Foaming cement preparation process capable of detecting internal cracking

A technology of foamed cement and preparation process, which is applied in the direction of ceramic products, optical testing flaws/defects, applications, etc., which can solve problems such as anti-seepage, performance reduction of thermal insulation indicators, shortened service life of cement, and decline in overall strength, so as to avoid potential risk, prolonging service life, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

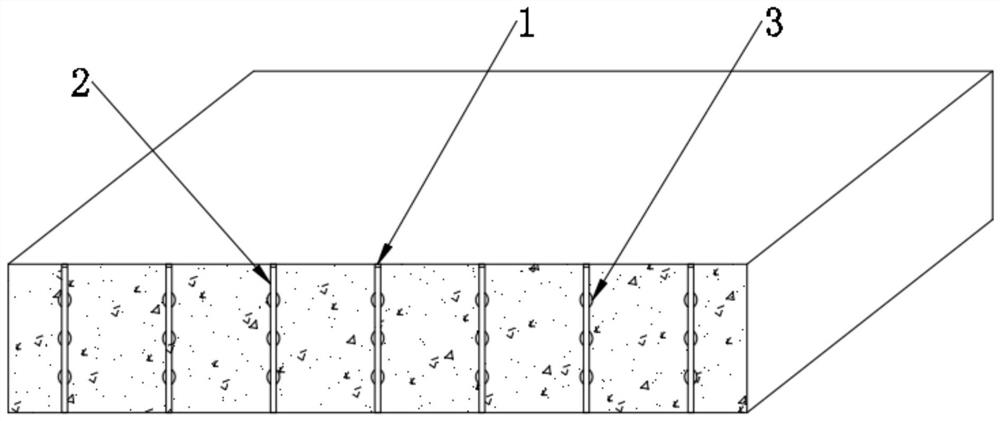

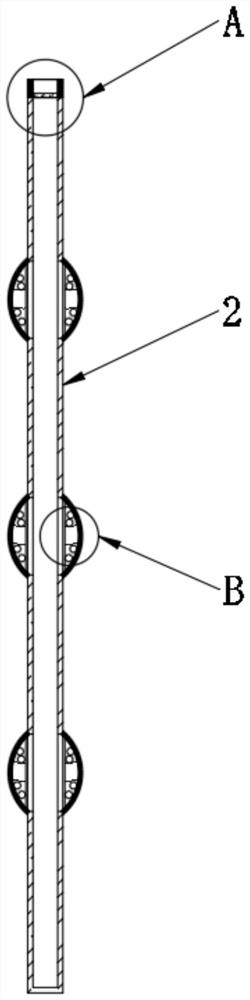

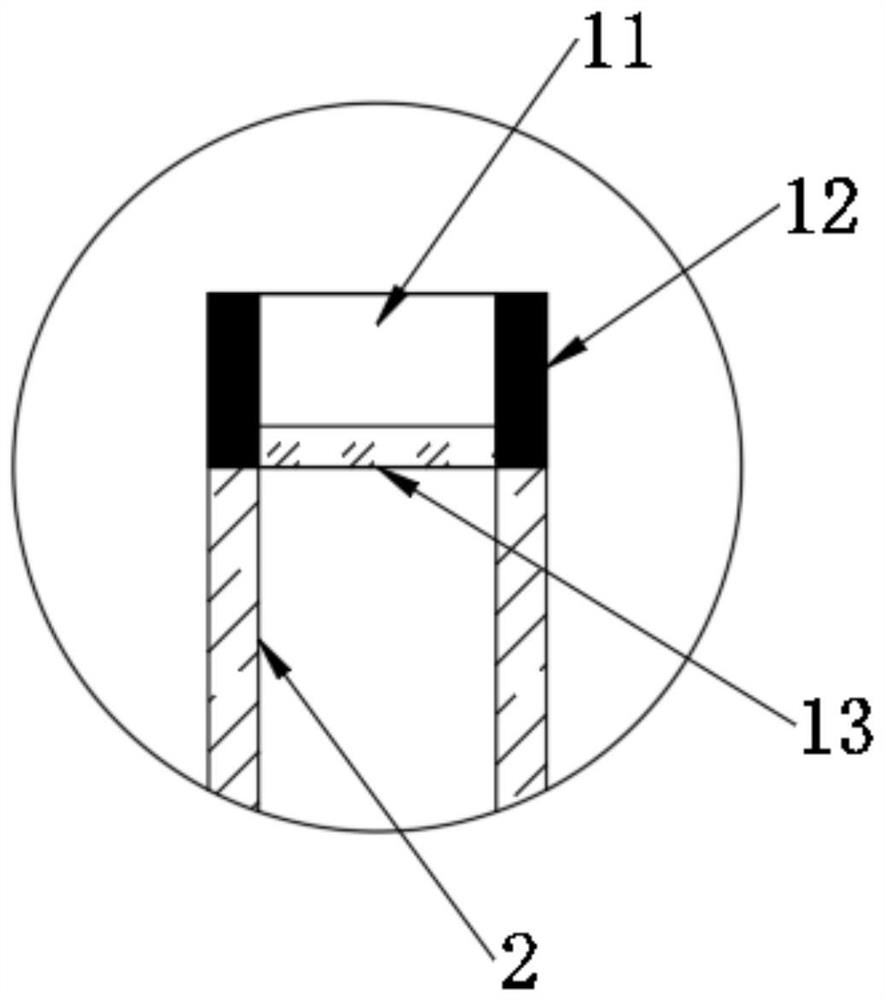

[0047] see figure 1 , a process for preparing foamed cement capable of detecting internal cracking, comprising the steps of:

[0048] S1. Take 60 parts of cement, 20 parts of fly ash, 2 parts of foam stabilizer, and 5 parts of fine sand according to the parts by weight, and stir for 40 minutes under the condition that the rotating speed is 500r / min to prepare a premix;

[0049] S2. Mix the premix and distilled water according to the mass ratio of 1:10 and put them into the mold, and take an appropriate number of pre-embedded rods and evenly embed them in the mold;

[0050] S3. Pressurize and feed the mold until the cavity remains saturated, keep the temperature at 45°C, and perform foam molding at one time, and the foaming time is 6 hours;

[0051] S4. After the foaming is completed, the foamed cement is removed from the mold, and then cured. After the curing, the surface is trimmed to ensure that the end of the pre-embedded rod is exposed to the surface of the foamed cement;...

Embodiment 2

[0063] A process for preparing foamed cement capable of detecting internal cracks, comprising the following steps:

[0064] S1. According to the parts by weight, take 70 parts of cement, 25 parts of fly ash, 4 parts of foam stabilizer, and 10 parts of fine sand, and stir for 50 minutes at a rotating speed of 550r / min to prepare a premix;

[0065] S2. Mix the premix and distilled water according to the mass ratio of 1:10 and put them into the mold, and take an appropriate number of pre-embedded rods and evenly embed them in the mold;

[0066]S3. Pressurize and feed the mold until the cavity remains saturated, keep the temperature at 50°C, and perform foam molding at one time, and the foaming time is 7 hours;

[0067] S4. After the foaming is completed, the foamed cement is removed from the mold, and then cured. After the curing, the surface is trimmed to ensure that the end of the pre-embedded rod is exposed to the surface of the foamed cement;

[0068] S5. Cut the foamed ceme...

Embodiment 3

[0071] A process for preparing foamed cement capable of detecting internal cracks, comprising the following steps:

[0072] S1. According to the parts by weight, take 80 parts of cement, 30 parts of fly ash, 5 parts of foam stabilizer, and 15 parts of fine sand, and stir for 60 minutes under the condition that the rotating speed is 600r / min to prepare the premix;

[0073] S2. Mix the premix and distilled water according to the mass ratio of 1:10 and put them into the mold, and take an appropriate number of pre-embedded rods and evenly embed them in the mold;

[0074] S3. Pressurize and feed the mold until the cavity remains saturated, keep the temperature at 55°C, and perform foam molding at one time, and the foaming time is 8 hours;

[0075] S4. After the foaming is completed, the foamed cement is removed from the mold, and then cured. After the curing, the surface is trimmed to ensure that the end of the pre-embedded rod is exposed to the surface of the foamed cement;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com