Light ultrahigh-strength and corrosion-resistant weldable titanium alloy wire rope for crane and preparation method of titanium alloy wire rope

A technology of titanium alloy and cranes, which is applied in the field of lightweight, ultra-high-strength, corrosion-resistant, weldable titanium alloy wire ropes for cranes and its preparation field, which can solve the problem of titanium alloy materials that do not meet the requirements of the preparation process of ultra-fine wires and the strength level, and easily broken wires , poor process plasticity and other issues, to achieve good technical application and market prospects, excellent corrosion resistance and antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

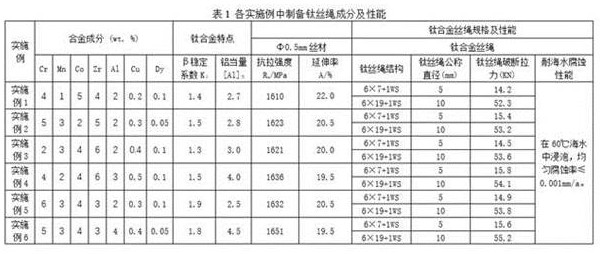

[0033]Embodiment 1: Ti-4Cr-Mn-5Co-4Zr-2Al-0.2Cu-0.1Dy alloy

[0034] 1) Weigh the raw materials according to the ingredients listed in Example 1, and calculate as 4.0wt.% chromium, 1.0wt.% manganese, 5.0wt.% cobalt, 4.0wt.% zirconium, 2.0wt.% aluminum, 0.2wt.% Copper, 0.1wt.% Dysprosium and industrial grade 1 sponge titanium composition ratio vacuum melting to prepare titanium alloy ingots,

[0035] 2) Blank forging and machining. After the ingot is heated, it is blanked on the press. The blanking temperature is 1100°C, the final forging temperature is 900°C, the single upsetting deformation is 40%, and the total deformation is 110%; Then it is forged into bars through multiple fires on hydraulic presses or extruders. The forging temperature is 950°C, the final forging temperature is 750°C, and the deformation of a single upsetting is 60%. Finally, it is forged into Φ65×1100mm bars, and Processed into Φ50×1000mm light rod.

[0036] 3) Preparation of titanium alloy wire rod. ...

Embodiment 2

[0041] Example 2: Ti-5Cr-3Mn-2Co-5Zr-2Al-0.3Cu-0.05Dy alloy

[0042] Weigh the raw materials according to the ingredients listed in Example 2, and calculate by 5.0wt.% chromium, 3.0wt.% manganese, 2.0wt.% cobalt, 5.0wt.% zirconium, 2.0wt.% aluminum, 0.3wt.% copper, 0.05wt.% Dysprosium and industrial grade 1 titanium sponge are proportioned to prepare titanium alloy ingots by vacuum smelting, and then the same steps as 2-8 in Example 1 are used to prepare titanium alloy wire ropes. The properties of the titanium alloy wire rope are shown in Table 1.

Embodiment 3

[0043] Embodiment 3: Ti-2Cr-3Mn-4Co-6Zr-2Al-0.4Cu-0.1Dy alloy

[0044] Weigh the raw materials according to the ingredients listed in Example 3, and calculate by 2.0wt.% chromium, 3.0wt.% manganese, 4.0wt.% cobalt, 6.0wt.% zirconium, 2.0wt.% aluminum, 0.4wt.% copper, 0.1wt.% Dysprosium and industrial grade 1 titanium sponge are proportioned to prepare titanium alloy ingots by vacuum smelting, and then the same steps 2-8 as described in Example 1 are used to prepare titanium alloy wire ropes. The properties of the titanium alloy wire rope are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com