Lightweight, super-high-strength, corrosion-resistant, weldable titanium alloy wire rope for cranes and preparation method thereof

A titanium alloy, ultra-high-strength technology, applied in textiles, papermaking, textile cables, etc., can solve the problems of titanium alloy materials that do not meet the preparation process requirements and strength levels of ultra-fine wires, easily broken wires, poor process plasticity, etc., and achieve excellent Anti-corrosion performance and anti-fouling performance, the effect of good technical application and market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

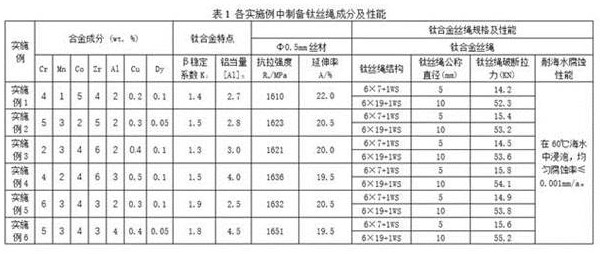

[0033]Embodiment 1: Ti-4Cr-Mn-5Co-4Zr-2Al-0.2Cu-0.1Dy alloy

[0034] 1) Weigh the raw materials according to the ingredients listed in Example 1, and calculate as 4.0wt.% chromium, 1.0wt.% manganese, 5.0wt.% cobalt, 4.0wt.% zirconium, 2.0wt.% aluminum, 0.2wt.% Copper, 0.1wt.% Dysprosium and industrial grade 1 sponge titanium composition ratio vacuum melting to prepare titanium alloy ingots,

[0035] 2) Blank forging and machining. After the ingot is heated, it is blanked on the press. The blanking temperature is 1100°C, the final forging temperature is 900°C, the single upsetting deformation is 40%, and the total deformation is 110%; Then it is forged into bars through multiple fires on hydraulic presses or extruders. The forging temperature is 950°C, the final forging temperature is 750°C, and the deformation of a single upsetting is 60%. Finally, it is forged into Φ65×1100mm bars, and Processed into Φ50×1000mm light rod.

[0036] 3) Preparation of titanium alloy wire rod. ...

Embodiment 2

[0041] Example 2: Ti-5Cr-3Mn-2Co-5Zr-2Al-0.3Cu-0.05Dy alloy

[0042] Weigh the raw materials according to the ingredients listed in Example 2, and calculate by 5.0wt.% chromium, 3.0wt.% manganese, 2.0wt.% cobalt, 5.0wt.% zirconium, 2.0wt.% aluminum, 0.3wt.% copper, 0.05wt.% Dysprosium and industrial grade 1 titanium sponge are proportioned to prepare titanium alloy ingots by vacuum smelting, and then the same steps as 2-8 in Example 1 are used to prepare titanium alloy wire ropes. The properties of the titanium alloy wire rope are shown in Table 1.

Embodiment 3

[0043] Embodiment 3: Ti-2Cr-3Mn-4Co-6Zr-2Al-0.4Cu-0.1Dy alloy

[0044] Weigh the raw materials according to the ingredients listed in Example 3, and calculate by 2.0wt.% chromium, 3.0wt.% manganese, 4.0wt.% cobalt, 6.0wt.% zirconium, 2.0wt.% aluminum, 0.4wt.% copper, 0.1wt.% Dysprosium and industrial grade 1 titanium sponge are proportioned to prepare titanium alloy ingots by vacuum smelting, and then the same steps 2-8 as described in Example 1 are used to prepare titanium alloy wire ropes. The properties of the titanium alloy wire rope are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com