Adhesive with high electrical and thermal conductivity and preparation method thereof

A technology of conductive adhesive and conductive filler, used in conductive adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of long production process, complex process, low efficiency, etc., to reduce system viscosity, improve electrical conductivity and thermal conductivity. performance, the effect of improving colloid compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to another aspect of the present invention, a method for preparing the above-mentioned conductive adhesive is provided. The preparation method comprises the following steps: uniformly dispersing epoxy resin, toughening agent, curing agent, curing accelerator, coupling agent, thixotropic agent, solvent and conductive filler to prepare conductive adhesive; preferably, the preparation method It also includes the step of adding a silver powder surface treatment agent.

[0027] According to yet another aspect of the present invention, an application of the above-mentioned conductive adhesive in electronic packaging is provided.

Embodiment 1

[0030] First, pre-mix the resin matrix, take 2.7g bisphenol A epoxy resin, add 0.3g polyether polyol, and carry out polyether toughening modification. Add 0.75g multifunctional epoxy resin (trimethylolethane triglycidyl ether), 0.75g core-shell toughening agent carries out toughening modification to epoxy resin, obtains the evenly dispersed resin matrix after grinding for 10 minutes, and then Add 3g acid anhydride curing agent (phenylone tetra-acid dianhydride), 0.04g imidazole accelerator (2-ethyl 4-methylimidazole), coupling agent 0.02g (KH560) and thixotropic agent 0.04g (fumed silica ) after grinding for 10 minutes, carry out ultrasonic dispersion to mix the auxiliary agent and resin evenly, then mechanically evacuate and defoam for 30 minutes, take out the cuvette to obtain the organic mixture, add 30g of flake silver powder with an average particle size of 3 μm and a tap density of 6g / cc, 6g flake silver powder with an average particle size of 10μm and a tap density of 3...

Embodiment 2

[0032]First, pre-mix the resin matrix, take 0.9g novolak epoxy resin, 1.8g bisphenol A epoxy resin, add 0.3g polyether polyol, and carry out polyether toughening modification. Add 0.75g multifunctional epoxy resin (cyclohexyl dimethanol diglycidyl ether), 0.75g core-shell toughening agent to toughen and modify the epoxy resin, and grind for 10 minutes to obtain a uniformly dispersed resin matrix, then add 3g Anhydride curing agent (tetrahydrophthalic anhydride), 0.4g imidazole accelerator (2-methylimidazole), 0.2g coupling agent (KH550) and 0.04g thixotropic agent (organic bentonite) were ground for 10 minutes and then ultrasonically Disperse to mix the additives and resin evenly, then mechanically vacuumize and defoam for 30 minutes, take out the cuvette to obtain the organic mixture, add 42g of spherical silver powder with an average particle size of 2μm and a tap density of 6g / cc, with an average particle size of 6μm and a tap density of 6g Flake silver powder with a densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

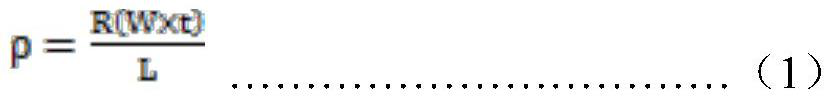

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com