Water-based weather-resistant self-cleaning coating and preparation method and application thereof

A weather-resistant and self-cleaning technology, used in antifouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve the problems of easy brittle cracking, easy sticking back, poor self-cleaning properties, etc., to improve adhesion and temperature resistance. Change and improve the effect of sag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

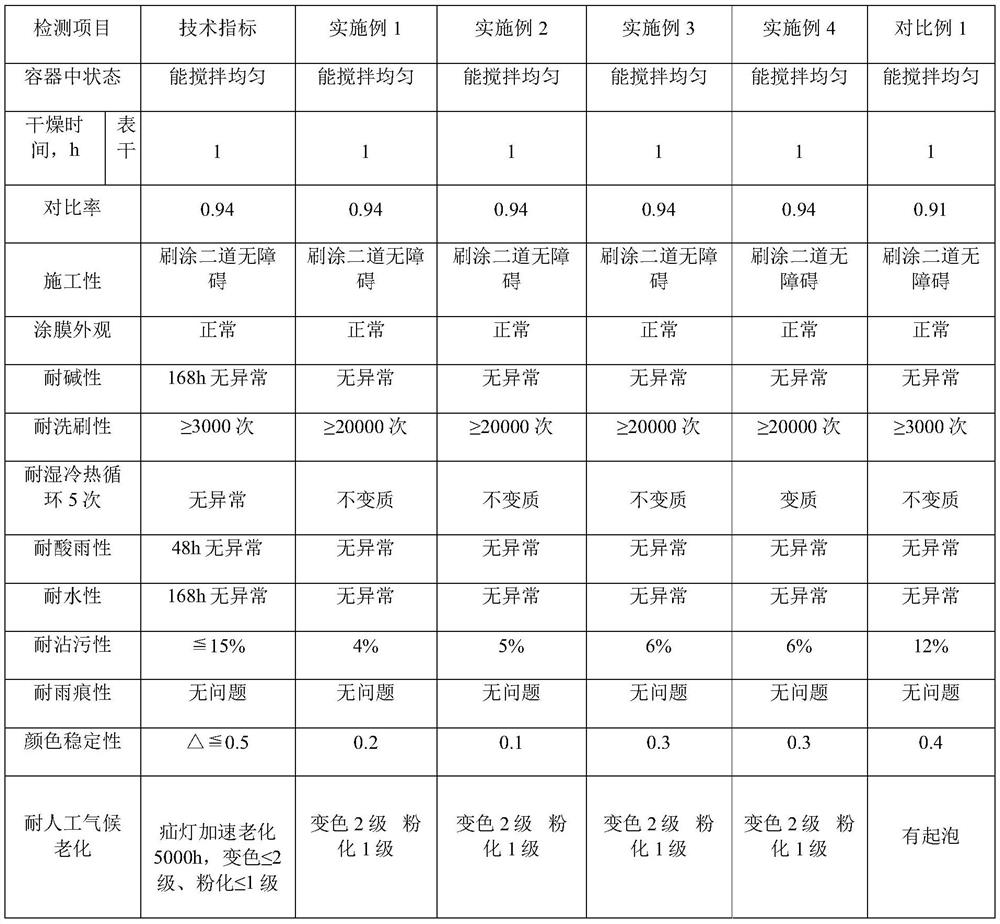

Examples

Embodiment 1

[0055] The present embodiment provides a water-based weather-resistant self-cleaning coating, and its preparation method is as follows:

[0056] (1) Add 15kg of deionized water into the reaction tank, then add 0.1kg of bactericide, 0.25kg of cellulose, 0.5kg of dispersant, 0.15kg of wetting agent, 12kg of antifreeze and 12kg of synthetic Membrane aid, after adding, continue to stir at a stirring speed of 150rpm for 5min;

[0057] (2) Continue to add 18kg rutile titanium dioxide, 3kg nano-titanium dioxide, 3kg kaolin, and 12kg heavy calcium to the reaction tank in sequence. After the addition is complete, stir at a stirring speed of 1200rpm for 30min until uniform, and then use a scraper fineness meter to scrape finely When the fineness is 55um, the prepared slurry is obtained;

[0058] (3) Add 40kg of water-based fluorocarbon emulsion resin and 0.4kg of defoamer to the stock slurry in turn, then stir at a stirring rate of 700rpm for 10min until uniform; then add 0.5kg of leve...

Embodiment 2

[0061] The present embodiment provides a water-based weather-resistant self-cleaning coating, and its preparation method is as follows:

[0062] (1) Add 18kg of deionized water into the reaction tank, then add 0.15kg of bactericide, 0.3kg of cellulose, 0.7kg of dispersant, 0.25kg of wetting agent, 16kg of antifreeze and 10kg of synthetic Membrane aid, after adding, continue to stir at a stirring speed of 150rpm for 5min;

[0063] (2) Continue to add 20kg of rutile titanium dioxide, 5kg of nano-titanium dioxide, 4kg of kaolin, and 10kg of heavy calcium to the reaction tank in sequence. After the addition is completed, stir at a stirring speed of 1200rpm for 30min until uniform, and then use a scraper fineness meter to scrape finely When the fineness is 50um, prepare the slurry;

[0064] (3) Add 45kg of water-based fluorocarbon emulsion resin and 0.6kg of defoamer to the stock slurry in turn, then stir at a stirring rate of 700rpm for 10min until uniform; then add 0.8kg of leve...

Embodiment 3

[0067] The present embodiment provides a water-based weather-resistant self-cleaning coating, and its preparation method is as follows:

[0068] (1) Add 20kg of deionized water into the reaction tank, and then add 0.2kg of bactericide, 0.2kg of cellulose, 0.6kg of dispersant, 0.2kg of wetting agent, 15kg of antifreeze and 15kg of component at a stirring speed of 150rpm. Membrane aid, after adding, continue to stir at a stirring speed of 150rpm for 5min;

[0069] (2) Continue to add 22kg rutile titanium dioxide, 5kg nano-titanium dioxide, 5kg kaolin, and 15kg heavy calcium to the reaction tank in sequence. After the addition is completed, stir at a stirring speed of 1200rpm for 30min until uniform, and then use a scraper fineness meter to scrape finely When the fineness is 45um, the prepared slurry is obtained;

[0070] (3) Add 42kg of water-based fluorocarbon emulsion resin and 0.2kg of defoamer to the stock slurry in turn, then stir at a stirring rate of 700rpm for 10min unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com