PTC ceramic sintering sagger and using method thereof

A saggar and ceramic technology, applied in the field of PTC ceramic sintering saggar, can solve problems such as uneven sintering heat, scattered sintering resistance, abnormal color of the edge of ceramic sheets, etc., to improve concentration, ensure consistency, and avoid edge color abnormal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

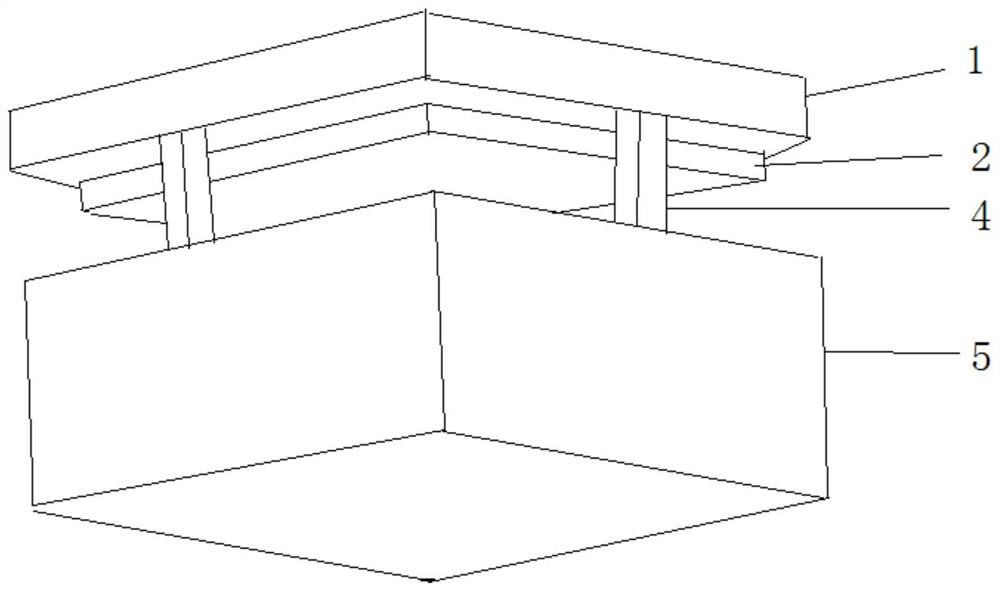

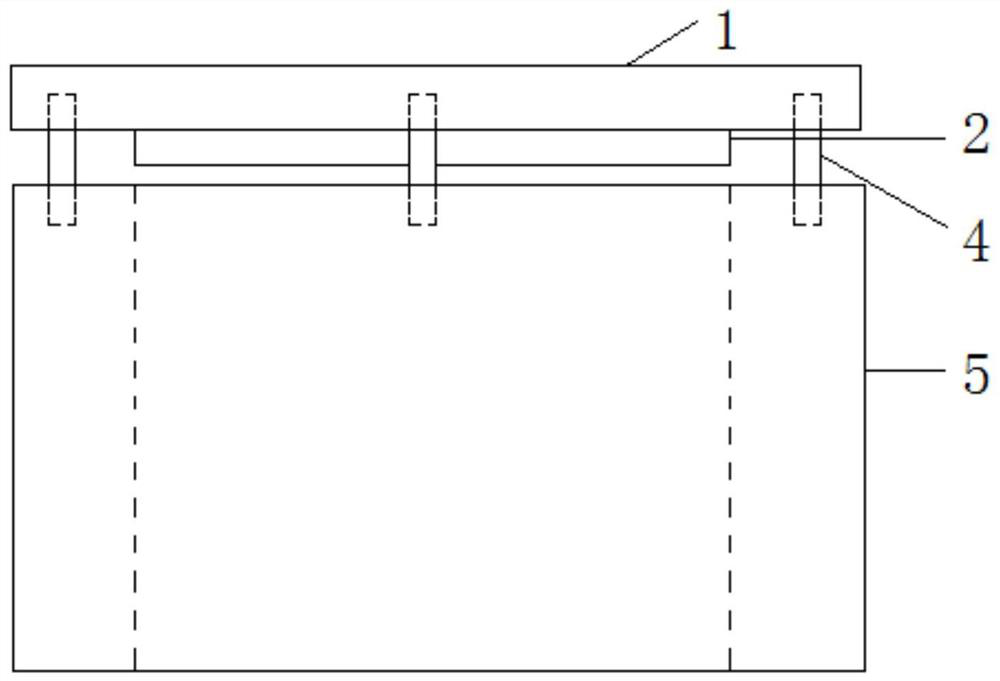

[0037] The using method of the PTC ceramic sintered sagger provided by the present embodiment comprises the following steps:

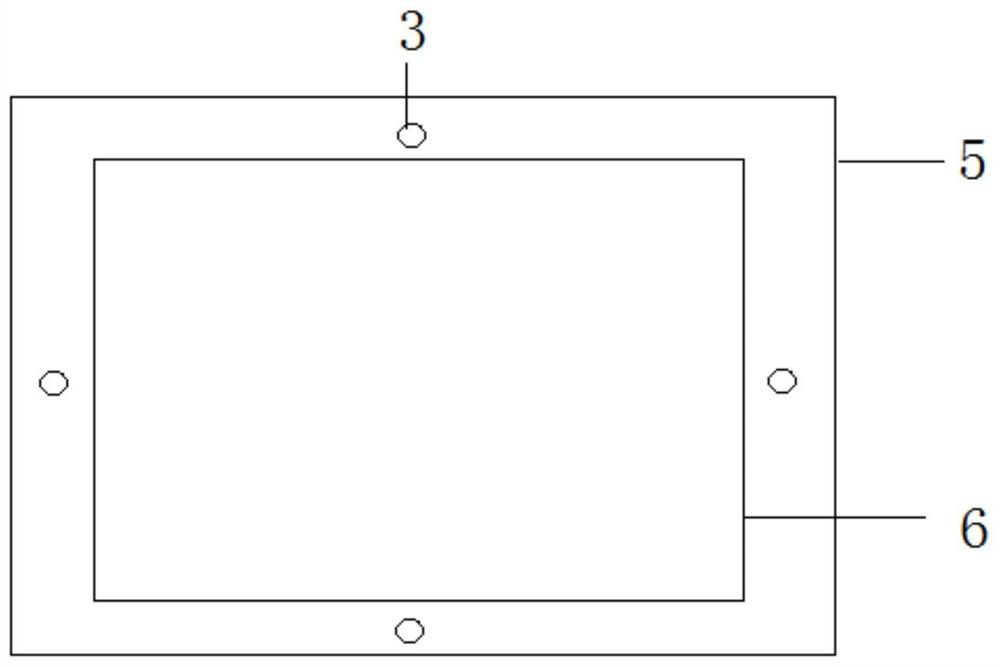

[0038] S1. Use mullite to make the upper cover plate and the bowl body of the square PTC ceramic sintered sagger, set a reserved hole on the four sides of the top opening of the bowl body, and set a hole corresponding to the reserved hole on the bottom of the upper cover plate Reserved hole.

[0039] S2. A zirconia plate with a thickness of 6mm is placed on the bottom of the bowl;

[0040]S3. Insert the formed PTC blank into the bowl, sprinkle 50-80 mesh zirconium powder in the gap between the blanks, and use a zirconia plate with a thickness of 2-3mm to block the contact surface between the blank and the bowl. , install graphite strips of corresponding specifications into the reserved holes on the top of the bowl, and close the upper cover according to the position of the corresponding reserved holes;

[0041] S4. In order to obtain PTC ceramics wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com