A kind of injectable bone cement containing disulfide bond and its preparation method

A bone cement and disulfide bond technology, applied in the field of bone cement, can solve problems such as difficult hydrolysis or enzymatic hydrolysis, unfavorable tissue reconstruction, etc., to achieve the effects of promoting adhesion, benefiting bone repair, and reducing injection pressure

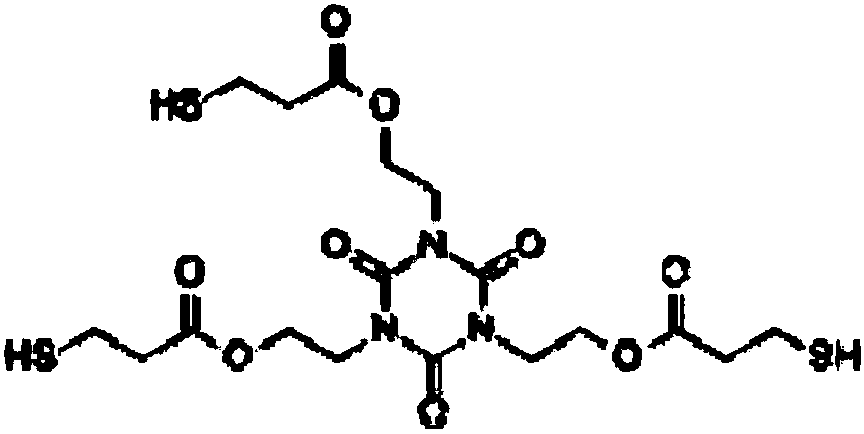

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] 2. A preparation method of the injectable bone cement containing disulfide bonds, comprising the following steps

[0117] Step a: Preparation of solidified liquid: dissolving polymercapto reagent in water, aqueous solution, or mixed solvent compatible with water, pH>5, preferably medium pH value or pH greater than 7;

[0118] Step b: blending and curing: blending the bone cement powder and the curing solution at a liquid-solid ratio of 0.1 to 10 mL:g to obtain the injectable bone cement containing disulfide bonds;

[0119] The bone cement powder contains inorganic calcium salt and acidic reagent, or the pH will be lowered during the curing process.

[0120] 2.1 Preparation of component (I) solid powder

[0121] Conventional preparation methods of inorganic calcium salts are well known to those skilled in the art and will not be repeated here. Taking calcium phosphate as an example, amorphous raw materials are usually prepared, and then sintered to obtain the desired c...

Embodiment 1

[0137] 1. Preparation of Bone Cement Powder

[0138] Calcium phosphate bone cement powder: Phosphorus-based calcium salt bone cement powder composed of β-tricalcium phosphate / tetracalcium phosphate in a molar ratio of 2:1.

[0139] 2. Preparation of Curing Solution

[0140] Polycysteine with a molecular weight of 1 kDa was dissolved in a pH7.2 phosphate buffer with a mass concentration of 20%.

[0141] 3. Harmonize and solidify

[0142] At room temperature, mix 0.5g of bone cement powder and solidification solution according to the liquid-solid ratio of 0.5mL / g, mix it into a paste with a stirring pad, put it into a 1mL disposable syringe, and push it manually for injection. The injection time is about 3 minutes , The curing time is about 12min. Test according to standard ASTM C191.

[0143] Cured at room temperature for 24 hours, the cured product is immersed in water, and it will not collapse within 1 day.

[0144] Weigh 1g of bone cement powder, adjust according to t...

Embodiment 2

[0146] 1. Preparation of Bone Cement Powder

[0147] Calcium phosphate bone cement powder: Phosphorus-based calcium salt bone cement powder composed of β-tricalcium phosphate / tetracalcium phosphate in a molar ratio of 2:1. Add 6% alginic acid by vortex shaking blending method.

[0148] 2. Preparation of Curing Solution

[0149] Polycysteine with a molecular weight of 2 kDa was dissolved in a pH7.2 phosphate buffer with a mass concentration of 10%.

[0150] 3. Harmonize and solidify

[0151] At room temperature, mix 0.5g of bone cement powder and solidification solution according to the liquid-solid ratio of 0.5mL / g, use a stirring pad to blend into a paste, put it into a 1mL disposable syringe, and manually push the injection. The injection time is about 6 minutes , The curing time is about 25min. Test according to standard ASTM C191.

[0152] Cured at room temperature for 24 hours, the cured product is immersed in water, and it will not collapse within 1 day.

[0153]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com