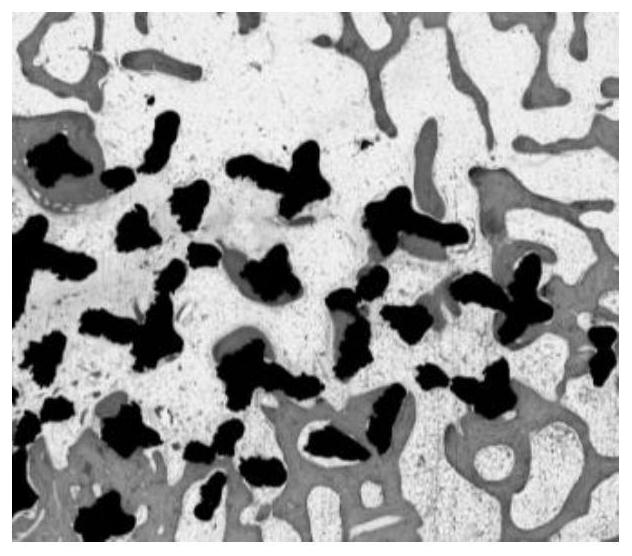

Image

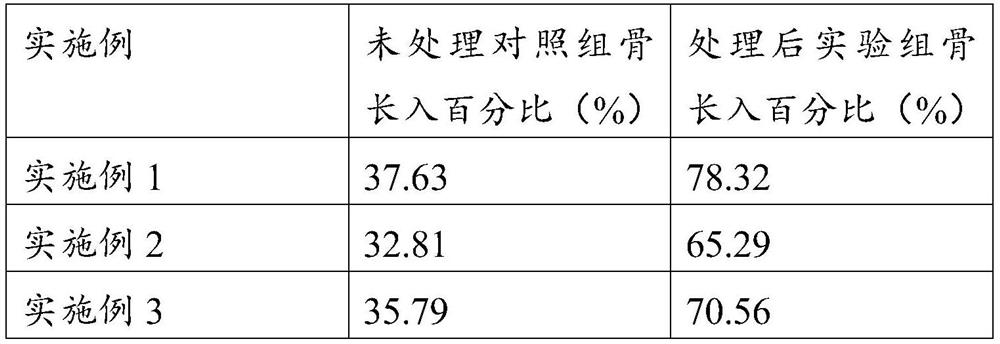

Examples

Embodiment 1

[0026] (1) A 0.1% hyaluronic acid solution is prepared with a phosphate buffer solution; the hyaluronic acid has a molecular weight of 1 million Daltons.

[0027] (2) Disperse the artificial bone powder (allogeneic bone) in the hyaluronic acid solution, and undergo homogenization treatment to form a hyaluronic acid gel in which the artificial bone powder is uniformly dispersed; the homogenization treatment is performed under an ultrasonic vibration environment Stirring by a homogenizer; the particle size range of the artificial bone powder is 20um-100um.

[0028] (3) Submerge the porous metal implant in the hyaluronic acid gel evenly dispersed with artificial bone powder, and give the hyaluronic acid gel a pressure of 5 atmospheres while keeping the gel agitated to promote the coagulation of the hyaluronic acid. The glue fully fills the pores in the porous metal implant.

[0029] (4) Take out the porous metal implant fully filled with hyaluronic acid gel, and remove the water...

Embodiment 2

[0032] (1) Use 0.9% sodium chloride solution to prepare a 0.5% hyaluronic acid solution. The hyaluronic acid has a molecular weight of 1.5 million Daltons.

[0033] (2) Disperse the artificial bone powder (bovine inorganic bone powder) in the hyaluronic acid solution, and after homogenization treatment, form the hyaluronic acid gel in which the artificial bone powder is evenly dispersed; Stir with a quality machine; the particle size range of the artificial bone powder is 20um-100um.

[0034] (3) Submerge the porous metal implant in the hyaluronic acid gel B uniformly dispersed with artificial bone powder, and give the hyaluronic acid gel a pressure of 10 atmospheres while keeping the gel agitated to promote the hyaluronic acid The gel fully fills the pores in the porous metal implant.

[0035] (4) Take out the porous metal implant fully filled with hyaluronic acid gel, and remove the water molecules in the hyaluronic acid gel in the porous metal implant through drying proce...

Embodiment 3

[0038] (1) Prepare a 0.02% hyaluronic acid solution with water. The hyaluronic acid has a molecular weight of 200,000 Daltons.

[0039] (2) Disperse the artificial bone powder (hydroxyapatite powder) in the hyaluronic acid solution, and undergo homogenization treatment to form a hyaluronic acid gel in which the artificial bone powder is uniformly dispersed, and the homogenization treatment is performed in an ultrasonic vibration environment Stir with a homogenizer, and the particle size range of the artificial bone powder is 20um-100um.

[0040] (3) Submerge the porous metal implant in the hyaluronic acid gel evenly dispersed with artificial bone powder, and give the hyaluronic acid gel a pressure of 2 atmospheres while keeping the gel agitated to promote the coagulation of the hyaluronic acid. The glue fully fills the pores in the porous metal implant.

[0041] (4) Take out the porous metal implant fully filled with hyaluronic acid gel, and go through the freeze-drying proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com