Low-cost method for solidifying arsenic by using multi-element solid waste cementing material for underground filling

A cementitious material and low-cost technology, which is applied in the field of multi-component solid waste cementitious materials for low-cost underground filling to solidify arsenic, can solve the problems of high processing cost, poor stability, and difficulty in large-scale application of live bacteria, and achieves a reduction in the amount of arsenic. and harmless disposal, the preparation process is simple, the effect of reducing diffusion and harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

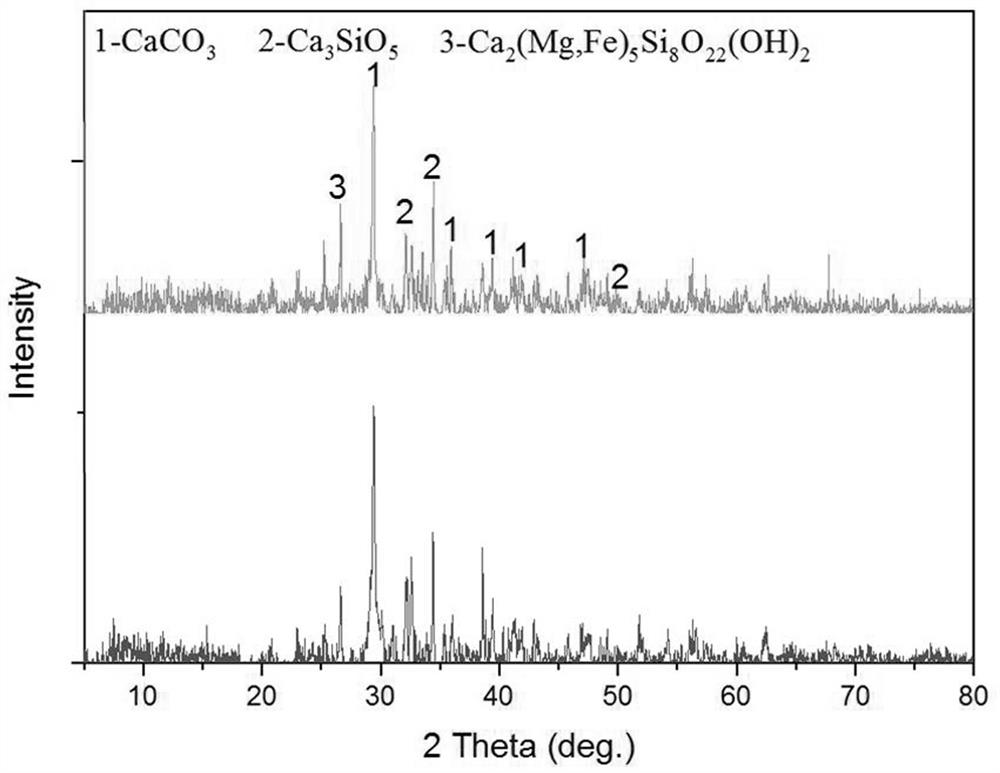

Method used

Image

Examples

Embodiment 1

[0047] In this example, metakaolin comes from a factory in Henan, and its main components are shown in Table 1; blast furnace slag comes from a smelter in Southwest China, and its main components are shown in Table 2; desulfurized gypsum comes from a smelter in Shandong, and its main components are shown in Table 3 Arsenopyrite comes from a mining area in Jiangxi, and its main components are as shown in Table 4;

[0048] Table 1 Metakaolin composition

[0049]

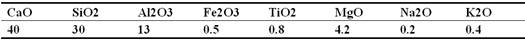

[0050] Table 2 Composition of blast furnace slag

[0051]

[0052] Table 3 Composition of desulfurized gypsum

[0053]

[0054] Table 4 Composition of arsenopyrite

[0055]

[0056] A method for solidifying arsenic with multiple solid waste cementitious materials for downhole filling at low cost, the specific steps are as follows:

[0057] (1) Grind cement, metakaolin, blast furnace slag, and desulfurized gypsum to 200 mesh respectively, dry in a drying oven at 105°C and sieve to obtain powder;

[0058]...

Embodiment 2

[0069] In this example, metakaolin comes from a factory in Henan, and its main components are shown in Table 1; blast furnace slag comes from a smelter in Southwest China, and its main components are shown in Table 2; desulfurized gypsum comes from a smelter in Shandong, and its main components are shown in Table 3 The arsenopyrite comes from a mining area in Jiangxi, and the main components are as shown in Table 4;

[0070] Table 1 Metakaolin composition

[0071]

[0072] Table 2 Composition of blast furnace slag

[0073]

[0074] Table 3 Composition of desulfurized gypsum

[0075]

[0076] Table 4 Composition of arsenopyrite

[0077]

[0078] A method for solidifying arsenic with multiple solid waste cementitious materials for downhole filling at low cost, the specific steps are as follows:

[0079] (1) Grind cement, metakaolin, blast furnace slag, and desulfurized gypsum to 200 mesh respectively, dry in a drying oven at 105°C and sieve to obtain powder;

[0...

Embodiment 3

[0091] In this example, metakaolin comes from a factory in Henan, and its main components are shown in Table 1; blast furnace slag comes from a smelter in Southwest China, and its main components are shown in Table 2; desulfurized gypsum comes from a smelter in Shandong, and its main components are shown in Table 3 The arsenopyrite comes from a mining area in Jiangxi, and the main components are as shown in Table 4;

[0092] Table 1 Metakaolin composition

[0093]

[0094] Table 2 Composition of blast furnace slag

[0095]

[0096] Table 3 Composition of desulfurized gypsum

[0097]

[0098] Table 4 Composition of arsenopyrite

[0099]

[0100] A method for solidifying arsenic with multiple solid waste cementitious materials for downhole filling at low cost, the specific steps are as follows:

[0101] (1) Grind cement, metakaolin, blast furnace slag, and desulfurized gypsum to 200 mesh respectively, dry in a drying oven at 105°C and sieve to obtain powder;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com