A graphene-based composite phase change material with hierarchical thermal conductivity structure and preparation method thereof

A technology of composite phase change material and thermal conduction structure, applied in the field of graphene-based composite phase change material and its preparation, can solve the problems of loose structure, weak interaction of thermal conduction materials, limited thermal conduction efficiency of skeleton, etc., and achieve high enthalpy retention. rate, the effect of improving thermal response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take 50.0 g of graphene oxide dispersion liquid with a concentration of 0.5 wt%, add 500 mg of graphene nanosheets, stir at room temperature at 1000 rpm for 1 hour, and obtain graphene nanosheets / graphene oxide slurry.

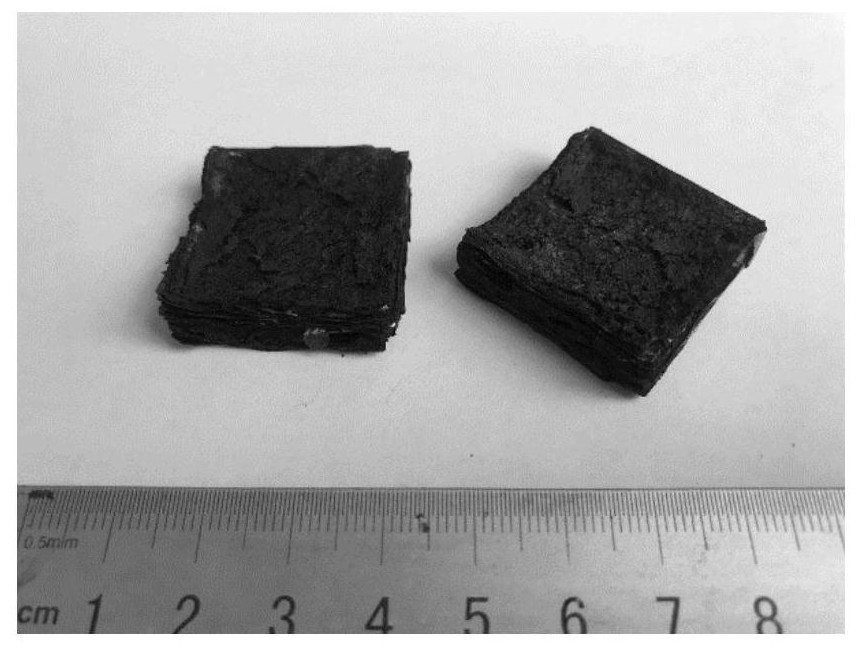

[0026] (2) Lay the two-dimensional graphene film with high thermal conductivity and the graphene nanosheet / graphene oxide slurry layer by layer, and control the distance between the layers of the two-dimensional graphene film with high thermal conductivity to be 1mm. The paved samples were frozen in a liquid nitrogen (-196°C) environment for 15 minutes, and then dried in a freeze dryer for 70 hours to obtain a porous skeleton with a hierarchical thermal conductivity structure. The freeze-drying temperature was -60°C and the pressure is 30Pa.

[0027] (3) Heating the solid paraffin to 80° C. until it is completely liquefied, immersing the porous skeleton obtained in step (2) in the liquefied paraffin, and raising the vacuum degree of the immersion en...

Embodiment 2

[0031] According to Example 1, the thermally conductive filler graphene nanosheets in Step (1) of Example 1 are changed to single-layer graphene, and the addition amount is changed to 1000 mg, and the rest are the same as in Example 1 to obtain a fast-response compound with a hierarchical thermal conductivity structure. phase change material. The paraffin loading is 72.1wt%, the directional thermal conductivity is 40.5W / m.K, the phase transition enthalpy is 155J / g, and the phase transition temperature is 40°C.

Embodiment 3

[0033] According to Example 1, the layer spacing of the high thermal conductivity graphene two-dimensional film in Step (2) of Example 1 is changed to 0.5mm. The rest are the same as in Example 1, and a fast-response composite phase-change material with a hierarchical thermal conductivity structure is obtained. Wherein the paraffin loading is 70.1wt%, the directional thermal conductivity is 50.3W / m.K, the phase transition enthalpy is 152J / g, and the phase transition temperature is 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com