A kind of parabolic polyimide film and preparation method thereof

A technology of polyimide film and polyimide, which is applied in the field of polymer materials, can solve problems such as high energy consumption and limited practical application, meet the requirements of simple experimental conditions, achieve uniformity and controllability, and implement process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

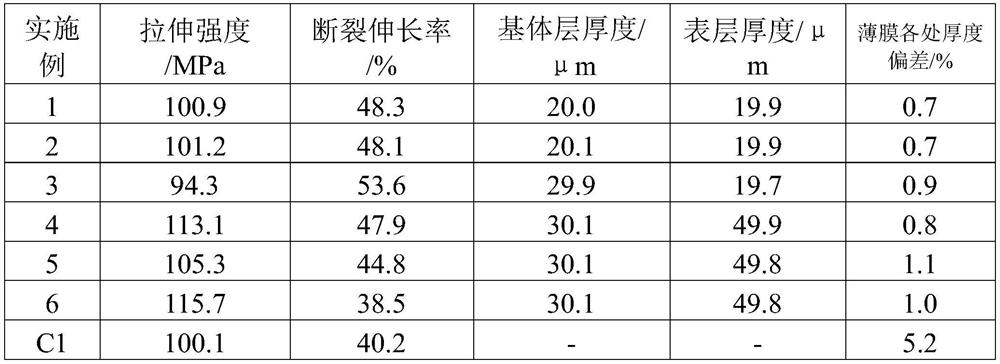

Embodiment 1

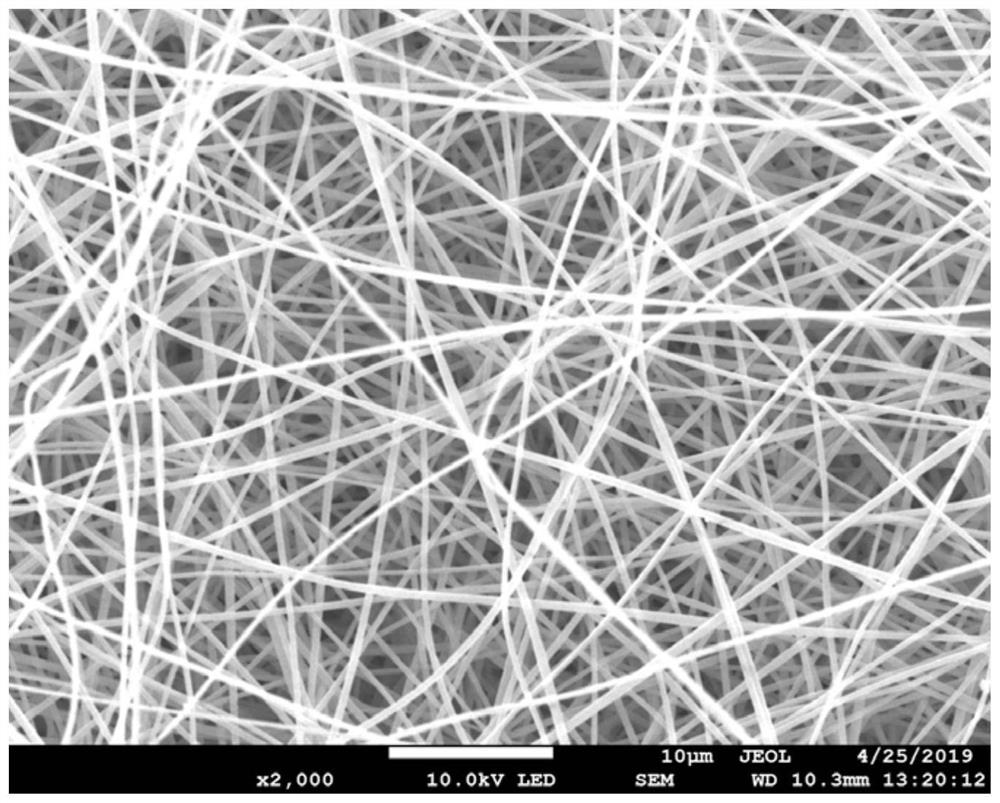

[0027] A. Using BTDA and ODA as monomers to synthesize a polyamic acid solution with a solid content of 12wt% in DMAc with a curvature of 5m -1 A parabolic polyamic acid nanofiber membrane with a thickness of 20 μm was spun by electrospinning on the parabolic substrate;

[0028] B. The nanofiber membrane obtained in step A is cyclized by heat treatment at 300° C. for 120 min to form a parabolic anchored polyimide network insoluble in DMAc;

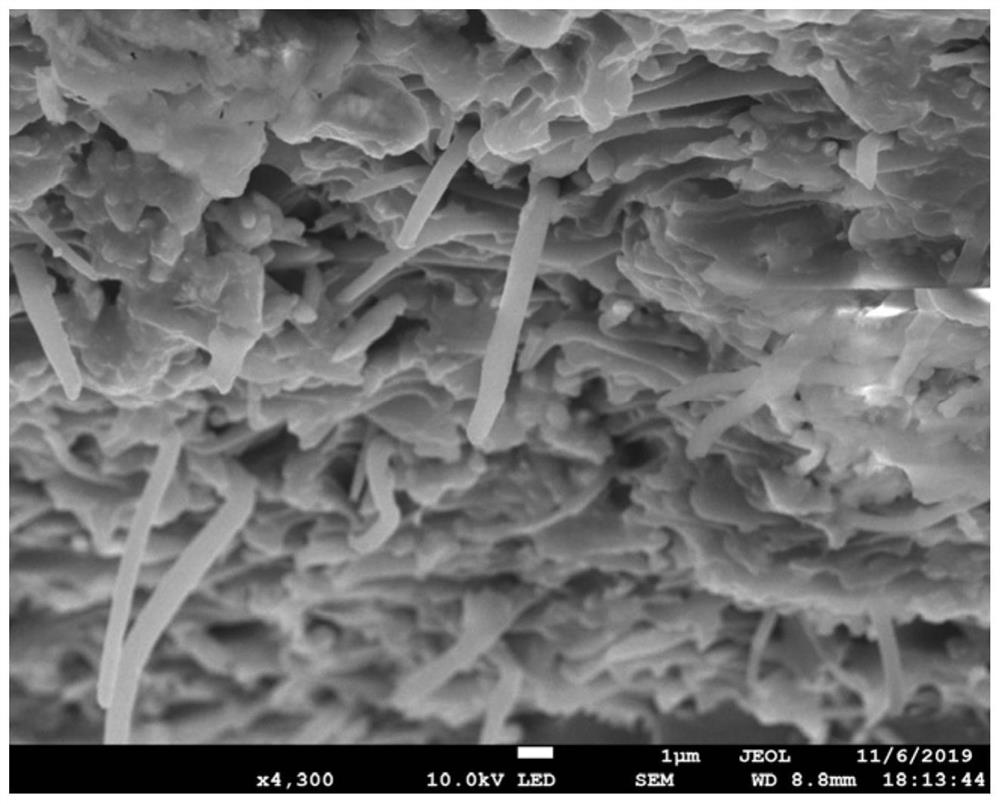

[0029] C. Cast a layer of PAA with a thickness of 200 μm in a BPDA-ODA system with a solid content of 5 wt% on the parabolic anchored polyimide network obtained in step B, and then place it in a vacuum oven at 80 °C for 5 hours to evaporate the solvent , PAA is adsorbed on the polyimide network and is mutually dissolved and cured to obtain a film with a PAA / PI interpenetrating network structure;

[0030] D. The film obtained in step C is placed in an oven for heat treatment at 300° C. for 6 hours, to obtain a parabolic polyimide film.

Embodiment 2

[0032] A. Using BTDA and ODA as monomers to synthesize a polyamic acid solution with a solid content of 12wt% in DMAc at a curvature of 10m -1 A parabolic polyamic acid nanofiber membrane with a thickness of 20 μm was spun by electrospinning on the parabolic substrate;

[0033] B. The nanofiber membrane obtained in step A is cyclized by heat treatment at 300° C. for 120 min to form a parabolic anchored polyimide network insoluble in DMAc;

[0034] C. Cast a layer of PAA with a thickness of 200 μm in a BPDA-ODA system with a solid content of 5 wt% on the parabolic anchored polyimide network obtained in step B, and then place it in a vacuum oven at 80 °C for 5 hours to evaporate the solvent , PAA is adsorbed on the polyimide network and is mutually dissolved and cured to obtain a film with a PAA / PI interpenetrating network structure;

[0035] D. The film obtained in step C is placed in an oven for heat treatment at 300° C. for 6 hours, to obtain a parabolic polyimide film.

Embodiment 3

[0037] A. Using BTDA and ODA as monomers to synthesize a polyamic acid solution with a solid content of 12wt% in DMAc at a curvature of 10m -1 A parabolic polyamic acid nanofiber membrane with a thickness of 30 μm was spun by electrospinning on the parabolic substrate;

[0038] B. The nanofiber membrane obtained in step A is cyclized by heat treatment at 300° C. for 120 min to form a parabolic anchored polyimide network insoluble in DMAc;

[0039] C. Cast a layer of PAA with a thickness of 200 μm in a BPDA-ODA system with a solid content of 5 wt% on the parabolic anchored polyimide network obtained in step B, and then place it in a vacuum oven at 80 °C for 5 hours to evaporate the solvent , PAA is adsorbed on the polyimide network and is mutually dissolved and cured to obtain a film with a PAA / PI interpenetrating network structure;

[0040] D. The film obtained in step C is placed in an oven for heat treatment at 300° C. for 6 hours, to obtain a parabolic polyimide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com