Composite catalyst, method for degrading high-molecular organic compound through cooperation of composite catalyst and electron beam irradiation, and application of composite catalyst in sewage treatment

A composite catalyst, electron beam irradiation technology, applied in the direction of light water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex process, secondary pollution, high cost, achieve distribution Uniform, high load, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

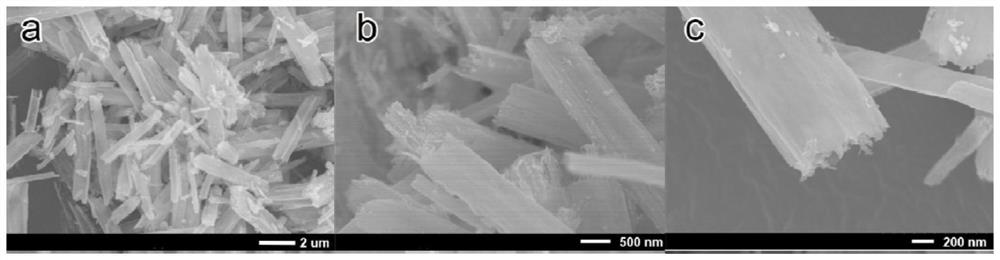

[0075] (1) Measure 5ml of DMF solution in a hydrothermal reaction kettle, then add 0.4g of indium nitrate and 0.2g of terephthalic acid, react at 100°C for 24 hours, and then centrifuge and dry to obtain an indium sacrificial template;

[0076] (2) heat-treat the indium sacrificial template obtained in step (1) for 12 hours under vacuum conditions with a vacuum degree of 120 Pa and a temperature of 120°C; then transfer it to a muffle furnace, and raise the temperature to 500°C at a heating rate of 5°C / min And continue to calcine for 2h to get In with a hollow structure 2 o 3 nanotube;

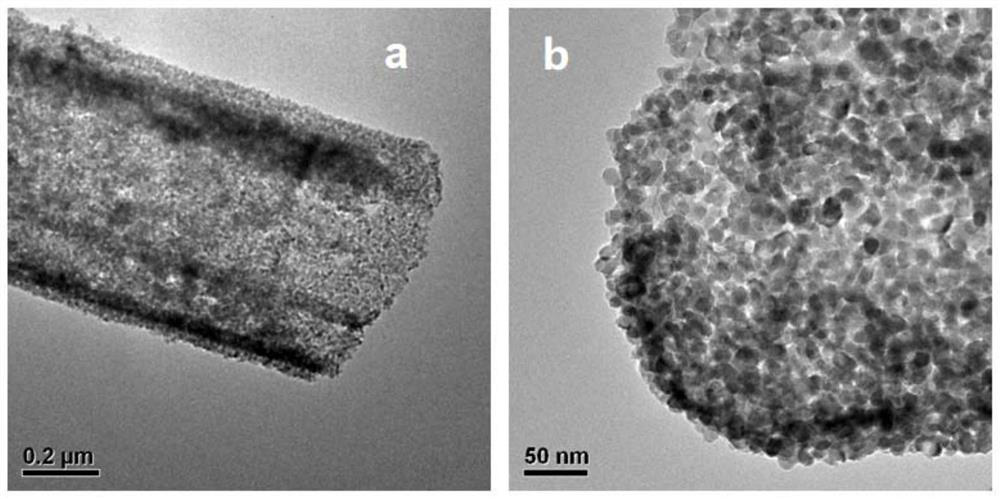

[0077] (3) Take 100mg of In 2 o 3 , then add 10ml of deionized water and sonicate for 10min. After the sample is evenly dispersed, add 10mL of a total of 25mmol molar ratio of cobalt, copper, nickel and manganese chloride salt mixed solution of 1:1.5:0.7:0.3, stir for 1h and then add 100mL concentration 1mol / L reducing agent NaBH 4 ; Place the obtained material in a roasting furnace at 400...

Embodiment A2

[0080] (1) Measure 4.5ml of DMF solution in a hydrothermal reaction kettle, then add 0.35g of indium nitrate and 0.18g of terephthalic acid, react at 100°C for 22 hours, and then centrifuge and dry to obtain an indium sacrificial template;

[0081] (2) heat-treat the indium sacrificial template obtained in step (1) for 11 h under vacuum conditions with a vacuum degree of 130 Pa and a temperature of 110 °C; then transfer it to a muffle furnace, and raise the temperature to 480 ℃ and continue to calcine for 2.2h to obtain In with a hollow structure 2 o 3 nanotube;

[0082] (3) Take 100mg of In 2 o 3 , then add 10ml of deionized water and sonicate for 10min. After the sample is uniformly dispersed, add 10mL of a 1:0.5:2 molar ratio of cobalt, copper and nickel chloride salt mixed solution of 16mmol, stir for 0.8h and then add 40mL of concentration of 3mol / L reducing agent NaBH 4 ; Place the obtained material in a roasting furnace at 350° C. for 4.5 hours to activate it to o...

Embodiment A3

[0084] (1) Measure 5.5ml of DMF solution in a hydrothermal reaction kettle, then add 0.45g of indium nitrate and 0.22g of terephthalic acid, react at 100°C for 26 hours, and then centrifuge and dry to obtain an indium sacrificial template;

[0085] (2) heat-treat the indium sacrificial template obtained in step (1) for 14 hours under vacuum conditions with a vacuum degree of 115 Pa and a temperature of 130°C; then transfer it to a muffle furnace and raise the temperature to 190°C at a rate of 2°C / min , then the temperature was raised to 420°C at a rate of 6°C / min, and then to 500°C at a rate of 4°C / min and continued to be calcined for 2 hours to obtain In with a hollow structure 2 o 3 nanotube;

[0086] (3) Take 100mg of In 2 o 3 , then add 10ml of deionized water and sonicate for 10min. After the sample is evenly dispersed, add 10mL of a total of 20mmol of a mixed solution of cobalt, copper and manganese chloride salts with a molar ratio of 1:2:1. After stirring for 1.5h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com