Infrared detector sensitive element based on nanometer infrared absorption layer and preparation method thereof

An infrared absorbing layer and infrared detector technology, applied in the field of infrared detectors, can solve problems such as complex processing technology, high cost, and difficult control of crystal thickness, and achieve the effect of simple processing technology, low cost, and improved thermal response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

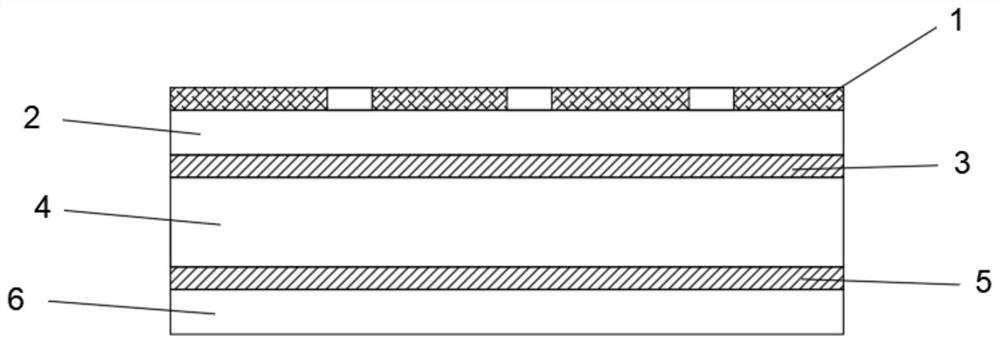

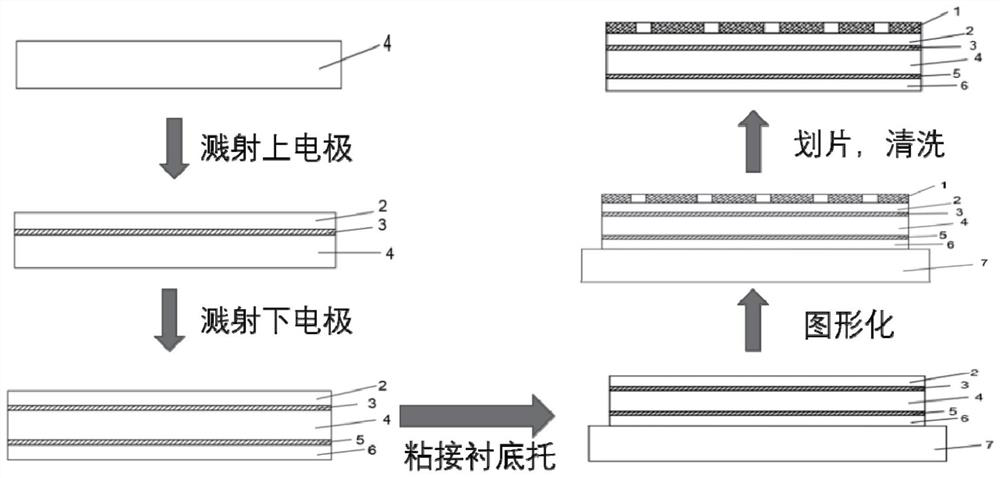

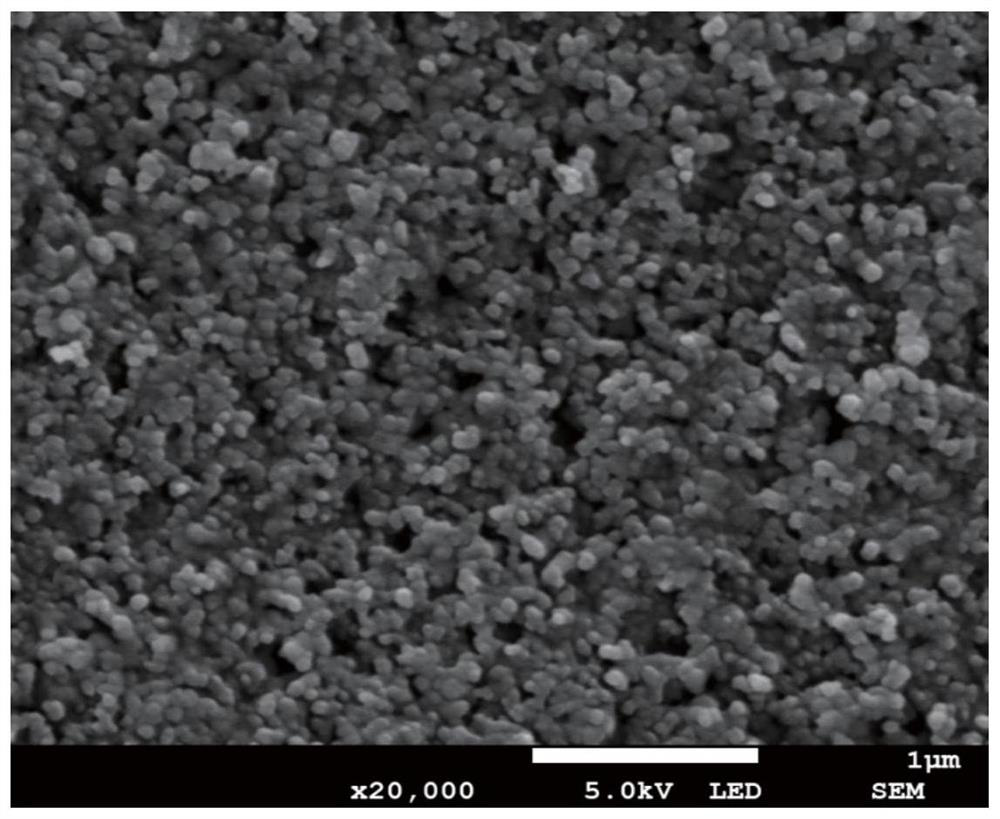

[0030] Such as figure 1 As shown, an infrared detector sensitive element based on a nano-absorbing layer, which includes an infrared-sensitive absorbing layer 1, an upper electrode layer 2, an upper electrode connecting layer 3, a pyroelectric thin layer 4, and a lower electrode connecting layer from top to bottom 5. The lower electrode layer 6 . The infrared sensitive absorbing layer 1 is a nanometer infrared absorbing layer with a small nano-cluster structure, and its thickness is 5 μm. The material of the upper electrode layer 2 is metal Cu film with a thickness of 300nm. The material of the upper electrode connection layer 3 is metal Ti thin film with a thickness of 15 nm. The pyroelectric thin layer 4 is a double-sided polished pyroelectric lithium tantalate crystal sheet with a thickness of 25 μm. The material of the lower electrode connecting layer 5 is Ti metal thin film with a thickness of 15nm. The material of the lower electrode layer 6 is metal A1 film with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com