Plant waste based desulfurization wastewater treatment reagent as well as preparation process and application thereof

A plant waste and plant waste technology, which is applied in the field of plant waste-based desulfurization wastewater treatment reagents, can solve the problems of difficult and large-scale application, low waste utilization rate, low wastewater treatment efficiency, etc., so as to improve the utilization rate and improve Water quality, high value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

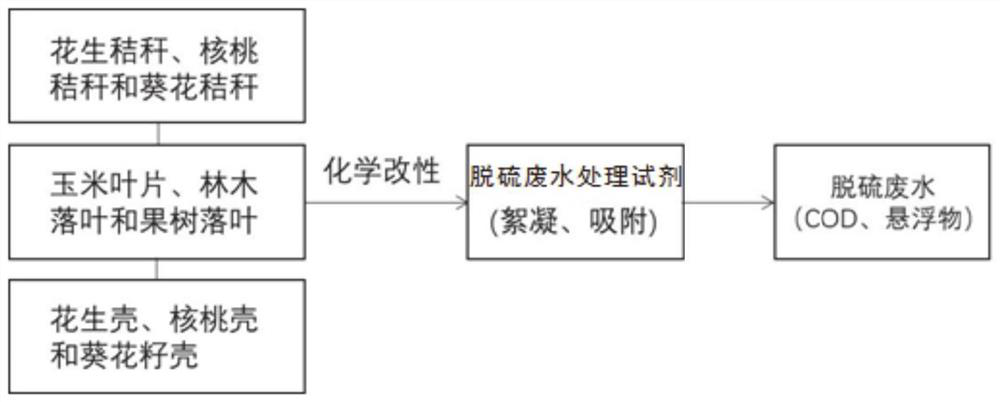

Method used

Image

Examples

Embodiment 1

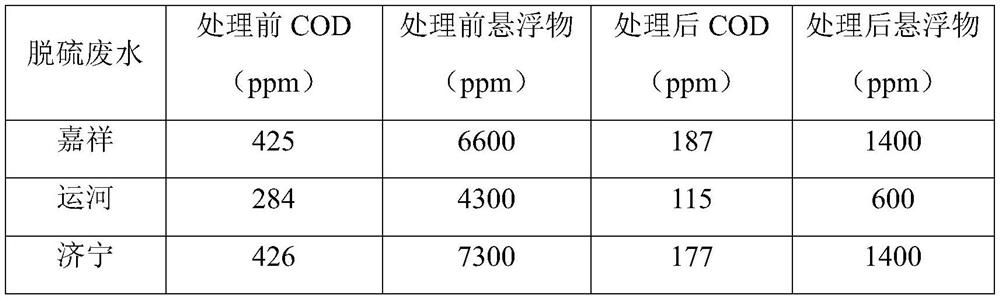

[0043] 1. Take the dried peanut stalks, walnut stalks and sunflower stalks, wash and remove the soil, mix and dry, and grind them with a pulverizer. Then prepare the preparation solution that the concentration of sulfuric acid is 1%, the concentration of sodium sulfate is 1%, and the concentration of iron sulfate is 2%, and the mixed fruit shell particles after the pulverization are added in the preparation solution, and the pressure reactor is used as the reaction vessel. The liquid is pressurized and heated at a pressure of 0.3MPa and a heating temperature of 110°C. After cooling, the straw particles are filtered and separated from the water body, washed three times with clean water, and dried to obtain a desulfurization wastewater treatment reagent.

[0044] 2. Taking the desulfurization wastewater of Huaneng Jiaxiang, Yunhe and Jining power plants as the treatment objects, the prepared reagents are used to treat the desulfurization wastewater.

[0045] 3. After the treatme...

Embodiment 2

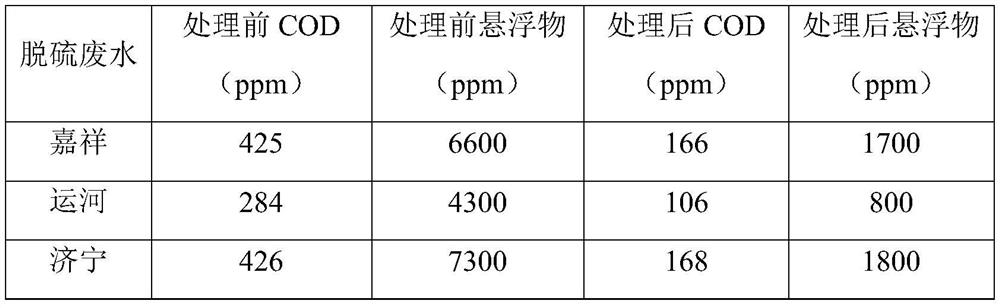

[0049] 1. Take the dried corn leaves, fallen leaves of forest trees and fallen leaves of fruit trees, wash and remove the soil, mix and dry, and pulverize with a pulverizer. The concentration of sulfuric acid is 3%, the concentration of sodium sulfate is 2%, and the concentration of iron sulfate is 2%. Add the crushed leaf particles into the preparation liquid, use the pressurized reactor as the reaction vessel, pressurize and heat the mixed liquid, the pressurized pressure is 0.3MPa, and the heating temperature is 100 ° C. After cooling, the straw The particles are separated from the water body by filtration, washed three times with clean water, and dried to obtain a desulfurization wastewater treatment reagent.

[0050] 2. Taking the desulfurization wastewater of Huaneng Jiaxiang, Yunhe and Jining power plants as the treatment objects, the prepared reagents are used to treat the desulfurization wastewater.

[0051] 3. After the treatment process, analyze the treated desulfur...

Embodiment 3

[0055] 1. Take the dried peanut shells, walnut shells and sunflower shells, wash and remove the soil, mix and dry, and pulverize with a pulverizer. The concentration of sulfuric acid is 1%, the concentration of sodium sulfate is 1%, and the concentration of iron sulfate is 2%. % of the preparation solution, the crushed fruit shell particles are added to the preparation solution, and the pressurized reactor is used as the reaction vessel to pressurize and heat the mixed solution. The pressurized pressure is 0.6MPa, and the heating temperature is 130°C. , the straw particles are filtered and separated from the water body, washed three times with clean water, and dried to obtain a desulfurization wastewater treatment reagent.

[0056] 2. Taking the desulfurization wastewater of Huaneng Jiaxiang, Yunhe and Jining power plants as the treatment objects, the prepared reagents are used to treat the desulfurization wastewater.

[0057] 3. After the treatment process, analyze the treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com