Preparation method of green long-acting portable solid fragrance agent

A production method, portable technology, applied in disinfection, deodorization, etc., can solve the problems of VOC pollution, chronic poisoning, etc., achieve the effect of low residual oil rate, good mechanical strength, and eliminate the use of organic auxiliary reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

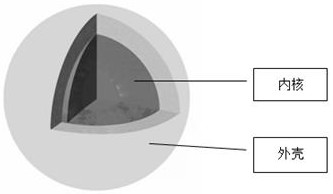

Embodiment approach 1

[0021] First, crush the colloidal grade attapulgite with a viscosity of 1000Pa⋅s to 300 meshes and dry it at 200°C for 2 hours, then cool it to room temperature for later use; take the processed colloidal grade attapulgite and add pure natural citrus essential oil according to the mass ratio of 3:1. The ratio is evenly mixed to make high-concentration raw materials, and put into sealed reagent bottle A for use. Take 2.5g of high-concentration raw material from the sealed reagent bottle A and use a tablet press with a pressure of 45KN to press it into a pill as the core; then take the processed colloid-grade attapulgite and add pure natural citrus essential oil according to the mass ratio of 30:1. Mix evenly to make low-concentration raw materials, and put them into sealed reagent bottle B for later use. From the sealed reagent bottle B, take low-concentration raw materials twice the weight of the core as the shell, and the shell will evenly wrap the pills, and perform secondar...

Embodiment approach 2

[0023] This embodiment is roughly the same as Embodiment 1, and the only difference is that the pressure of the tablet press is different. The high-concentration raw material with a quality of 2.5 g is compressed into a pill by a tablet press with a pressure of 50KN as the core; The tablet press pressure during secondary compression is 60KN.

[0024] The prepared green long-lasting portable solid fragrance with core-shell structure can volatilize fragrance for 3.3 months at room temperature, and the residual oil rate of essential oil is as low as 1.1%.

Embodiment approach 3

[0026] This embodiment is roughly the same as Embodiment 1, and the only difference is that the pressure of the tablet press is different. The high-concentration raw material with a quality of 2.5 g is compressed into a pill by a tablet press with a pressure of 40KNKg as the core; the pill wrapped in the shell The tablet press pressure when carrying out secondary compression is 50KNKg.

[0027] The prepared green long-lasting portable solid fragrance with core-shell structure can volatilize its fragrance for nearly 3 months at room temperature, and the residual oil rate of essential oil is as low as 1.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com