FeMnO2 nanotube as well as preparation method and application thereof

A nanotube and reaction solution technology, applied in the field of denitration catalyst preparation, can solve the problems of long reaction time, complex preparation method, cumbersome process, etc., and achieve the effects of simple and convenient preparation procedure, easy industrial production, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

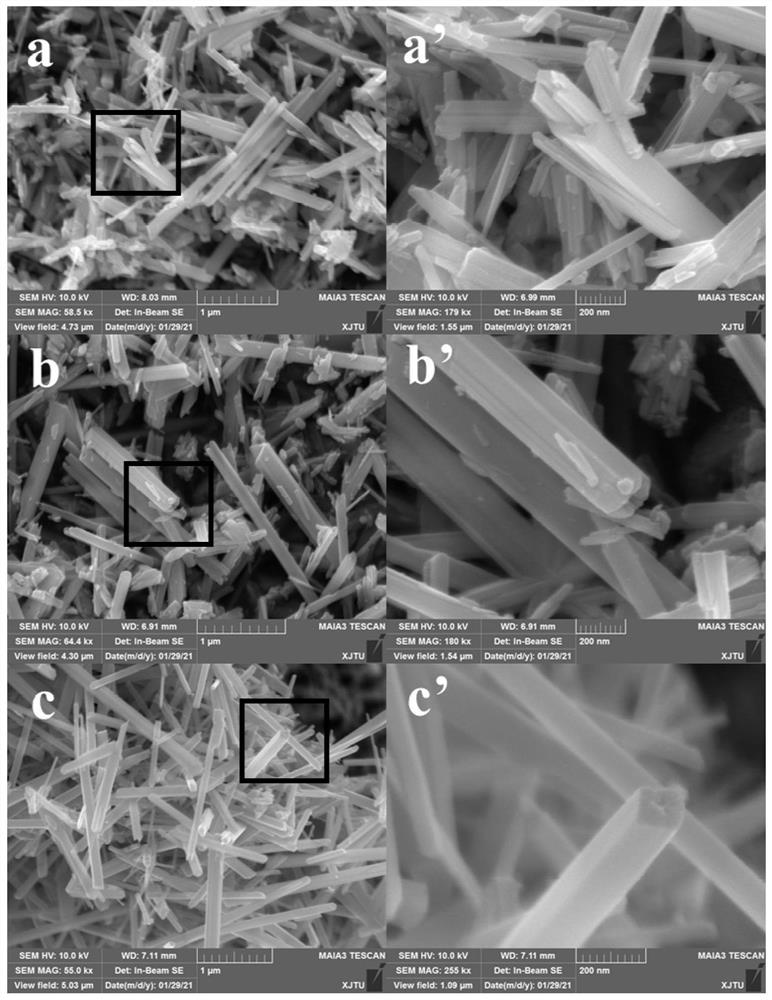

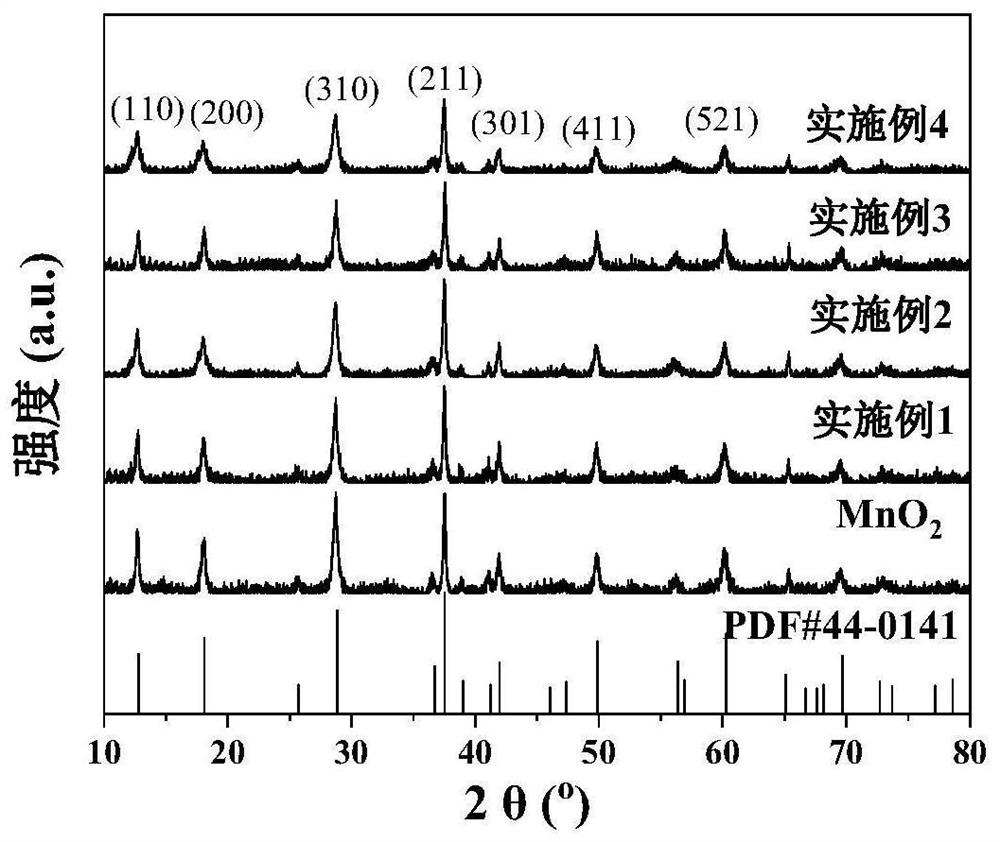

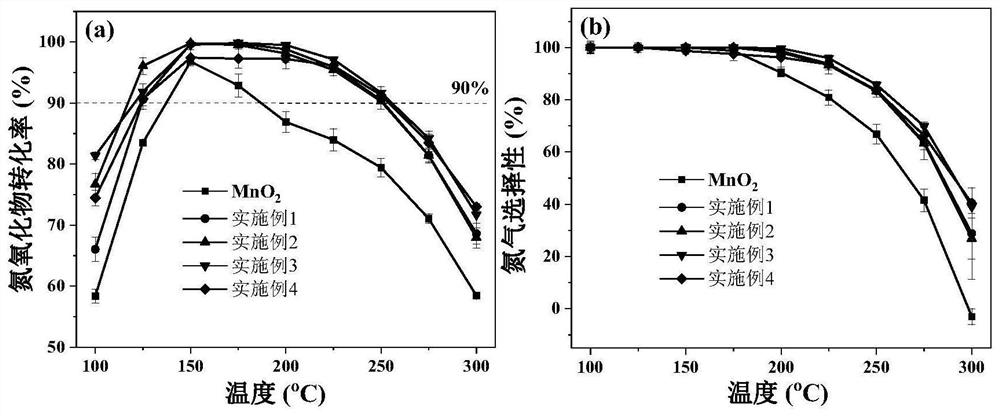

[0032] FeMnO of the present invention 2 The preparation method of nanotube denitration catalyst comprises the following steps:

[0033] 1.58g KMnO 4 and 0.01-0.14g FeSO 4 Add 225ml of deionized water, stir for 5min, then add 37.5% concentrated hydrochloric acid with a total volume of 0.2-0.8% of the solution, stir for 10min, transfer to a 500ml polytetrafluoroethylene reaction tank, and conduct a hydrothermal reaction at 100-180°C for 8-20h. After cooling to room temperature, filter the precipitate in the tank, and wash the product with deionized water or ethanol until neutral. The obtained product is dried overnight at 40-100°C to obtain a new type of FeMnO 2 Nanotube denitrification catalyst.

Embodiment 1

[0035] A kind of high sulfur resistant FeMnO 2 Nanotube, its raw material composition and dosage are as follows: 1.58g KMnO 4 and 0.01g FeSO 4 Add 225ml of deionized water, stir for 5min, then add 0.2% of the total volume of the solution with 37.5% concentrated hydrochloric acid and stir for 10min, transfer to a 500ml polytetrafluoroethylene reaction tank, and conduct a hydrothermal reaction at 100°C for 16h. After cooling to room temperature, the precipitate in the tank was obtained by filtration, and the product was washed with ethanol until neutral. The resulting product was dried overnight at 40°C to obtain the new FeMnO 2 Nanotube denitrification catalyst.

Embodiment 2

[0037] A kind of high sulfur resistant FeMnO 2 Nanotube, its raw material composition and dosage are as follows: 1.58g KMnO 4 and 0.02g FeSO 4 Add 225ml of deionized water, stir for 5min, then add 0.4% of the total volume of the solution with 37.5% concentrated hydrochloric acid and stir for 10min, transfer to a 500ml polytetrafluoroethylene reaction tank, and conduct a hydrothermal reaction at 130°C for 20h. After cooling to room temperature, the precipitate in the tank was obtained by filtration, and the product was washed with deionized water until neutral. The resulting product was dried overnight at 60°C to obtain the new FeMnO 2 Nanotube denitrification catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com